Bridge bulk mass concrete skewback structure

A technology of large-volume concrete and plain concrete, which is applied in bridges, bridge construction, bridge parts, etc., can solve the problems of potential safety hazards in the operation of bridges, waste of masonry materials, and easy formation of cracks, etc., to reduce the hydration heat effect, Reduce the probability of crack formation and avoid the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

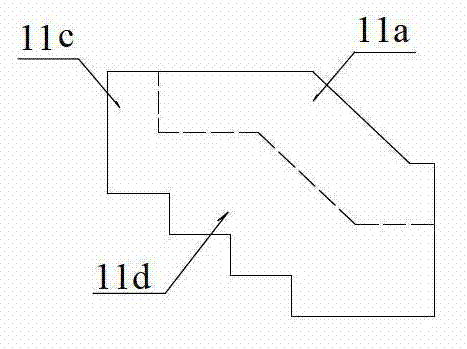

[0018] refer to figure 1 and figure 2 , the large-volume concrete abutment structure of the bridge of the present invention includes supporting and fixedly connecting the abutment 10 of the junction pier 20 and the arch ring 30. It is formed with the upper reinforced concrete pouring body 12. The double dotted line in the figure is the dividing line between the lower plain concrete pouring body 11 and the upper reinforced concrete pouring body 12. The junction pier 20 and the arch ring 30 are poured on the upper reinforced concrete pouring body 12 superior. The abutment is divided into upper and lower parts, the force is reasonable, and the force transmission is clear. This processing method that suits the characteristics of the force can make full use of the bearing capacity of the rock mass and is more conducive to load transmission.

[0019] refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com