Negative electrode active material for nonaqueous electrolyte secondary battery

A negative electrode active material, non-aqueous electrolyte technology, applied in the field of non-aqueous electrolyte secondary battery negative electrode, non-aqueous electrolyte secondary battery field, can solve the problem of low theoretical discharge capacity, difficult to cope with the increase in power consumption for on-board use Battery use and other issues, to achieve the effect of improved charge-discharge cycle characteristics, good electronic conductivity, and improved oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

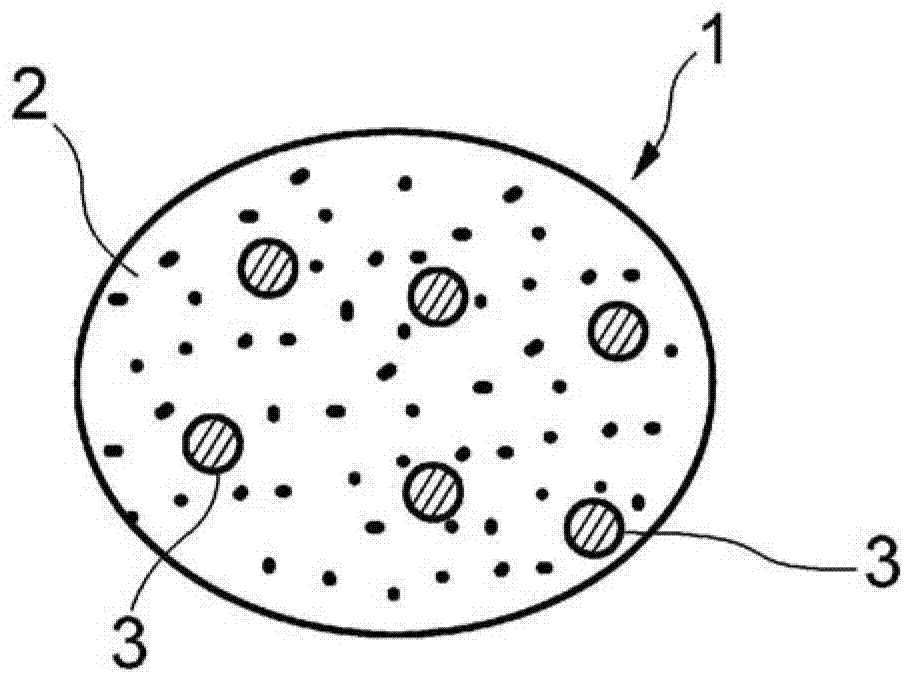

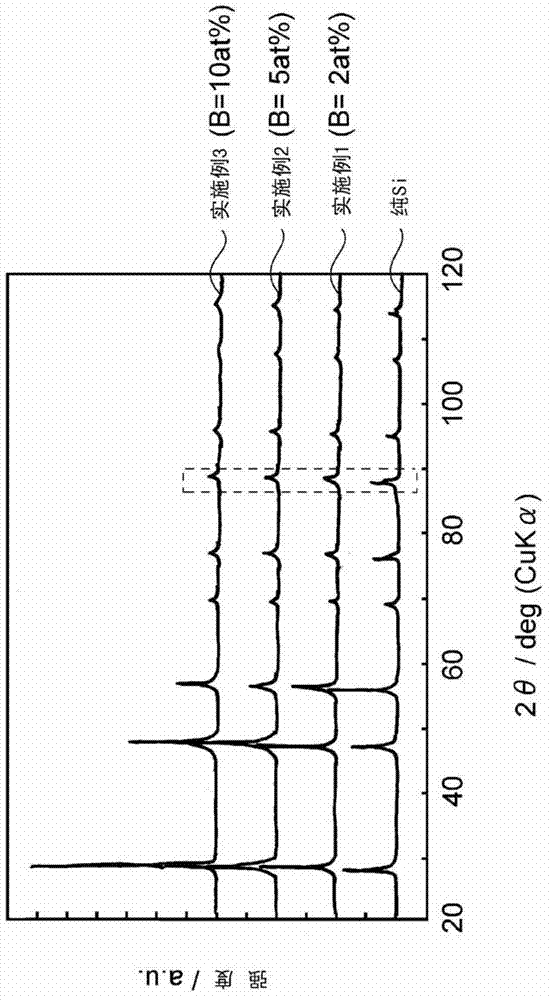

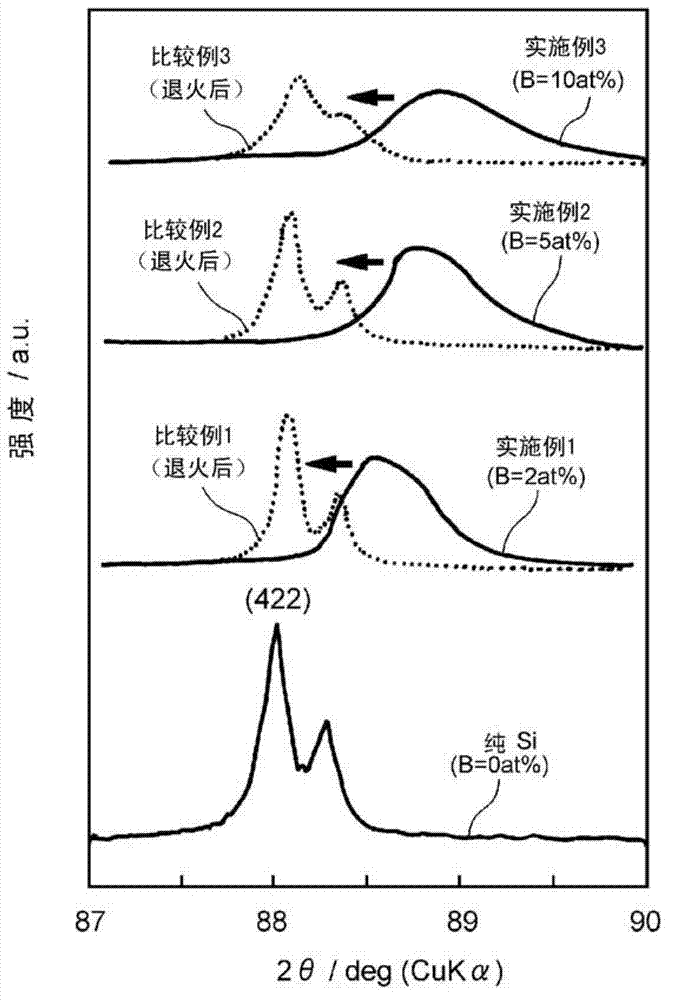

[0068] Using International Publication No. 01 / 081033 pamphlet figure 2 The device described in , carries out the steam explosive atomization method to produce a silicon solid solution with boron in solid solution. The solid solution amount of boron was set as shown in Table 1 below. In the device shown in the figure, the inner diameter of the cylindrical mixing nozzle 2 is set to 2.0 mm. The amount of coolant swirling in the mixing nozzle was set at 100 liters / min. Use room temperature water as the coolant. The mixed melt of silicon and boron was preheated to 1600° C., and was dropped (free-fall) into the mixing nozzle 2 at a time of 13 g. The cooling rate at this time is estimated to be 10 by the above-mentioned estimation method. 6 ~10 8 K / s. The XRD diffraction pattern (ray source: CuKα) of the negative electrode active material composed of the silicon solid solution obtained above is shown in figure 2 middle. The XRD diffraction pattern of pure silicon is also sh...

Embodiment 4

