Method for preparing metal organic framework film

A technology of metal-organic frameworks and ionic polymers, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the limitations of repeatability, poor binding force between membranes and carriers, and difficulties in preparing dense metal-organic framework membranes and other problems to achieve the effect of eliminating performance differences and improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Synthesis of ZIF-8 membrane on organic carrier tube

[0025] Immerse the ultrafiltration-type polyphenylene biphenyl copolyethersulfone (PPBES) carrier into an aqueous solution of 1 wt.% polystyrene sulfate sodium salt (PSS), keep it at 60°C for 4 hours, take it out, rinse the surface with deionized water, and dry it at room temperature spare;

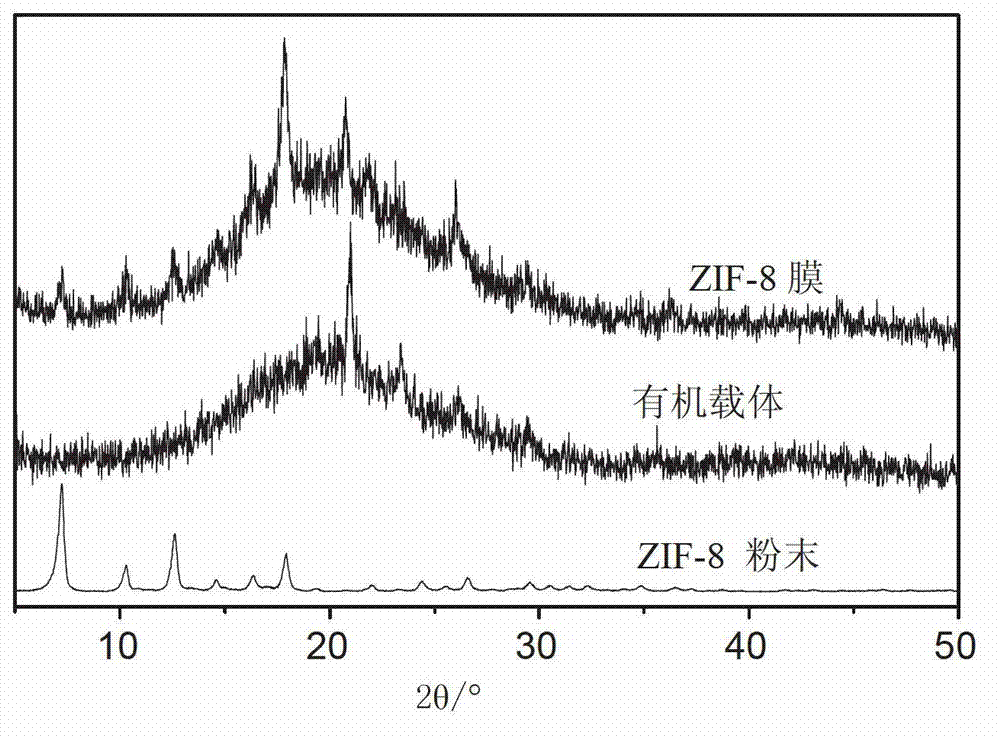

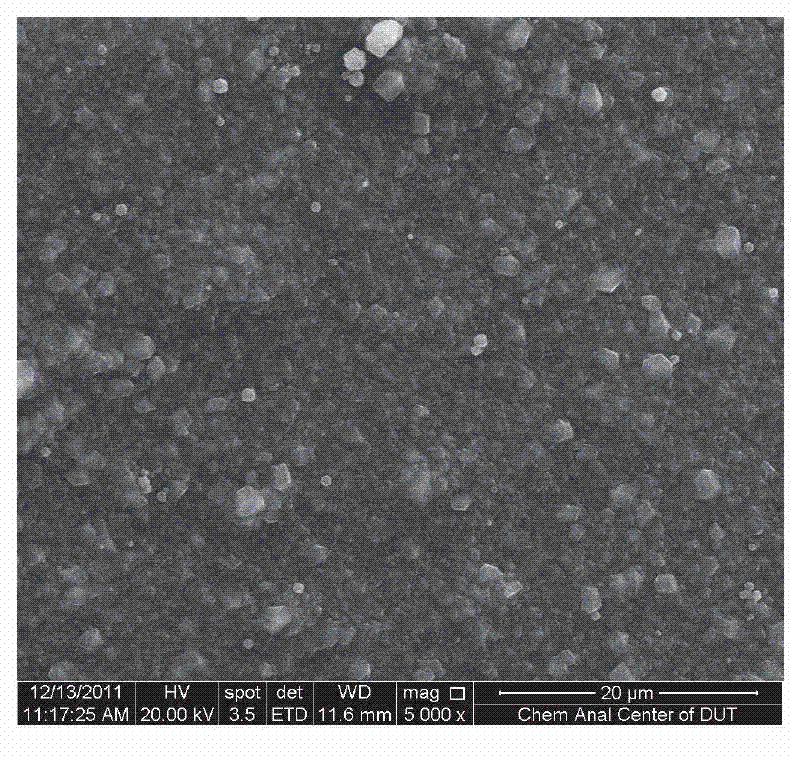

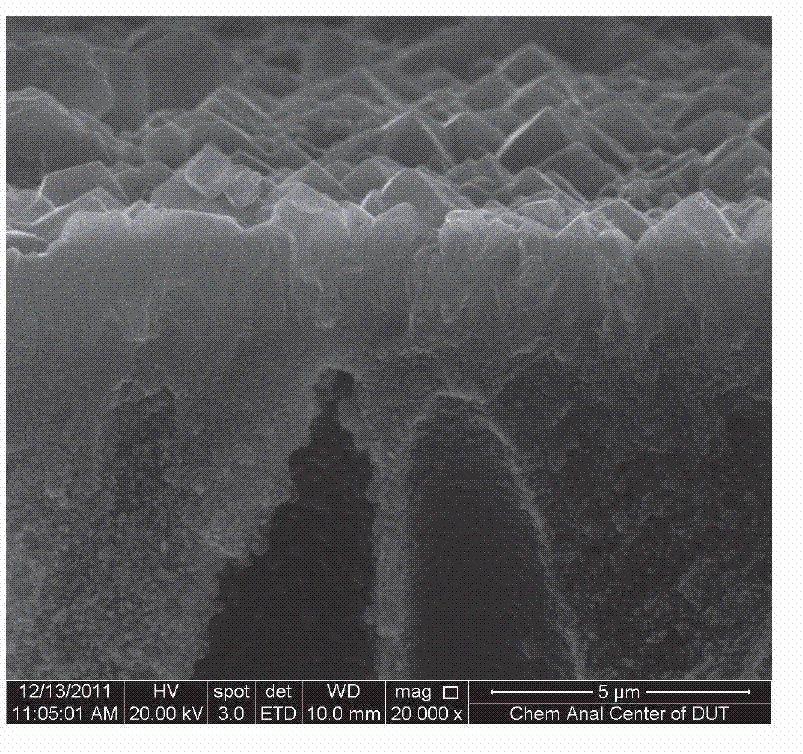

[0026] 0.0825g Zn(NO 3 ) 2 ·6H 2 O and 1.7025g of 2-methylimidazole were dissolved in 5mL and 25mL of water respectively, and the two solutions were heated to 40°C and stirred vigorously, and the 2-methylimidazole solution was quickly added to the zinc nitrate solution. Take the organic carrier treated with polystyrene sulfate sodium salt, put it vertically into the