Preparation method of high-purity isomaltose hypgather

A high-purity isomaltose oligosaccharide technology, which is applied in the field of preparation of high-purity isomaltose oligosaccharides, can solve the problems that the isomaltooligosaccharides process has not yet been studied, and achieve the effect of reducing processing burden, reducing pollution and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

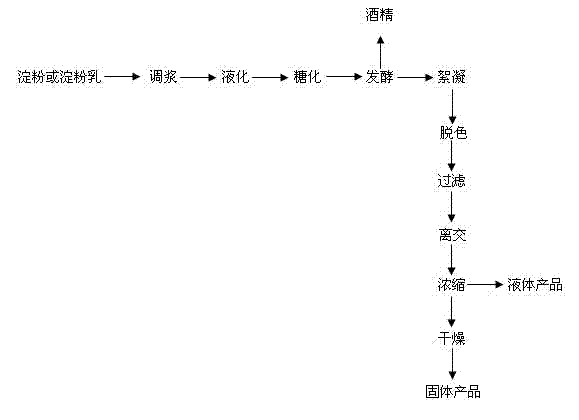

Method used

Image

Examples

Embodiment 1

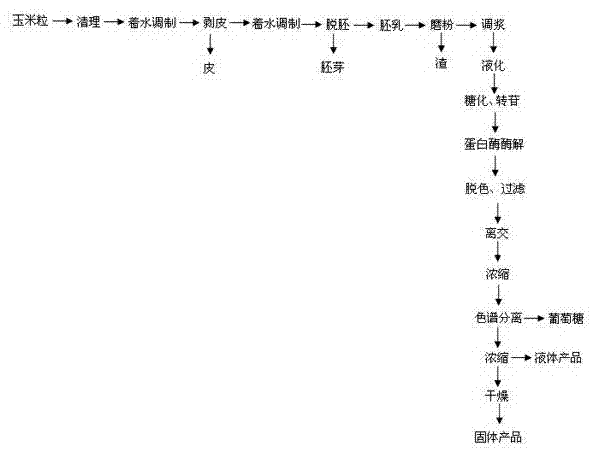

[0020] 1.1, Milling

[0021] After the corn kernels are cleaned of impurities and stones, they are prepared with water to make the total moisture of the corn kernels reach 16%, the water temperature is 40°C, and the time is 5 minutes, and then transported to the peeling equipment for the separation of the cortex, using "gradual pressure and rotary peeling" , so that the corn cortex is completely separated from the kernel and quickly sucked out of the peeling room, and the unpeeled corn continues to be peeled repeatedly. The sifted skin is powdered, and the powder from the belt is recovered.

[0022] The peeled corn is watered again to make the total moisture of the corn reach 19%, and the time is 1.5h, and then the embryo is broken. After the embryo is sieved, the separated germ is powdered, and the powder brought out by the germ is recovered. , after breaking the embryo, the crushed corn is screened and entered into the mill to be crushed into 80-100 mesh corn flour, the cor...

Embodiment example 2

[0028] 2.1, Milling

[0029] After the corn kernels are cleaned of impurities and stones, they are prepared with water to make the total moisture of the corn kernels reach 18%, the water temperature is 30°C, and the time is 10 minutes, and then transported to the peeling equipment for the separation of the cortex, using "gradual pressure and rotary peeling" , so that the corn cortex is completely separated from the kernel and quickly sucked out of the peeling room, and the unpeeled corn continues to be peeled repeatedly. The sifted skin is powdered, and the powder from the belt is recovered.

[0030] The peeled corn is watered again to make the total moisture of the corn reach 20% for 1 hour, and then the embryo is broken. After the embryo is sieved, the separated germ is powdered and the powder brought out by the germ is recovered. After breaking the embryo, the groat corn is screened and entered into a mill to be crushed into 80-100 mesh corn flour with a fat content of 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com