Composite functional nanosphere with polymer wrapping hydrophobic nano grains and preparation method of composite functional nanosphere

A nanoparticle and composite function technology, which is applied in the field of composite functional nanospheres coated with hydrophobic nanoparticles by polymers and the preparation thereof, can solve the problems of limited application range and the like, and achieves strong hydrophilicity, low synthesis cost, and particle size distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

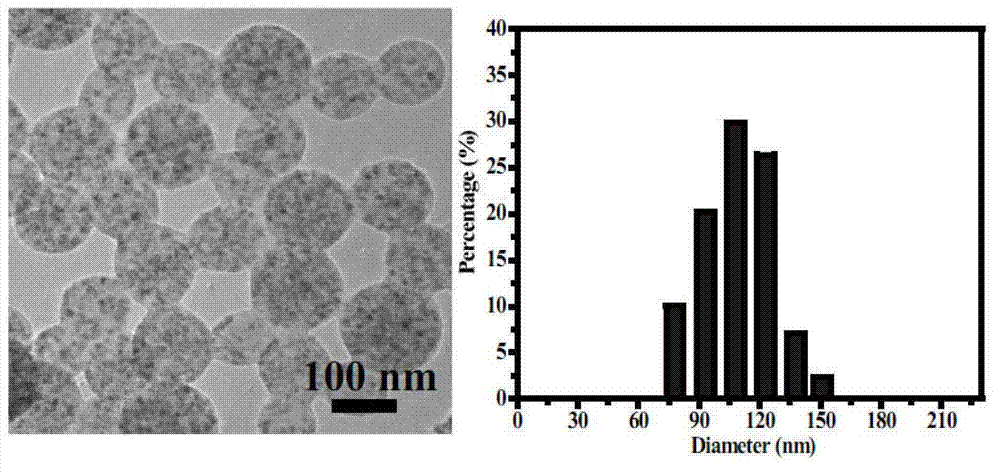

Embodiment 1

[0031] a. Oil phase ZnS:Mn chelated with oleic acid 2+ Nanoparticles (about 7 nm in particle size) were uniformly dispersed in 750 μl of chloroform to obtain a nanoparticle solution, wherein the nanoparticle was 2 mmol;

[0032] b. Add 0.01g of sodium dodecylsulfonate to 12ml of deionized water, sonicate until it is completely dissolved, then add the nanoparticle solution obtained in step a of 750-1, and ultrasonicate for 3 minutes in an ultrasonic cell disruptor to obtain a nanoparticle Particle emulsion, then rotary steamed at 60°C for 10 minutes under vacuum;

[0033] c. Add 0.0125g of sodium dodecylsulfonate into 10ml of deionized water, sonicate until it is completely dissolved, then add 0.354ml of mixed monomer and 0.07ml of ethylene glycol dimethacrylate, and sonicate in an ultrasonic cell disruptor for 3 Minutes; The mixed monomer is styrene and methacrylic acid with a volume ratio of 350:4;

[0034] d. Mix the products obtained in steps b and c, add 0.01g of azobi...