film-forming solution of ZIF-8, and react at 40°C for 6h under stirring condition. The prepared ZIF-8 membrane was rinsed with deionized water and methanol, and dried at room temperature for later use. The resulting ZIF-8 film was confirmed by X-ray di...

Embodiment 2

[0027] Example 2 Synthesis of ZIF-7 film on alumina ceramic tube carrier

[0028] The alumina ceramic carrier was sequentially soaked in an aqueous solution of 1 wt.% polydiallyldimethylammonium chloride (PDDA) and 1 wt.% polystyrene sulfate sodium salt (PSS), and the surface was simply cleaned and dried for later use .

[0029] 1.153g Zn(NO 3 ) 2 ·6H 2 O and 0.781g of benzimidazole were dissolved in 80mL of dimethylformamide (DMF) and then transferred to a polytetrafluoroethylene hydrothermal synthesis kettle. The treated alumina carrier was immersed in the synthesis solution and reacted at 100°C. 24h. After natural cooling, the prepared ZIF-7 membrane was rinsed with DMF and methanol, and dried under a vacuum of 0.1 MPa at 50° C. for use. The obtained ZIF-7 film was confirmed by X-ray diffraction to be a ZIF-8 structure with good crystallinity (such as image 3 shown). Scanning electron micrographs of the ZIF-7 film showed that a uniform and dense ZIF-7 film was forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com