Deep hole staggered back contact solar battery structure and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of affecting photoelectric conversion efficiency, large series resistance of batteries, and inability to generate electricity, so as to shorten the diffusion distance, Effect of improving conversion efficiency and reducing recombination loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

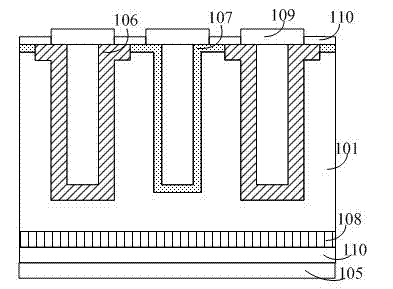

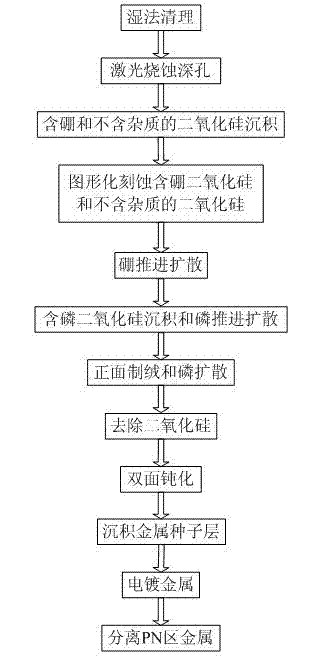

[0022] Example: choose N-type silicon wafers for silicon substrates (P-type monocrystalline silicon wafers and N-type or P-type polycrystalline silicon wafers can also be used), crystal orientation, resistivity 1-20 Ω cm, silicon The slice thickness is 200um, and the deep hole depth is 180um. The specific process steps are as follows (see figure 1 , figure 2 and image 3 ):

[0023] (1) Wet cleaning: the silicon substrate 101 is wet-processed to facilitate the cleaning of the rear surface 102 and the front surface 103 and to etch away rough particles on the surface.

[0024] (2) Laser ablation of deep holes: a laser scanner is used to ablate the rear surface 102 of the silicon substrate 101 to form deep holes 104. The size of the deep holes is related to the thickness of the silicon substrate, and the thickness of the silicon substrate 101) is preferably 200um. The depth of the hole 104 is 180um.

[0025] (3) Boron-containing and impurity-free silicon dioxide deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com