Tapered blade wire-cutting mechanism for wire-stripping machine

A wire stripping machine and blade technology, which is used in equipment for dismantling/armoring cables, metal processing, etc., can solve the problems of insufficient precision part, unadjustable position, unadjustable stroke, etc., and achieves high driving force and long service life. , the effect of adjustable stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

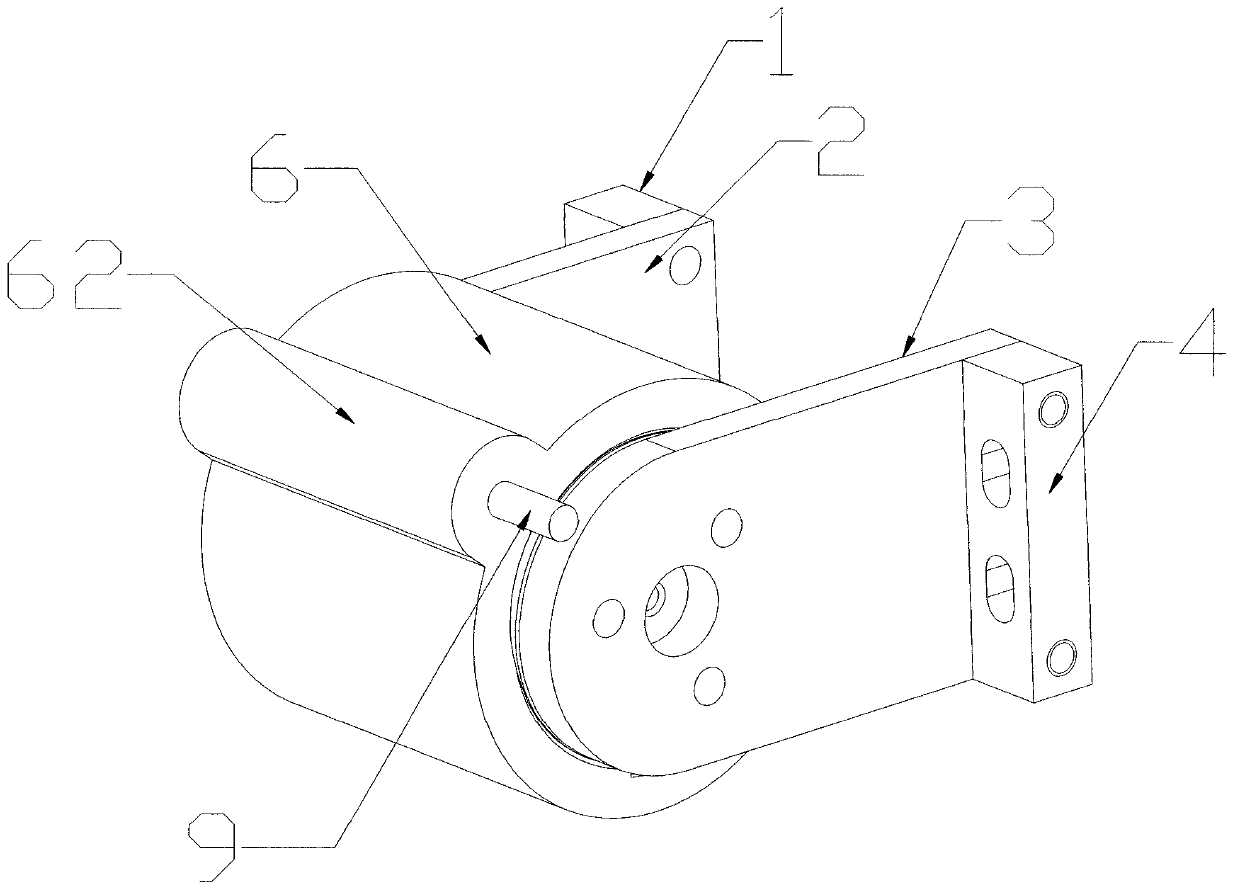

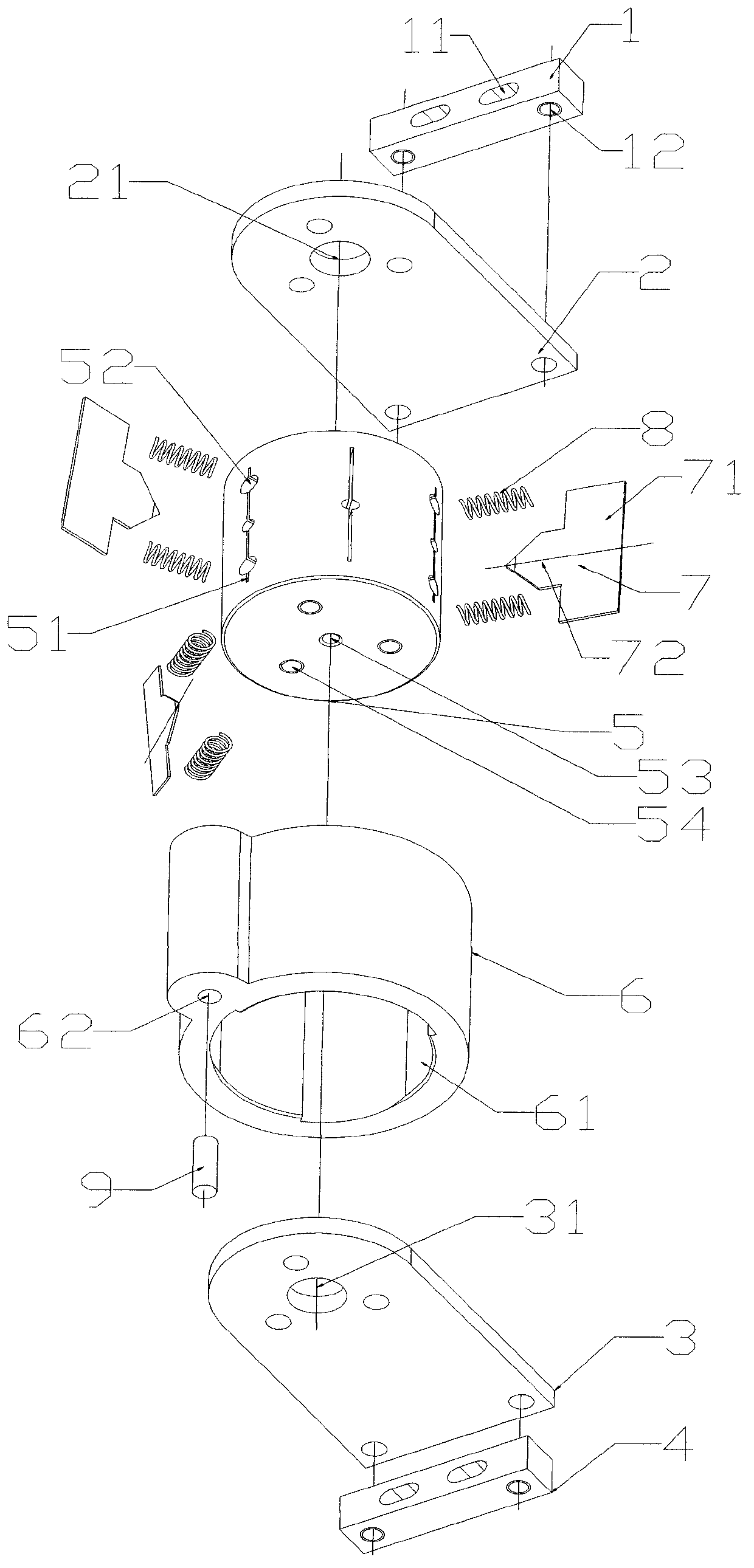

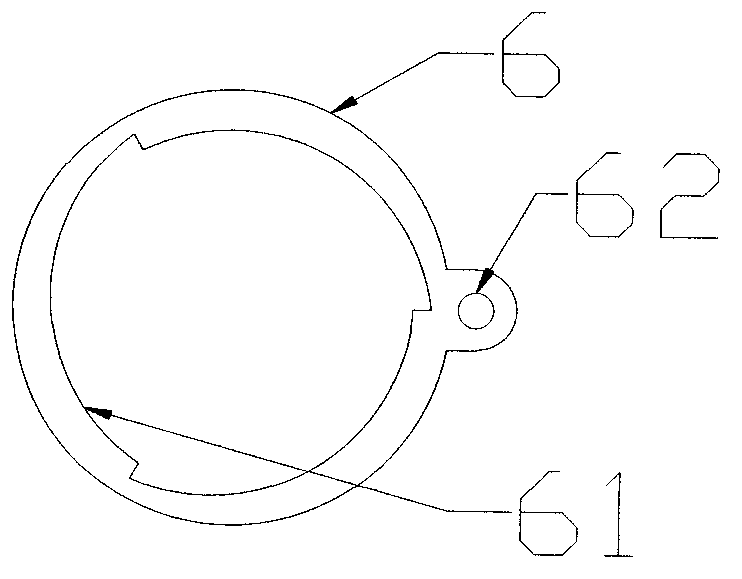

[0023] Such as Figure 1 to Figure 8 As shown, a tapered blade thread cutting mechanism applied to a wire stripping machine of the present invention is composed of a driving device and a knife holder, wherein the driving device is provided with a cylinder 111, a cylinder fixing frame and a mounting mounting; one end of the mounting mounting The panel of the wire stripping machine is fixedly connected by screws, and the other end is hinged with the cylinder fixing frame through the hinge shaft 116; the cylinder fixing frame is fixedly connected with the cylinder 111 by screws; the cylinder 111 is composed of a cylinder body and a piston rod; Knife rest is provided with stator 5, rotor 6, blade group, spring group and fixed frame and is formed; Said fixed frame is fixedly installed on the wire stripper panel, and the left fixed frame with threading hole 21, and is fixedly installed on the stripping machine panel. On the thread machine panel, and the right fixing frame with threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com