Hot-rolled steel sheet manufacturing method and manufacturing device

一种热轧钢板、制造方法的技术,应用在工件加热装置、金属轧制、制造工具等方向,能够解决精轧速度低速化、难以应对、加速轧制精轧速度变化等问题,达到削减设备成本及能量成本、提高品质、降低设备建造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

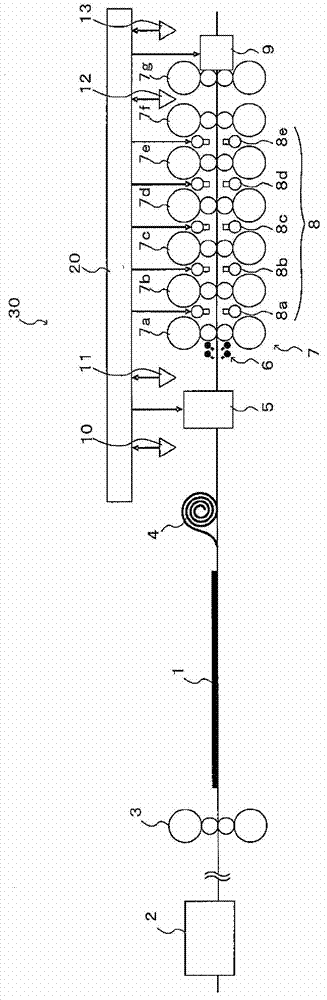

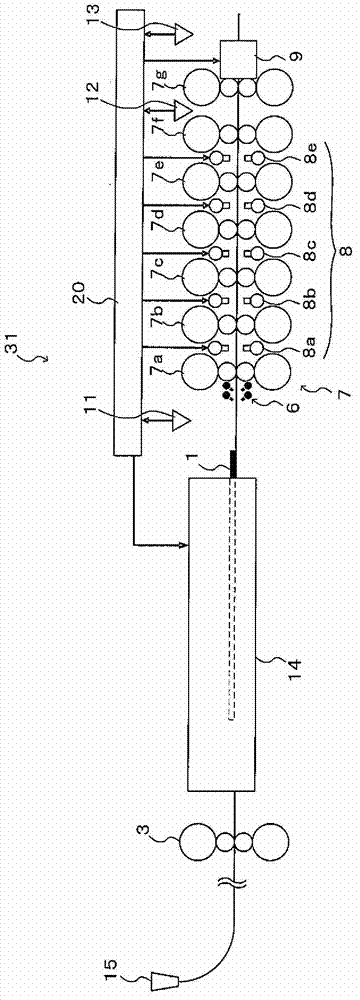

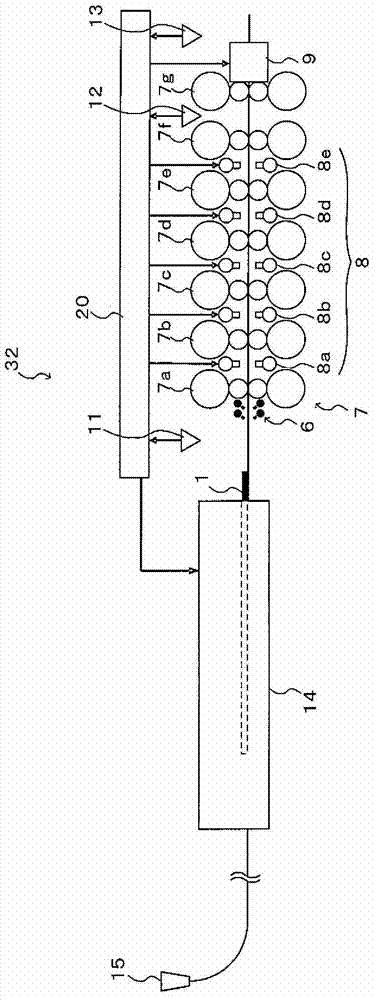

[0074] The production conditions of the hot-rolled steel sheet of the present invention are shown below. The following simulation experiments were carried out, namely, using figure 1 The manufacturing device 30 shown, figure 2 The manufacturing device 31 shown and image 3 The manufacturing device 32 shown is used to manufacture high-strength steel sheets (Examples 1-3). The specifications of the steel sheets are product thickness 2mm, product width 1000mm, product weight 15t, and it contains C: 0.10% by mass, Mn: 1.00% by mass % and Si: 0.05% by mass.

[0075]Regarding the finishing rolling conditions, in the finishing mill row 7 of seven rolling mills, the interval between the rolling mills was 5.5 m, and the reduction rate of the three rolling mills 7e to 7g on the rear stage side was 30%. In addition, the rolling time interval between the final rolling stand 7g of the finishing rolling mill row 7 and the rolling stand 7f of the one rolling stand upstream of the final r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com