Rack structure and application thereof

A gear structure and rack technology, applied in the field of deceleration transmission structure, can solve the problems of scrapped gears, easy wear, short service life of the substrate, etc., and achieve the effect of ensuring regular production, ensuring service life, and rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 5

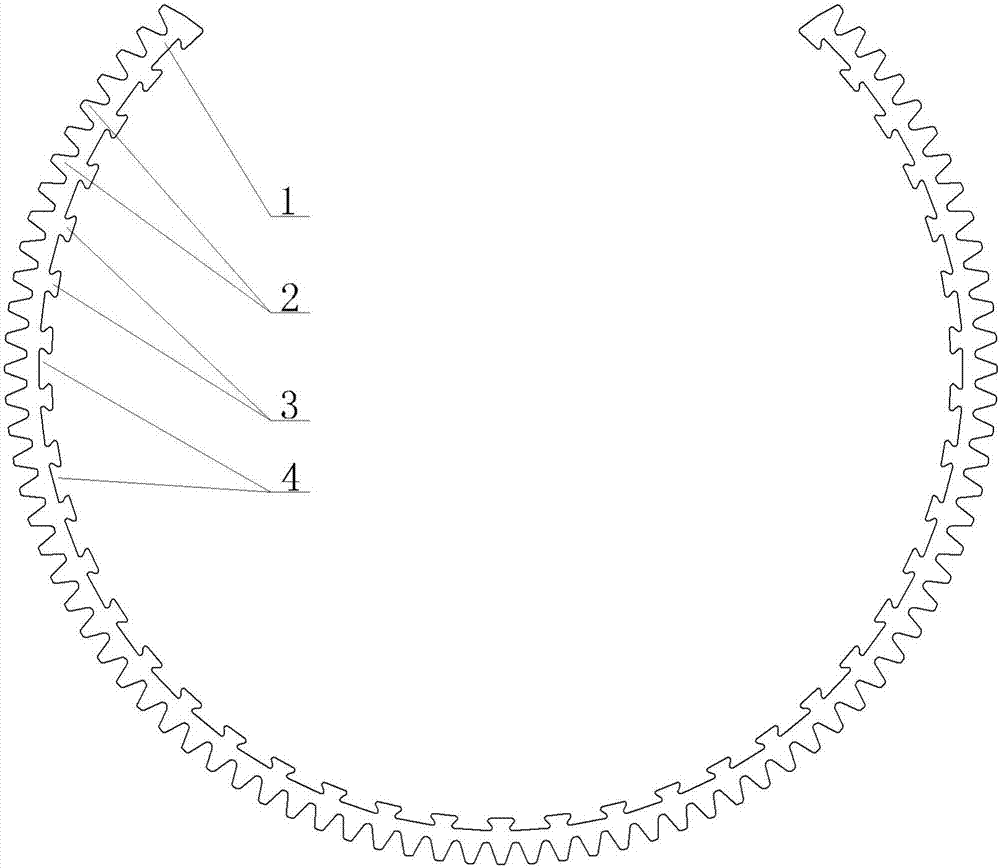

[0039] Specific embodiment five, see Figure 5 : When the rack structure of the arc carrier is not provided with the first air hole structure 7, the outer ring surface of the rack body 8 is covered with a positioning groove 9 corresponding to the radian, and the protrusion 3 and the positioning groove 9 of the rack body 8 are embedded tightly matched arrangement.

