Filling mould module and construction method thereof

A construction method and filling mold technology, which can be applied to building components, walls, floors, etc., can solve the problems of volume limitation, reduce concrete performance, increase cost, etc., and achieve the effect of facilitating factory production, reducing panel costs, and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

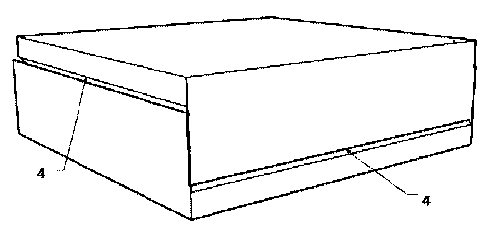

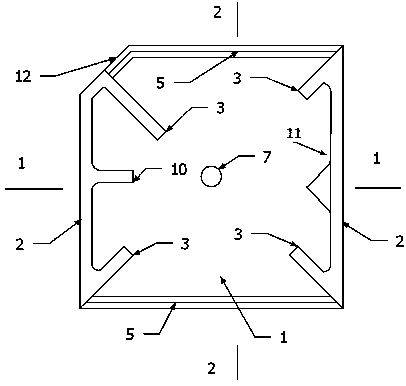

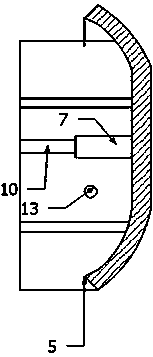

[0043] Embodiment 1: as Figure 2 ~ Figure 4 The filling mold module shown includes a panel 1, a side panel 2, and a docking panel 3. The docking panel and the side panel are perpendicular to the panel, and the angle between the connecting panel and the side panel is 45 degrees. The two modules face each other to form a curing joint. The free edge of side plate 2 is the slope of 45 degrees inwards. The two free edges of the panel 1 are provided with convex ribs 5 with an outer slope of 45 degrees. The inner surface of the panel 1 is concave, and the outer surface is convex. The inner surface of the panel 1 is connected with a pillar 7 in the center, and the height of the pillar 7 is half of the height of the side plate 2 . The inner surface of the panel 1 and the space between the side panels 2 are filled with thermal insulation materials, and the filling height is no more than half of the height of the side panels 2 . There is a stiffening rib 10 perpendicular to the panel ...

Embodiment 2

[0045] Embodiment 2: as Figure 2 ~ Figure 4 The filling mold module shown includes a panel 1, a side panel 2, and a docking panel 3. The docking panel and the side panel are perpendicular to the panel, and the angle between the connecting panel and the side panel is 45 degrees. The two modules face each other to form a curing joint. The free edge of side plate 2 is the slope of 45 degrees inwards. The two free edges of the panel 1 are provided with convex ribs 5 with an outer slope of 45 degrees. The inner surface of the panel 1 is concave, and the outer surface is convex. The inner surface of the panel 1 is connected with a pillar 7 in the center, and the height of the pillar 7 is half of the height of the side plate 2 . The inner surface of the panel 1 and the space between the side panels 2 are filled with thermal insulation materials, and the filling height is no more than half of the height of the side panels 2 . There is a stiffening rib 10 perpendicular to the panel ...

Embodiment 3

[0047] Embodiment 3: as Figure 5 ~ Figure 6 The filling mold module shown includes panel 1, side panel 2, butt panel 3, the butt panel and the side panel are perpendicular to the panel, the angle between the panel and the side panel is 45 degrees, and the two modules are oppositely butted to form a curing joint, the side panel The free edge of 2 is an inward 45-degree slope. The two free edges of the panel 1 are provided with convex ribs 5 with an outer slope of 45 degrees. A transverse supporting rib 9 perpendicular to the side plate 2 is connected between the inner surface of the panel 1 and the side plate 2 , and its height is half of the height of the side plate 2 . The inner surface of the panel 1 is connected with a vertical support rib 8 parallel to the side plate 2 , and its height is half of the height of the side plate 2 . The inner surface of the panel 1 and the space between the side plates 2 are filled with thermal insulation materials, and the filling height m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com