Sintering method for improving mechanical strength of tantalum wire

A sintering method and technology of mechanical strength, applied in the field of metal smelting, can solve problems such as affecting use, and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

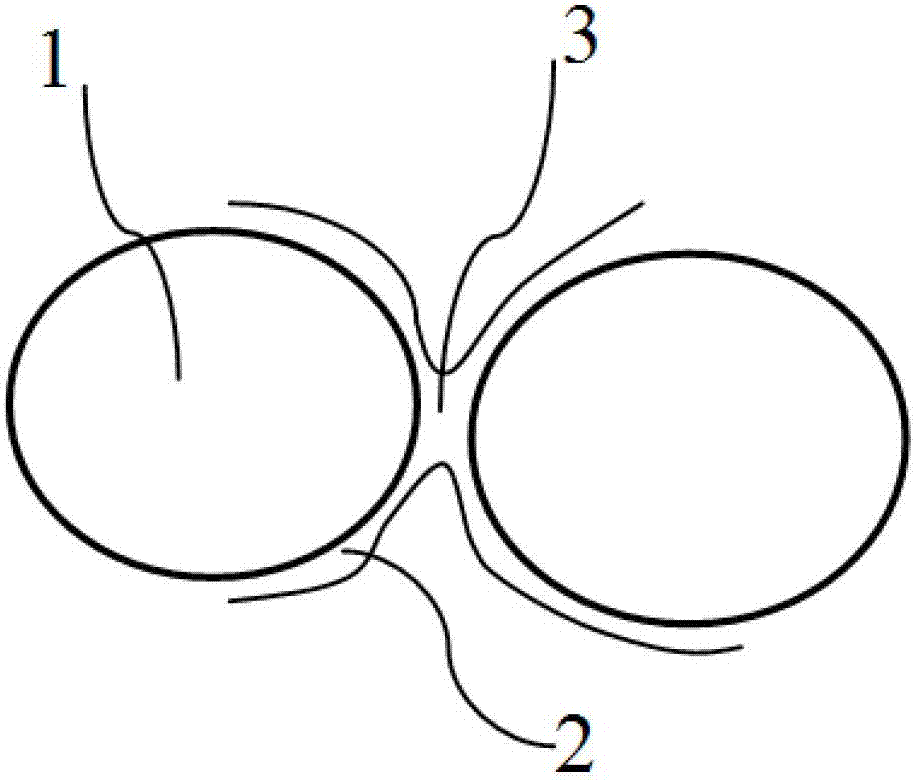

Image

Examples

Embodiment Construction

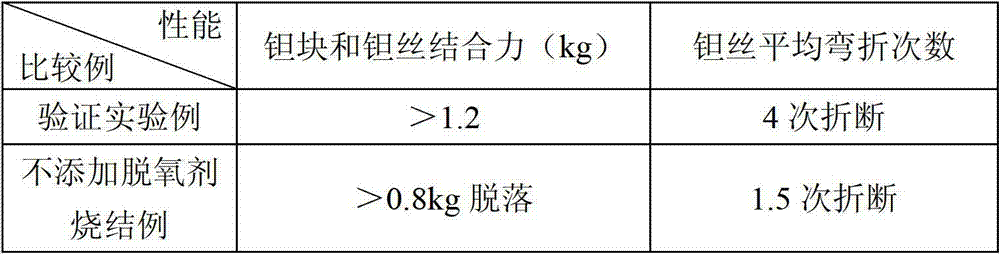

[0009] The idea of the present invention to solve the technical problem is to sinter the metal which has a low melting point and which itself or its oxide is easy to react with water or acid as a deoxidizer and the pressed tantalum wire in a vacuum state, so that the tantalum wire is oxidized Partial deoxidation, after the deoxidation is completed, continue to raise the temperature in a vacuum state to sinter the tantalum wire and crystallize the tantalum powder, thereby improving the mechanical strength of the tantalum wire.

[0010] The technical solution of the present invention is specifically realized in this way. Taking active metal magnesium as a deoxidizer as an example, first put magnesium and a container for sintering tantalum wire, such as a tantalum crucible, into a vacuum coating device, and heat up in a vacuum state to vaporize the magnesium After cooling, the magnesium forms a layer of magnesium film on the surface of the tantalum crucible; then the pressed tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com