Supported metal palladium catalyst, its preparation and its application

A metal palladium, supported technology, applied in the dynamic kinetic resolution of secondary alcohols, supported metal palladium catalyst and its preparation, can solve the problems of restricting wide application, cumbersome post-processing steps, and difficult separation of products in homogeneous catalytic systems , to achieve the effect of cost reduction and efficient splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

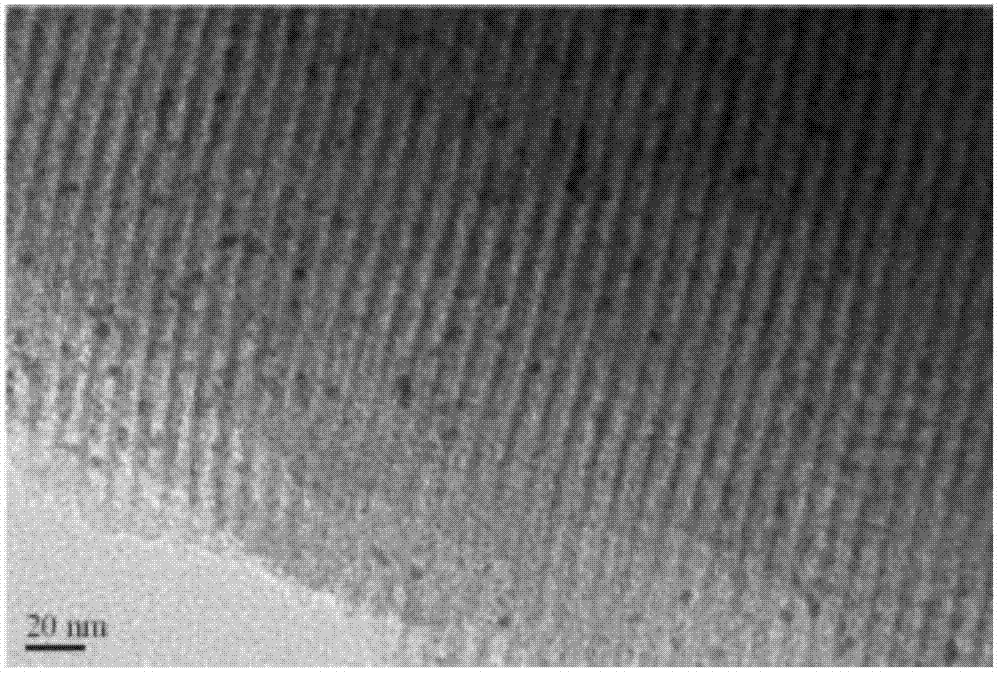

Image

Examples

Embodiment 1

[0019] (1) Under the protection of an inert gas, add 75 mg (0.246 mmol) of palladium acetylacetonate into 15 mL of oleylamine, stir until dissolved; heat the above solution to 60 °C within 10 minutes with a 4 °C / min program. Dissolve 300 mg (3.46 mmol) tert-butylamine borane in 3.5 mL oleylamine and quickly pour into the above palladium salt solution. The solution was programmed at 3°C / min to 90°C and then held at 90°C for 60 minutes. After cooling to room temperature, 30 mL of absolute ethanol was added, and the product was centrifuged at 8000 rpm and dispersed in 125 mL of n-hexane.

[0020] (2) Impregnate 0.3g of mesoporous silica SBA-15 with 50mL of metal palladium solution (containing 10mg of palladium) in Step 1 at 25°C, ultrasonically at 30W for 2 hours, centrifuge at 8000rmp, wash with ethanol, and vacuum dry at 90°C4 Hour.

[0021] (3) Add 20 mL of toluene to the product in step 2, add 2.5 mL of methyltriethoxysilane, and heat to reflux at 70° C. for 10 hours to obt...

Embodiment 2

[0025] The catalyst described in Example 1 is combined with biological enzymes for dynamic kinetic resolution of secondary alcohols. Namely: 0.5 mmol of racemic phenylethyl alcohol, 5 mL of n-hexane, 60 mg of supported metal palladium catalyst, 100 mg of Novozym 435 biological enzyme and 1.5 mmol of ethylene acetate were added to a 10 mL reaction kettle. Fill and discharge 4-5 times with 5% hydrogen-argon mixed gas to replace the air in the reactor, and finally control the partial pressure of hydrogen in the reactor to 0.03MPa. The reactor was placed in an oil bath at 70°C for 12 hours, cooled to room temperature, centrifuged, and the supernatant was filtered with a 0.2 μm filter head for chromatographic analysis. An ester of 98% conversion, 99.5% optical purity and 99% chemical purity was obtained.

Embodiment 3

[0027] (1) Under the protection of inert gas, add 75mg (0.246mmol) palladium acetylacetonate into 20mL oleylamine, stir until dissolved; heat the above solution to 60°C within 10 minutes at 4°C / min. Dissolve 300 mg (3.46 mmol) tert-butylamine borane in 3.5 mL oleylamine and quickly pour into the above palladium salt solution. The solution was programmed at 3°C / min to 90°C and then held at 90°C for 60 minutes. After cooling to room temperature, 30 mL of absolute ethanol was added, and the product was centrifuged at 8000 rpm and dispersed in 125 mL of n-hexane.

[0028] (2) Impregnate 0.3g of carrier mesoporous silica SBA-15 with 50mL of step 1 metal palladium solution (containing 10mg of palladium) at 25°C, ultrasonicate at 30W for 2 hours, centrifuge at 8000rmp, wash with ethanol, and vacuum dry at 90°C 4 hours.

[0029] (3) Add 20 mL of toluene to the product in step 2, add 2.5 mL of methyltriethoxysilane, and heat to reflux at 70° C. for 10 hours to obtain a supported meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com