Natural cobalt iron chlorophyllin and preparation method thereof

A technology of chlorophyll and iron-cobalt, which is applied in the field of natural pigment salt and its preparation, and achieves the effects of simple and convenient preparation method, high yield and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

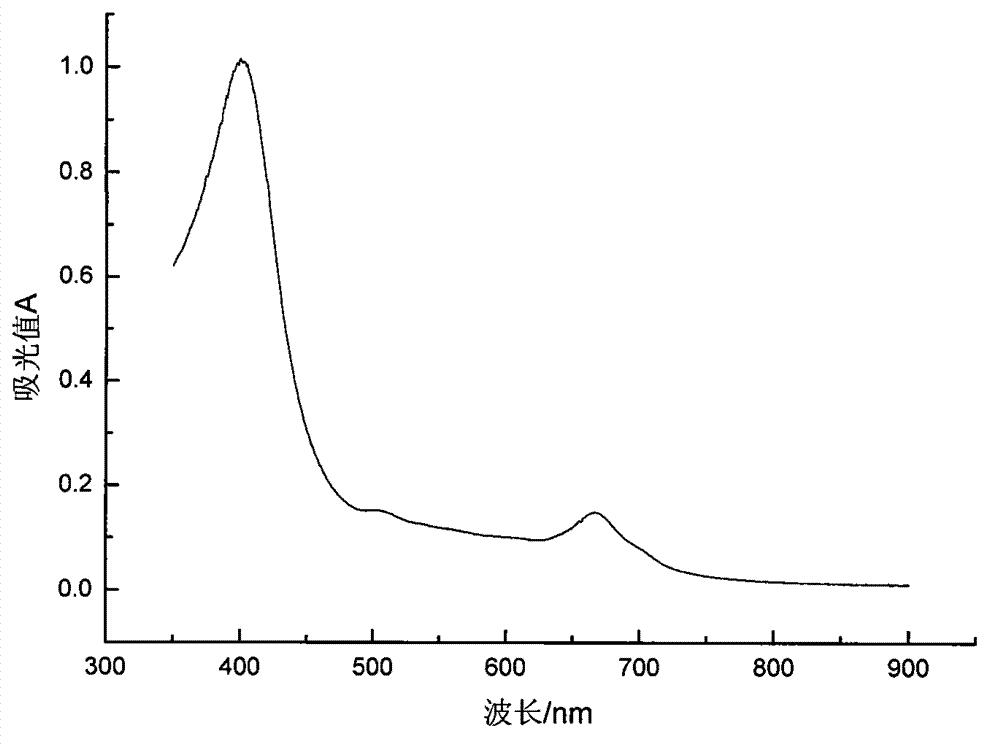

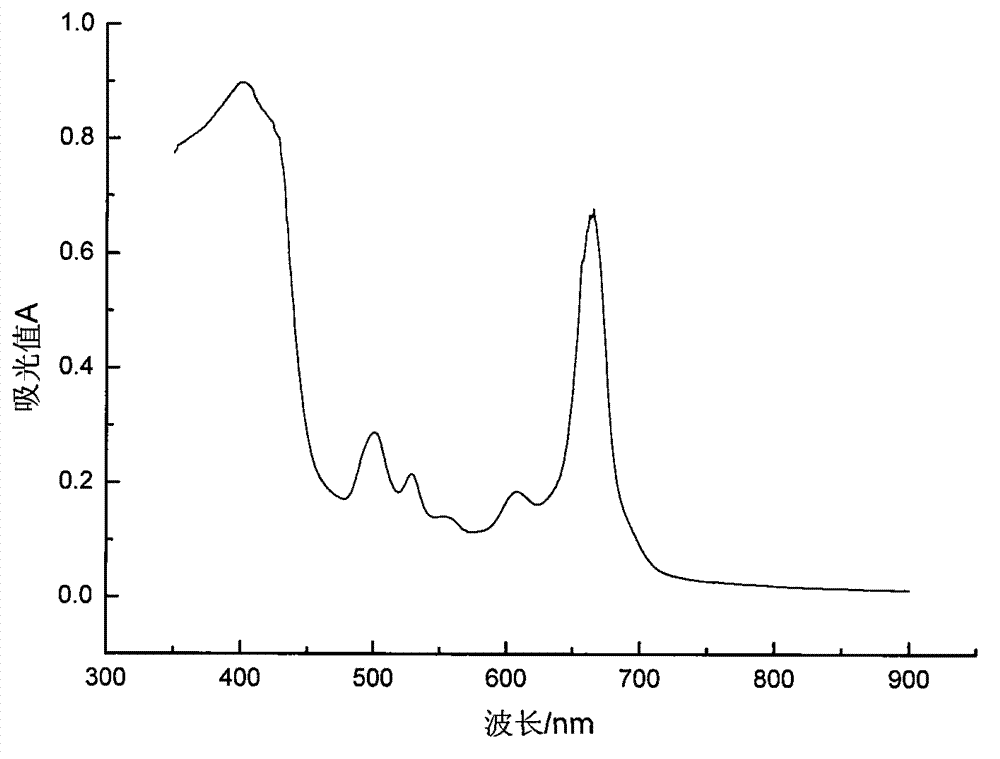

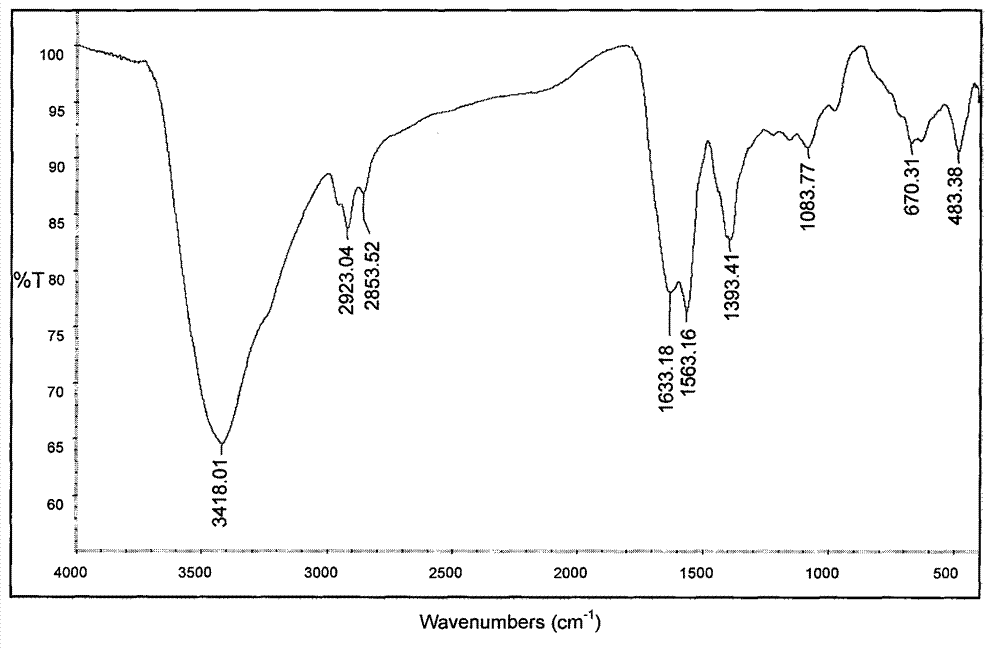

[0026] Sodium iron chlorophyllin dissolves in water with a concentration of 0.67g / 100ml dark green solution, and cobalt salt dissolves in water as a pink liquid. The cobalt salt solution was added to the sodium iron chlorophyllin salt, stirred at a speed of 1000r / min, fully reacted at room temperature, and aged at room temperature 25°C for 3h. Separation by filtration and drying at 80°C to obtain black (black-green) chlorophyll iron-cobalt salt. Carry out the measurement of each index. Wherein, by AVATAR360 type Fourier transform infrared spectrometer, UV7652 spectrophotometer, obtain chlorophyll iron sodium salt and chlorophyll iron cobalt salt spectrogram (see attached Figure 1~4 ), and analyzed and compared, it was determined that the product was chlorophyll iron cobalt salt.

[0027] The calculated yield was 81%.

Embodiment 2

