Universal drill sharpening machine

A drill bit sharpening and sharpening machine technology, which is used in drilling tool accessories, drilling/drilling equipment, boring machine/drilling machine components, etc., to achieve the effects of extending service life, high drilling accuracy and high sharpening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

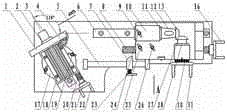

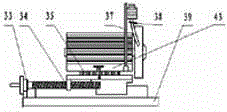

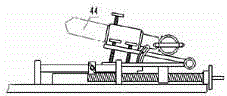

[0018] A kind of universal drill sharpening machine, such as figure 1 , 2 Shown in and 3: it comprises a sharpening machine chassis 39, and the grinding head 43 is fixed on one side of the sharpening machine chassis 39, and the drill bit 44 that cooperates with the grinding head 43 is fixed on the other side; The moving guide rail 3 and the grinding head moving guide rail 3 are successively installed with the grinding wheel 1 fixed by the grinding wheel pressing 2, the grinding head rotating disk 17, the grinding head power source 18 fixed on the grinding head rotating disk 17 from top to bottom. The grinding head moving screw 20 supported by 21 and the grinding head moving screw 22 that controls the grinding head moving screw are assembled; the drill bit 44 includes an upper drill bit holder moving guide rail 6, a middle drill bit holder moving lead screw 8. The lower part of the drill holder moves the positioning screw 5, the drill holder moves the guide rail 6, and then co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com