Fancy yarn and method of making the same

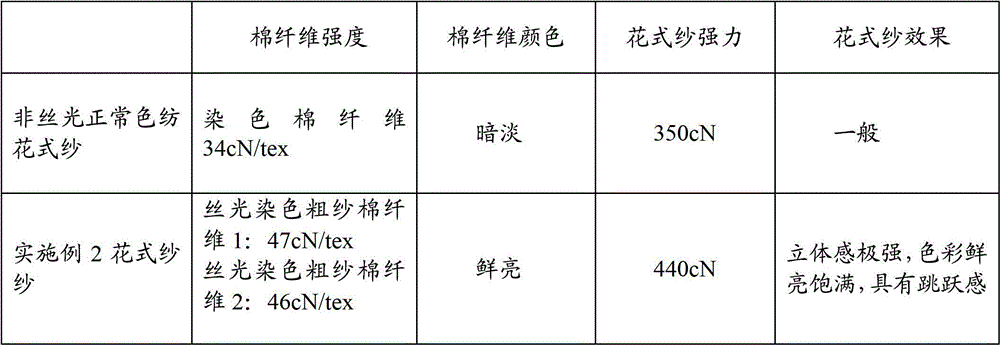

A technology of fancy yarn and roving, applied in the direction of yarn, dyeing method, mercerizing of yarn/thread/filament, etc., can solve the problems of strong damage of cotton fiber, large damage of cotton fiber, complicated process, etc., and achieve the improvement of fiber strength, The three-dimensional effect of the yarn is strong, and the effect of expanding the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

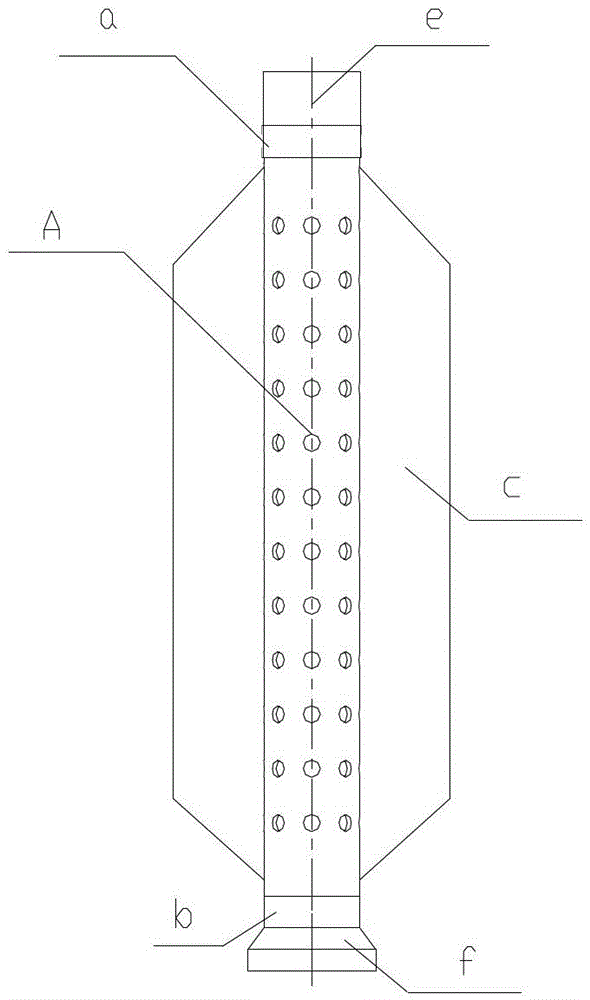

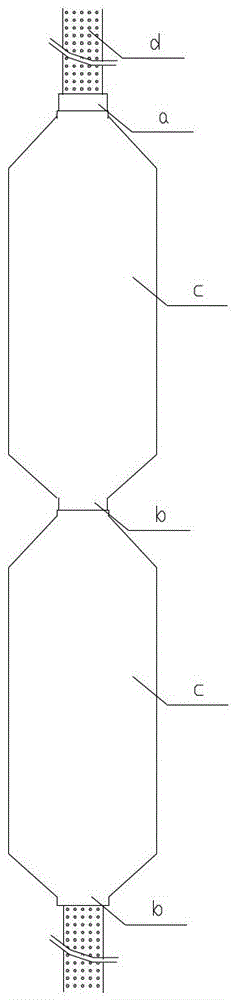

[0027] Example 1 Roving bobbin used in fancy yarn manufacturing process

[0028] refer to Figure 1-2 The roving bobbin A used in the manufacturing method of the fancy yarn of the present invention comprises a bobbin e matched with the spindle bar of the roving frame, a bobbin body with dyed yarn holes distributed on the surface and a bobbin f matched with the spindle seat of the roving frame , wherein the pipe head e and the pipe body head end a are threadedly connected, the pipe body head end a at the joint is an external thread and the pipe head e is an internal thread; the pipe body bottom b and the pipe bottom f are threadedly connected, and the joint The bottom b of the tube body is internally threaded and the bottom f of the tube is externally threaded. The head end a of the pipe body and the bottom end b of the pipe body can be nested with each other, the head end a of the pipe body is a male head, the bottom end b of the pipe body is a female head, and the outer diam...

Embodiment 2

[0030] Embodiment 2 utilizes the bobbin of embodiment 1 to make fancy yarn

[0031] Including the following processes: roving preparation - roving mercerizing - roving dyeing - roving drying - spinning.

[0032] S 1 : prepare roving

[0033] The roving bobbin A with the dyed yarn hole is placed on the roving frame, and the roving sliver with a British twist coefficient of 2.2 is wound onto the bobbin of the roving bobbin to make a roving bobbin. The fiber main body length of the roving sliver is 37mm, and the roving sliver The winding thickness of the roving is 3cm, and the winding density of the roving strip is 0.4g / cm 3 ;

[0034] In this example, the roving stock is cotton.

[0035] S 2 : roving mercerized

[0036] Remove the tube head and tube bottom of the roving tube, place the roving tube on the dyeing rod d and put it in the dyeing vat, inject 220g / L caustic soda solution, treat at 30°C for 20 minutes, the lye circulates from the inside to the outside, and then d...

Embodiment 3

[0047] Embodiment 3 Utilize the bobbin of embodiment 1 to make fancy yarn

[0048] Including the following processes: roving preparation - roving mercerizing - roving dyeing - roving drying - spinning.

[0049] S 1 : prepare roving

[0050] The roving bobbin A with the dyed yarn hole is placed on the roving frame, and the roving sliver with a British twist coefficient of 2.0 is wound onto the bobbin of the roving bobbin to make a roving bobbin. The fiber main body length of the roving sliver is 37mm, and the roving sliver The winding thickness is 1cm, and the winding density of the roving sliver is 0.35g / cm 3 ;

[0051] In this example, the roving stock is cotton.

[0052] S 2 : roving mercerized

[0053] Remove the tube head and tube bottom of the roving bobbin, place the roving bobbin on the dyeing rod d and put it in the dyeing vat, inject 140g / L potassium hydroxide solution, treat at 20°C for 30 minutes, and circulate the lye from inside to outside. Then discharge t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com