Material for preparing turbine rotor of pressurizer and method for preparing turbine rotor by material

A technology of turbine rotor and supercharger, applied in mechanical equipment, machine/engine, blade supporting elements, etc., can solve the problems of unstable service environment performance, structural evolution damage, low service life, etc., to shorten the response time, Low price and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

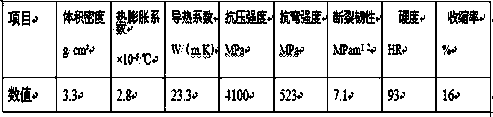

Embodiment 1

[0032] A material for preparing a supercharger ceramic turbine rotor, comprising the following components by weight: 85 parts of silicon nitride powder, nitrogen

[0033] 5 parts of boron nanotube powder, 2 parts of metal aluminum powder, 3 parts of silicon powder, 5 parts of zirconia powder.

[0034] The method for preparing a turbine rotor using the material includes the following steps:

[0035] (1) Raw material preparation: Weigh 85 parts of silicon nitride powder, 5 parts of boron nitride nanotube powder, 2 parts of metal aluminum powder, 3 parts of silicon powder, and 5 parts of zirconia powder by weight to form raw materials.

[0036] (2) Paste preparation: add the raw materials obtained in step (1) to the silica sol in a weight ratio of 1:1.5 into a liftable forced mixer for mixing, at a mixing speed of 60 r / min, and after stirring for 50 minutes, add 3% of the raw material weight of yttrium trioxide sintering aid, while adding 14% of the raw material weight of distilled water...

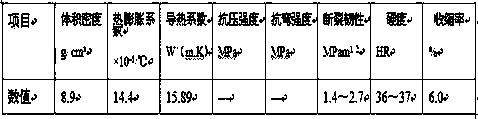

Embodiment 2

[0044] A material for preparing a supercharger ceramic turbine rotor, comprising the following components by weight: 87 parts of silicon nitride powder, nitrogen

[0045] 3 parts of boron nanotube powder, 3 parts of metal aluminum powder, 4 parts of silicon powder, 3 parts of zirconia powder.

[0046] The method for preparing a turbine rotor using the material includes the following steps:

[0047] (1) Raw material preparation: Weigh 87 parts of silicon nitride powder, 3 parts of boron nitride nanotube powder, 3 parts of metal aluminum powder, 4 parts of silicon powder, and 3 parts of zirconia powder by weight to form raw materials.

[0048] (2) Paste preparation: add the raw materials obtained in step (1) to the silica sol in a weight ratio of 1:1.5 to a liftable forced mixer for mixing, stirring at a speed of 55r / min, after mixing for 60 minutes, add the raw materials 2% by weight of yttrium trioxide sintering aid, while adding 13% by weight of raw material, distilled water, continu...

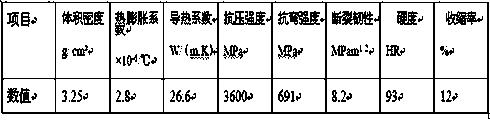

Embodiment 3

[0056] A material for preparing a supercharger ceramic turbine rotor, comprising the following components by weight: 90 parts of silicon nitride powder, nitrogen

[0057] 1 part of boron nanotube powder, 2 parts of metal aluminum powder, 2 parts of silicon powder, 5 parts of zirconia powder.

[0058] The method for preparing a turbine rotor using the material includes the following steps:

[0059] (1) Raw material preparation: Weigh 90 parts of silicon nitride powder, 1 part of boron nitride nanotube powder, 2 parts of metal aluminum powder, 2 parts of silicon powder and 5 parts of zirconia powder by weight to form the raw materials.

[0060] (2) Paste preparation: Add the raw materials obtained in step (1) to the silica sol in a weight ratio of 1:1.5 into the liftable forced mixer for mixing, stirring at 65r / min, after stirring for 55 minutes, add the raw materials 4% by weight of yttrium trioxide sintering aid, while adding 15% by weight of raw materials, distilled water, continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com