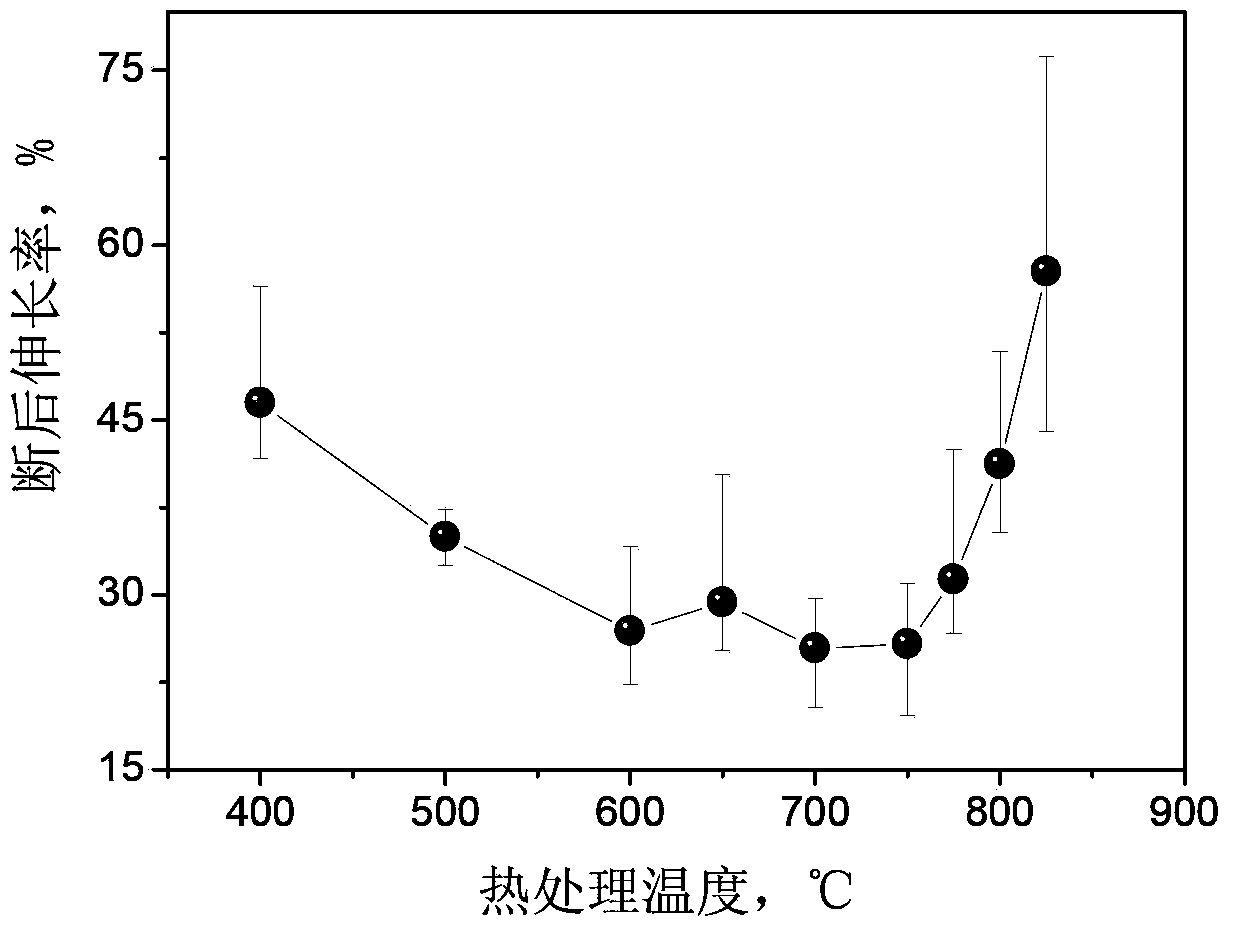

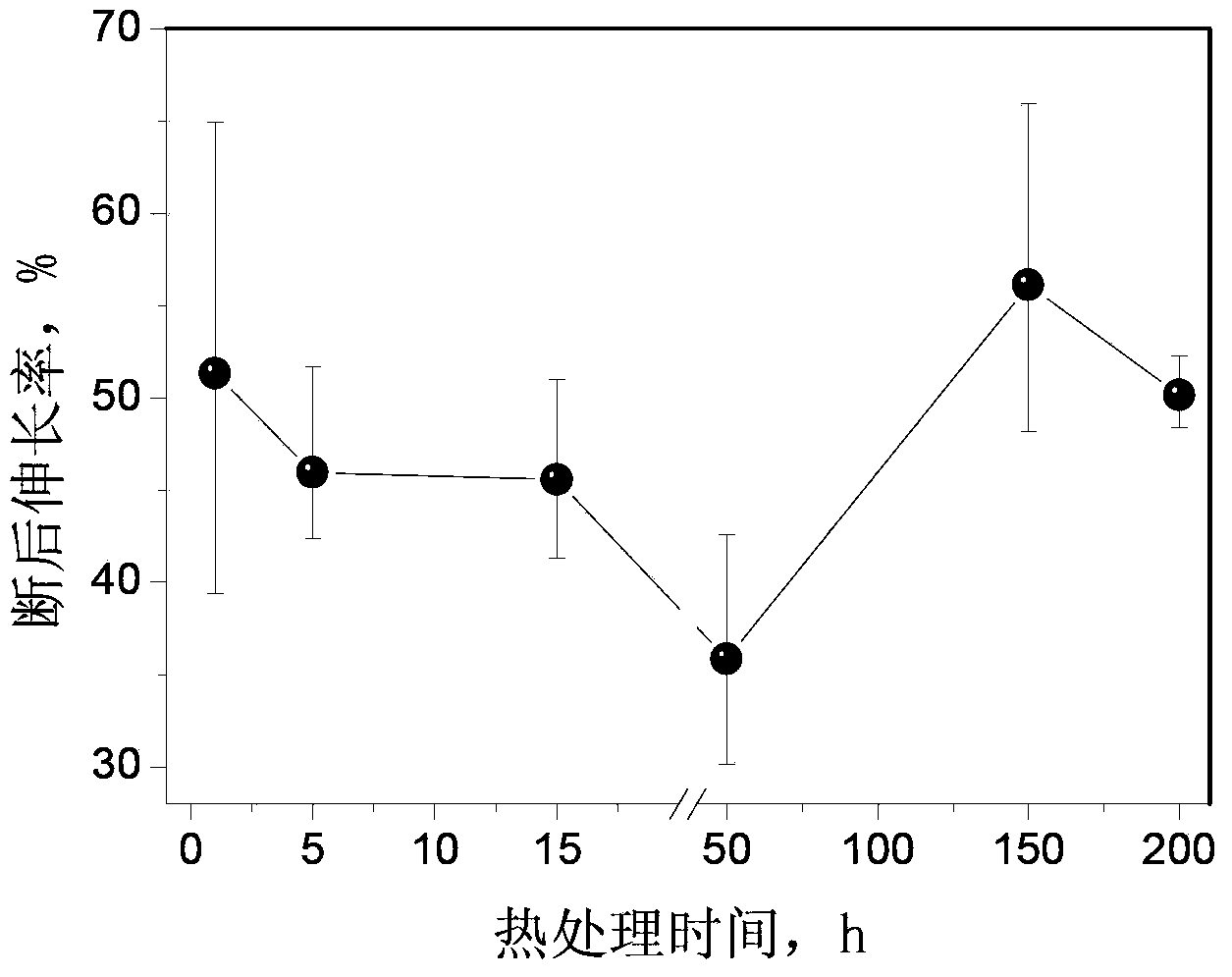

Method for preparing high-tensile-ductility Ni (Bi) alloy

A tensile plasticity and alloy technology, which is applied in the testing and heat treatment process, the smelting and processing of Ni alloys, and the preparation of high tensile plasticity Ni alloys, which can solve the problems of low tensile plasticity of Ni(Bi) alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

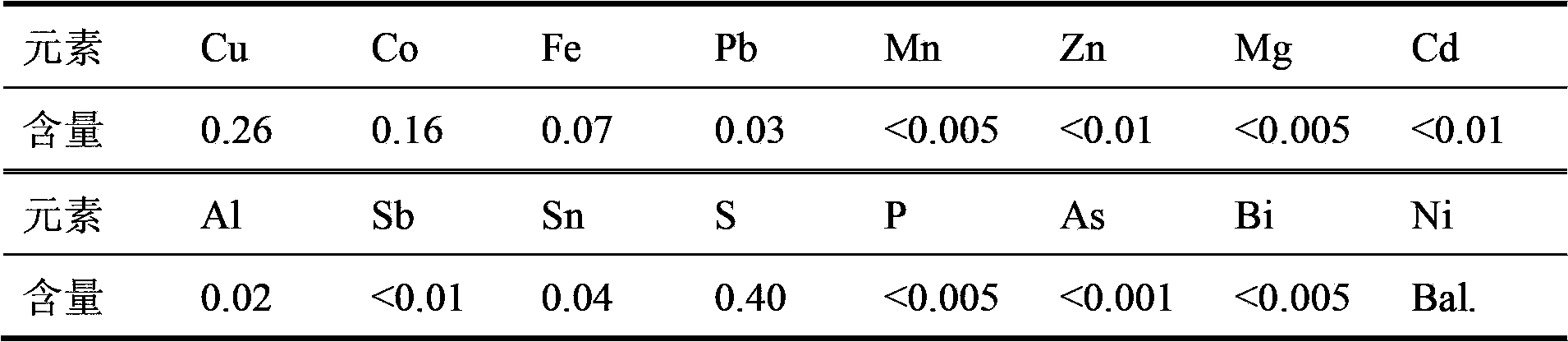

[0045] (1) High-purity electrolytic Ni plate is used as raw material, the thickness of Ni plate is between 2 and 3 mm, and the composition is shown in Table 1.

[0046] Table 1 Chemical composition of high-purity Ni (wt ppm)

[0047]

[0048] (2) The high-purity electrolytic Ni plate was cut into particles by mechanical shears, and then the particles were ultrasonically cleaned in 4 mol / L hydrochloric acid solution for 5 minutes, and then ultrasonically cleaned in distilled water for 5 minutes.

[0049] (3) The cleaned particles are dried in a constant temperature drying oven at a temperature of 120° C. for 10 hours.

[0050] (4) Mix high-purity Ni particles and high-purity Bi according to the molar ratio of Ni:Bi=99.9:0.1, and put them into a vacuum induction melting furnace.

[0051] (5) Pump the vacuum degree of the vacuum induction melting rate to 5×10 -3 Pa.

[0052] (6) Slowly raise the melting temperature to 1530° C. and keep it at 1530° C. for 5 minutes.

[0053...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com