specific Embodiment 6

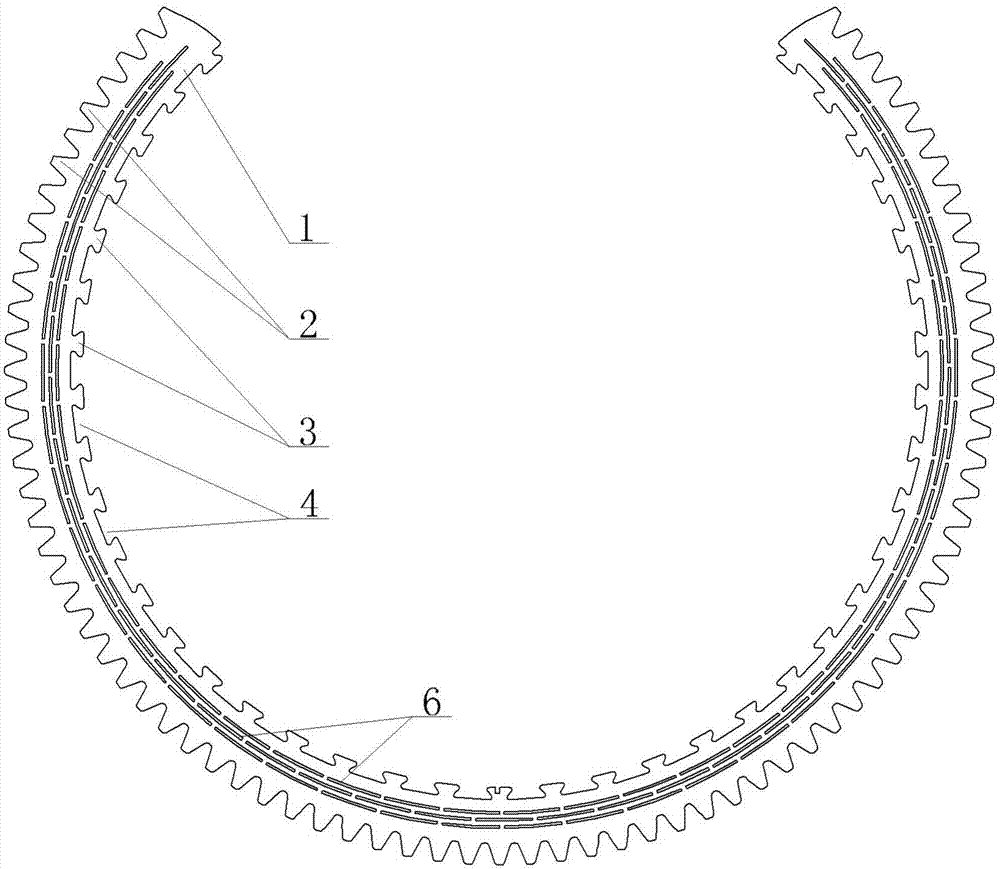

[0040] Concrete embodiment six, see Image 6 : When the rack structure of the arc carrier is provided with the first air hole structure 7, the outer ring surface of the rack body 8 is covered with a positioning groove 9 corresponding to the radian, and the embedding protrusion 3 and the positioning groove 9 of the rack body 8 Closely matched arrangement.

specific Embodiment 7

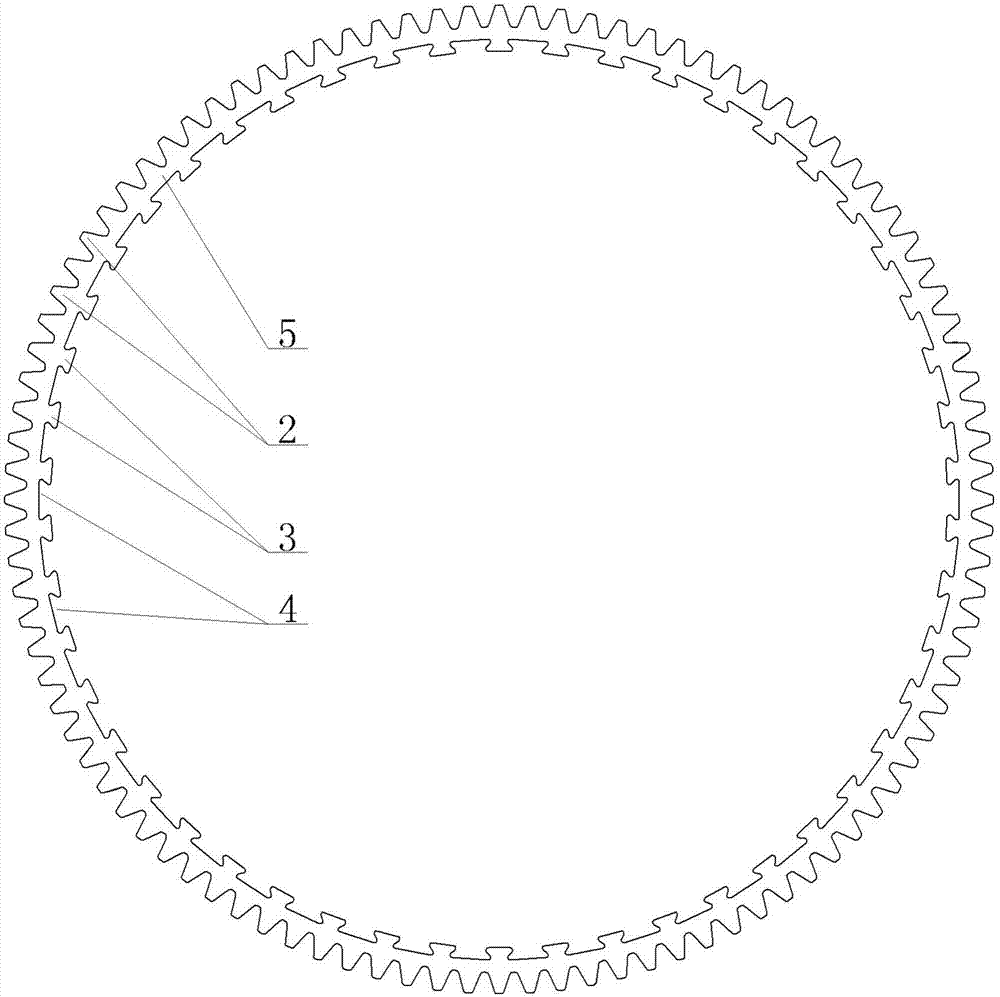

[0041] Specific embodiment seven, see Figure 7 : When the rack structure is not provided with the first air hole structure, the inner ring part of the positioning groove of the rack body 8 is provided with a plurality of mutually discontinuous second air hole structures 10 along the circumferential direction, and the second air hole structures 10 run through the rack body Arranged in the width direction of the rack body 8, the outer ring surface of the rack body 8 is covered with a positioning groove 9 corresponding to the radian, and the embedded protrusion 3 and the positioning groove 9 of the rack body 8 are arranged in close fit;

[0042] The second pore structure 10 is in the shape of a circle, a circle, a fan, an arc, a rectangle or a rectangle;

[0043] The overall radial compression of the second pore structure 10 is 0.1mm˜0.3mm.

[0044] In the specific embodiment, the overall radial compression of the first air hole structure 6 and the second air hole structure 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com