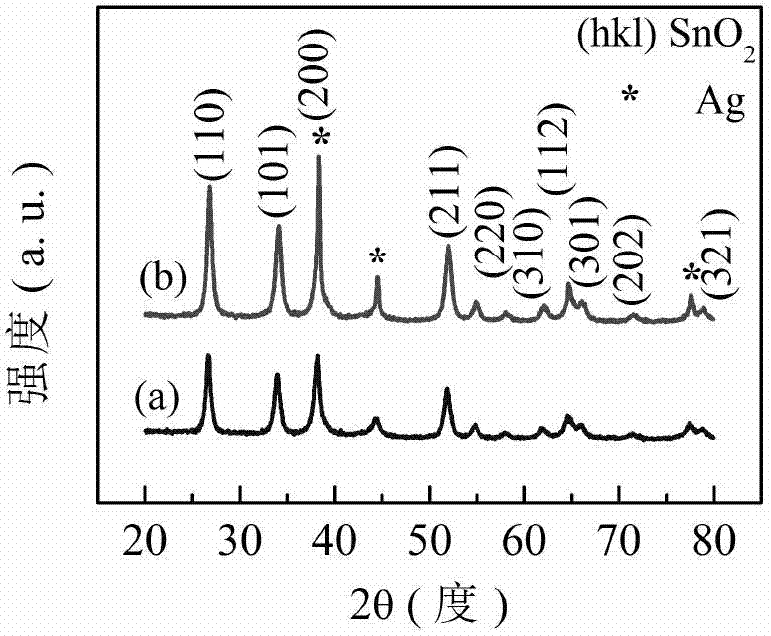

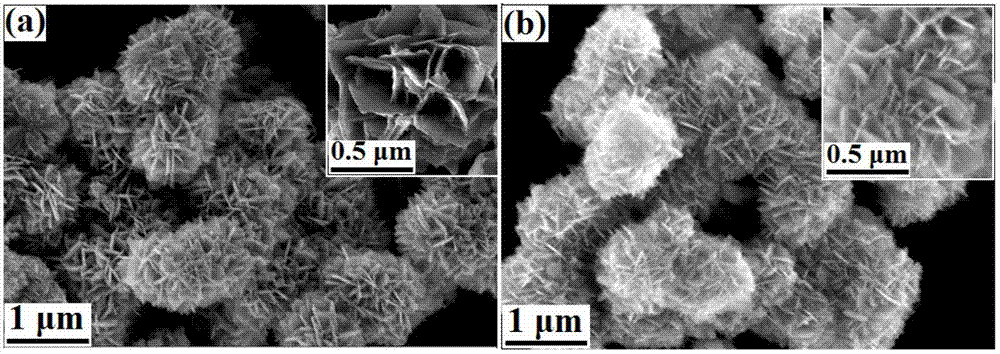

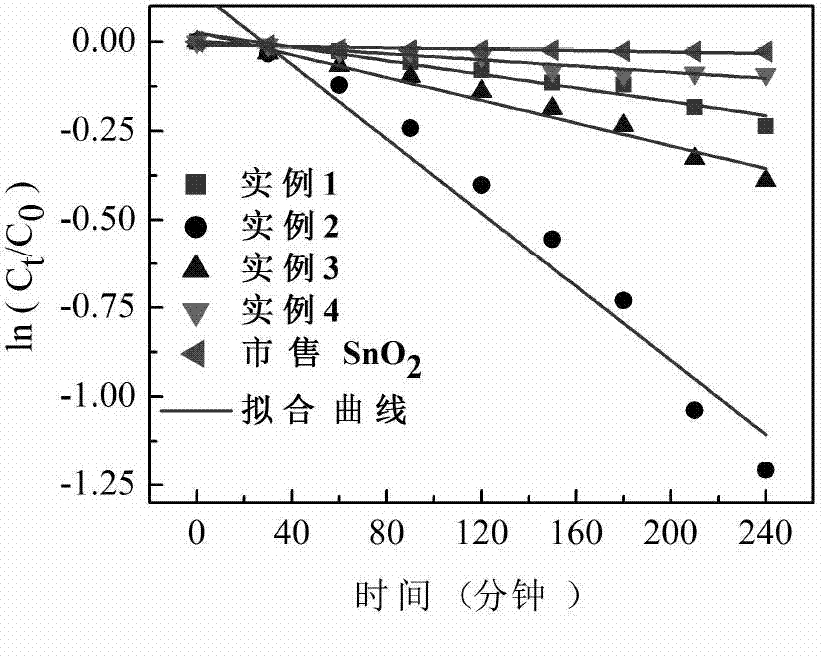

Preparation method of flower-like tin oxide/silver heterojunction material

A technology of tin oxide and heterojunction, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. Such as the limitation of photocatalytic performance and gas-sensing performance, etc., to achieve the effect of accurate process parameters, accurate control of process parameters, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, with 0.9026gSnCl 2 2H 2 O and 0.2941gNa 3 C 6 h 5 o 7 2H 2 O was added to 30ml of deionized water, stirred magnetically for 10min, and mixed evenly; added 0.06g flake NaOH, stirred magnetically for 10min, mixed evenly; at the same time, mixed 0.1019g AgNO 3 Add it into 10ml of deionized water, stir it magnetically for 10min to prepare a uniform solution, then add it to the aforementioned mixed solution, and continue magnetic stirring for 10min; transfer the mixed solution to a reaction tank made of polytetrafluoroethylene, tighten the container, and put Put it into a microwave reactor, heat it to 150°C, and keep it warm for 1.5h; after the reaction is completed and cooled to room temperature, pour out the solution in the reaction vessel, and repeatedly wash and filter with deionized water and absolute ethanol until the filtered deionized The pH of the water is 7, dry at 60°C; at 1°C min -1 The temperature was raised to 450°C at a certain rate, and k...

Embodiment 2

