Hydraulic control cycling switch

A technology for controlling circulation and switching, which is applied in wellbore/well components, earthwork drilling, wellbore flushing, etc. It can solve problems such as troublesome workover operations, waste of wellwashing fluid, and polluted oil layers, and achieves simple structure and convenient use , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation and working process of the present invention will be described in detail below in conjunction with the accompanying drawings.

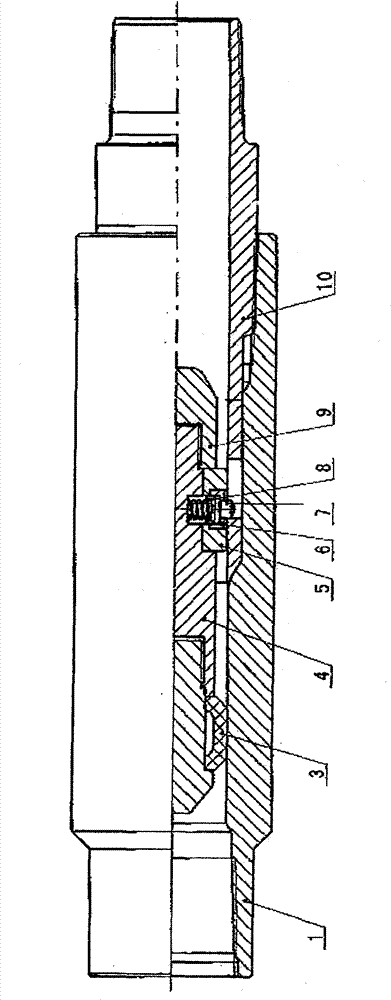

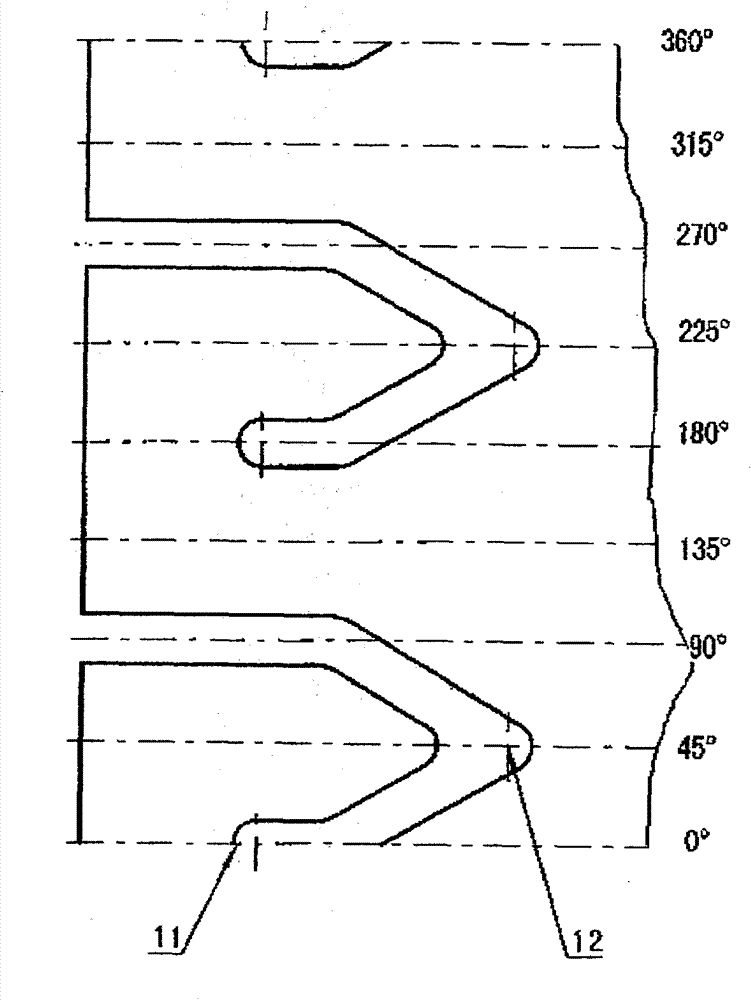

[0016] Such as figure 1 , figure 2 Shown:

[0017] A hydraulic control cycle switch is mainly composed of an upper joint 1, an upper guide body 2, a rubber 3, a connecting body 4, a fixing ring 5, a nut 6 for the fixing ring, a track pin 7, a spring 8, a lower guide body 9, and a lower joint 10 composition.

[0018] The specific implementation is as follows:

[0019] First put the fixed ring 5 on the connecting body 6 and rotate it so that the spring holes on the two parts correspond, put the spring 8 in the spring hole and install the track pin 7, and then connect the fixed ring nut 6 to the fixed On the ring 5, the lower guide body 9 is threadedly connected to the connecting body 4, the rubber 3 is set on the outer cylindrical surface of the upper guiding body 2, and then the upper guiding body 2 and the connecting bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com