Device for slag-free production using bauxite or red mud

A technology of bauxite and red mud, applied in the direction of alumina/hydroxide, energy input, etc., can solve the problems of slag spit, waste of resources, increase of production cost, etc., and achieve the effect of reducing production cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

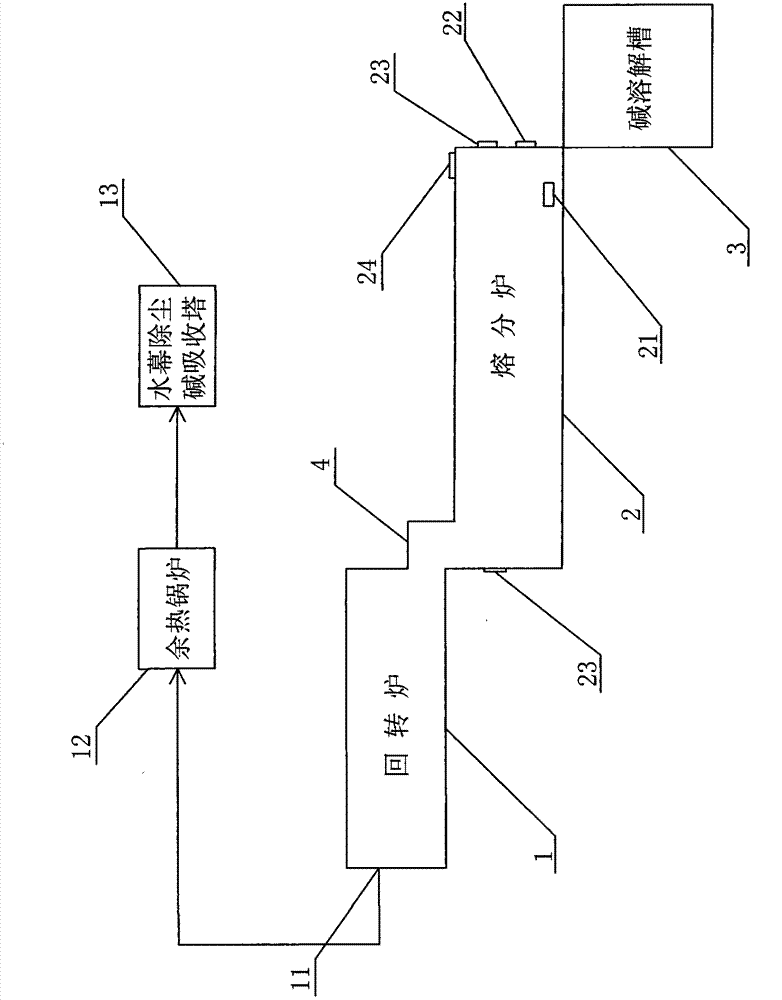

[0021] Such as figure 1 As shown, during installation, the positions of the rotary furnace 1, the melting furnace 2, and the alkali dissolution tank 3 are successively lowered, and the heights of their heads or lower parts are lower than their tails or upper parts. That is: the head of rotary furnace 1 is slightly lower than its tail; the tail of melting furnace 2 is lower than the head of rotary furnace 1, but higher than the head of melting furnace 2; the top of alkali dissolution tank 3 is lower than melting The head of sub-furnace 2, but higher than the bottom of alkali dissolution tank 3.

[0022] see figure 1 , a device for slag-free production using bauxite or red mud, including a rotary furnace 1, a melting furnace 2, and a closed channel 4, and the melting furnace 2 communicates with the rotary furnace 1 through the closed channel 4 The tail of the rotary furnace 1 is provided with a flue gas outlet 11, the lower side of the head of the melting furnace 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com