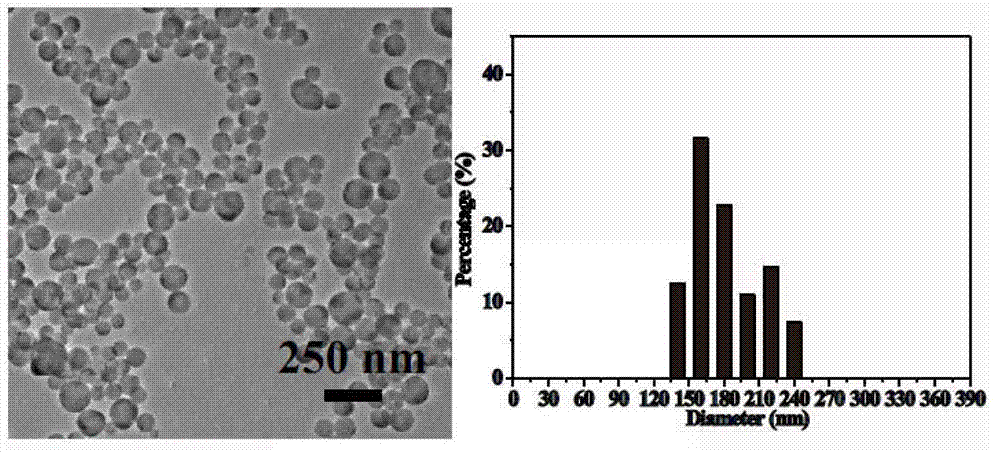

Embodiment 2

[0036] a. Oil phase Fe chelated with oleic acid 3 o 4 Nanoparticles (about 6nm in diameter) are uniformly dispersed in 1000 μl of chloroform to obtain a nanoparticle solution, wherein the nanoparticle is 2 mmol;

[0037] b. Add 0.01 g of sodium dodecylsulfonate to 12 ml of deionized water, sonicate until it is completely dissolved, then add 750 μl of the nanoparticle solution obtained in step a, and sonicate for 3 minutes in an ultrasonic cell disruptor to obtain a nanoparticle emulsion , and then rotary steamed at 60°C for 10 minutes under vacuum;

[0038] c. Add 0.0125g of sodium dodecylsulfonate to 10ml of deionized water, sonicate until it is completely dissolved, then add 0.7ml of monomeric styrene, and sonicate in an ultrasonic cell disruptor for 3 minutes;

[0039] d. Mix the products obtained in steps b and c, add 0.01g of azobisisobutyrocyanide, and react at 80°C for 10 hours; after cooling, centrifuge at 6000r / min for 3 minutes, dissolve the obtained solid with w...

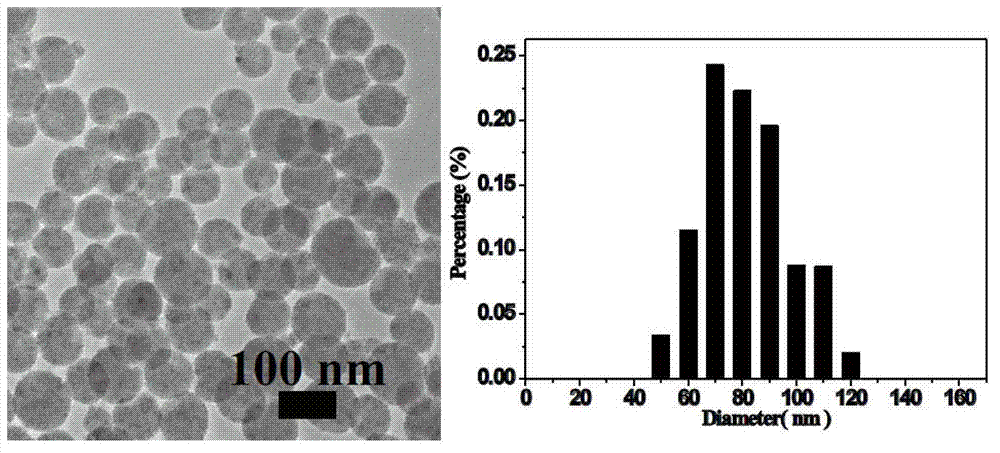

Embodiment 3

[0041] a. Oil phase Fe chelated with oleic acid 3 o 4 Nanoparticles (about 6nm in diameter) were uniformly dispersed in 1500 μl of chloroform to obtain a nanoparticle solution, wherein the nanoparticle was 3 mmol;

[0042] b. Add 0.02 g of sodium dodecylsulfonate to 12 ml of deionized water, sonicate until it is completely dissolved, then add 1500 μl of the nanoparticle solution obtained in step a, and sonicate for 3 minutes in an ultrasonic cell disruptor to obtain a nanoparticle emulsion , and then rotary steamed at 60°C for 10 minutes under vacuum;

[0043] c. Add 0.01g of sodium dodecylsulfonate into 10ml of deionized water, sonicate until it is completely dissolved, then add 0.3ml of mixed monomers and 0.05ml of ethylene glycol dimethacrylate, and sonicate in an ultrasonic cell disruptor for 3 Minutes; the mixed monomer is styrene and hydroxyethyl methacrylate with a volume ratio of 2:1;

[0044] d. Mix the products obtained in steps b and c, add 0.01g of azobisisobu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com