[0072] Except having set the composition of the negative electrode active material to the composition shown in Table 1, it carried out similarly to Examples 1-3, and obtained the negative electrode active material. The negative electrode active material obtained in this way is composed of a mixture in which ferrosilicon alloy is precipitated in a silicon solid solution matrix in which boron is solid-dissolved. Precipitation of ferrosilicon alloy can be confirmed by detecting silicon and iron at the same position in the element distribution of the micro-region of the cross section of the active material particle using EDX. The XRD diffraction pattern of this mixture is shown in Figure 4 (a). In addition, the enlarged XRD diffraction pattern in the range of 2θ=87~90 degrees in the figure is shown in Figure 4 (b). Table 1 shows the degree of shift of the position of the XRD peak of the mixture corresponding to the peak relative to the position of the XRD peak assigned to the (...

Embodiment 5 and 6

[0074] In Example 1, except having used germanium in the amount shown in the following Table 1 instead of boron, it carried out similarly to Example 1, and obtained the negative electrode active material which consists of Si-Ge solid solution. Table 1 shows the degree of shift of the position of the XRD peak of the negative electrode active material corresponding to the position of the XRD peak attributable to the (422) plane of silicon for this solid solution. In addition, the lattice distortion of this mixture was calculated|required using Hall's method. The results are also shown in Table 1. In Table 1, regarding the shift value of the position of the XRD peak, a positive number represents a shift to a high angle side, and a negative number represents a shift to a low angle side.

[0075] Table 1

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com