[0029] Chlorophyll iron sodium salt and cobalt salt are dissolved in water respectively. Add the cobalt salt solution to the sodium ferric chlorophyllin. Stir at a speed of 800r / min, make it fully react at room temperature, and age at room temperature 21°C for 9h. Separate by filtration and dry at 60°C to obtain black (black-green) chlorophyll iron-cobalt salt. Carry out the measurement of each index.

[0030] The calculated yield was 90%.

Embodiment 3

[0032] Chlorophyll iron sodium salt and cobalt salt are dissolved in water respectively. Add the cobalt salt solution to the sodium ferric chlorophyllin. Stir at a speed of 1200r / min, and age at room temperature 17°C for 7h. Separation by filtration and drying at 50°C to obtain black (black-green) chlorophyll iron-cobalt salt. Carry out the measurement of each index.

[0033] The calculated yield was 86%.

[0034] Salt formation analysis of chlorophyll iron and cobalt:

[0035] 1. Salt-forming reaction equation

[0036]

[0037] 2. Analysis of experimental principles

[0038] The iron in the center of the chlorophyll iron sodium salt ring is relatively stable, but the concentration and medium conditions controlled in this experiment do not meet the requirements for the center metal to be replaced. In addition, the distance between the center of the porphyrin ring and the N atom in the molecular structure of iron chlorophyllin sodium salt is 204pm, and the radius of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption frequency | aaaaa | aaaaa |

| absorption frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com