[0020] Embodiment 2, 0.9477gSnCl 2 2H 2 O and 3.088gNa 3 C 6 h 5 o 7 2H 2 O was added to 35ml of deionized water, stirred magnetically for 15min to make it evenly mixed; added 0.084g flake NaOH, stirred magnetically for 15min, and mixed evenly; at the same time, 0.1698g AgNO 3 Add it into 10ml of deionized water, stir it magnetically for 15 minutes to prepare a uniform solution, add it to the aforementioned mixed solution, and continue magnetically stirring it for 15 minutes; transfer the mixed solution to a reaction tank made of polytetrafluoroethylene, tighten the container, and put Put it into a microwave reactor, heat it to 180°C, and keep it warm for 1.3h; after the reaction is completed and cooled to room temperature, pour out the solution in the reaction vessel, wash and filter it repeatedly with deionized water and absolute ethanol until the filtered deionized The pH of the water is 7, dry at 60°C; at 2°C min -1 The temperature was raised to 500°C at a certain r...

Embodiment 3

[0022] Embodiment 3, 1.0831gSnCl 2 2H 2 O and 3.5292gNa 3 C 6 h 5 o 7 2H 2 O was added to 40ml of deionized water, stirred magnetically for 20min, and mixed evenly; added 0.096g flake NaOH, stirred magnetically for 20min, mixed evenly; at the same time, 0.3396gAgNO 3 Add it into 10ml of deionized water, stir magnetically for 20min to prepare a homogeneous solution, add it to the aforementioned mixed solution, and continue magnetically stirring for 20min; transfer the mixed solution to a reaction tank made of polytetrafluoroethylene, tighten the container, and pack Put it into a microwave reactor, heat it to 200°C, and keep it warm for 1h; after the reaction is completed and cooled to room temperature, pour out the solution in the reaction vessel, and repeatedly wash and filter with deionized water and absolute ethanol until the filtered deionized water The pH value is 7, dried at 60°C; at 2°C min -1 The temperature was raised to 550°C at a certain rate, and kept for 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com