Method and device of laser impact fine tuning

A laser shock and laser technology, applied in the field of fine-tuning of micro-mechanical cantilever beams, laser shock fine-tuning method and device, and fine-tuning of metal surface curvature, can solve the problem of difficult control of contact mechanical fine-tuning accuracy and large temperature effect , Difficult to fine-tune, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as Figure 1-3 shown.

[0027] A laser shock fine-tuning method, it comprises the following steps:

[0028] First, polish the cantilever-shaped target to ensure the smoothness and flatness of the target surface, and clean the target surface with anhydrous alcohol to ensure the cleanliness of the target;

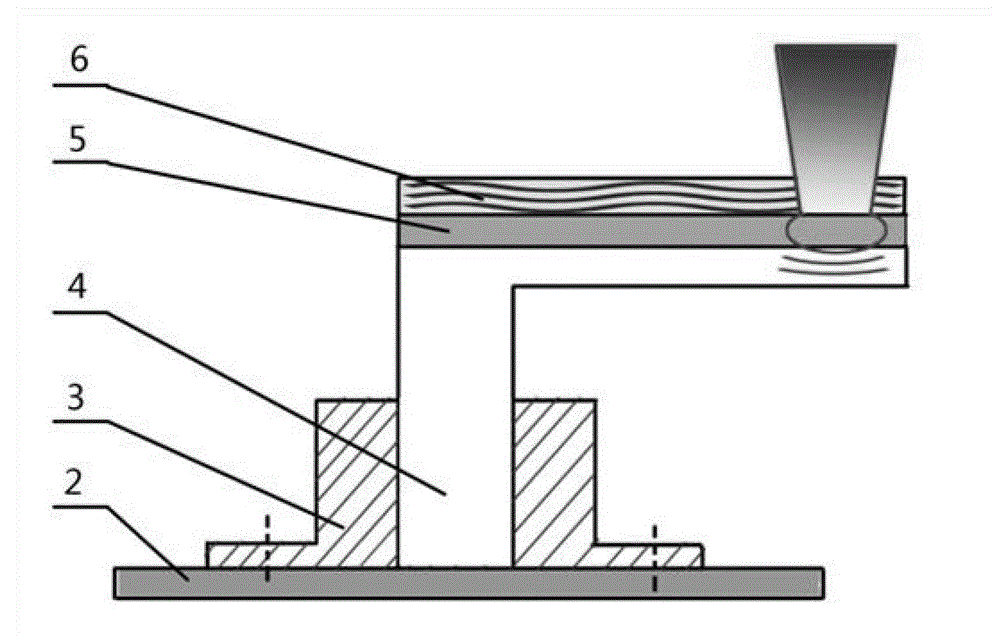

[0029] Secondly, apply black paint on the surface of the target to form an opaque layer coating to ensure the absorption rate of the target to the laser; control the thickness of the black paint coating to 10-30 microns, see figure 2 ;

[0030] Third, put the target material coated with black paint into the water as the constraining layer, and use water as the constraining layer to cover the surface of the black paint; control the water depth to be 1-2 mm above the black paint layer, see figure 2 ;

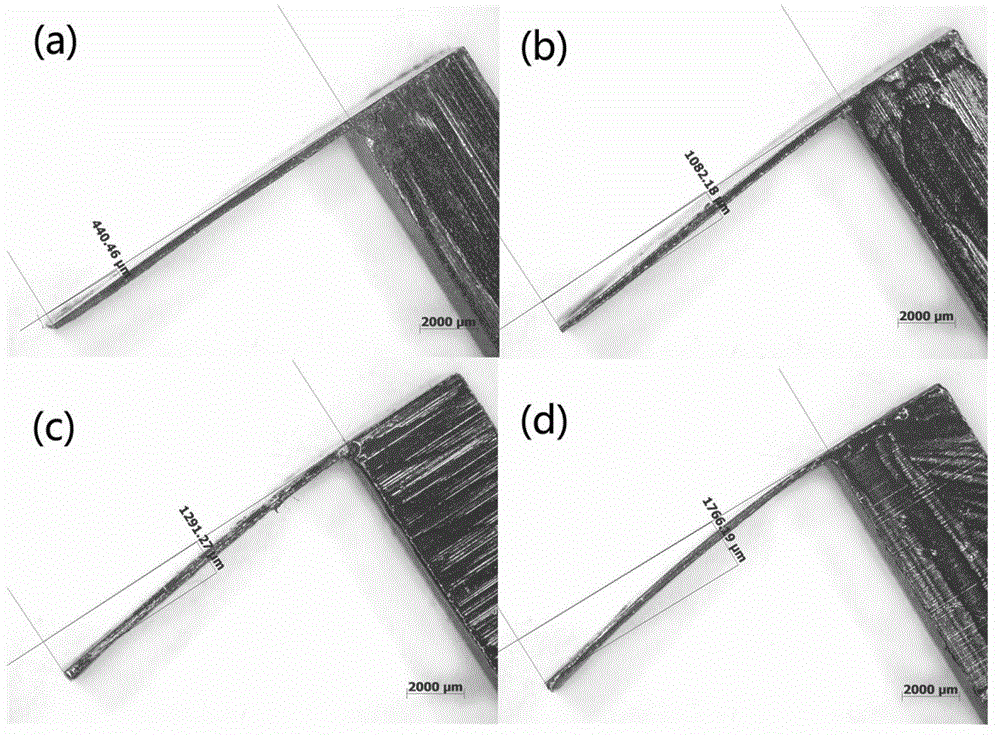

[0031] Fourth, fasten one end of the target with a fixture, and the other end is cantilevered to ensure the position, turn on the nanosecond pulse laser, ad...

Embodiment 2

[0035] Such as Figure 1-3 shown.

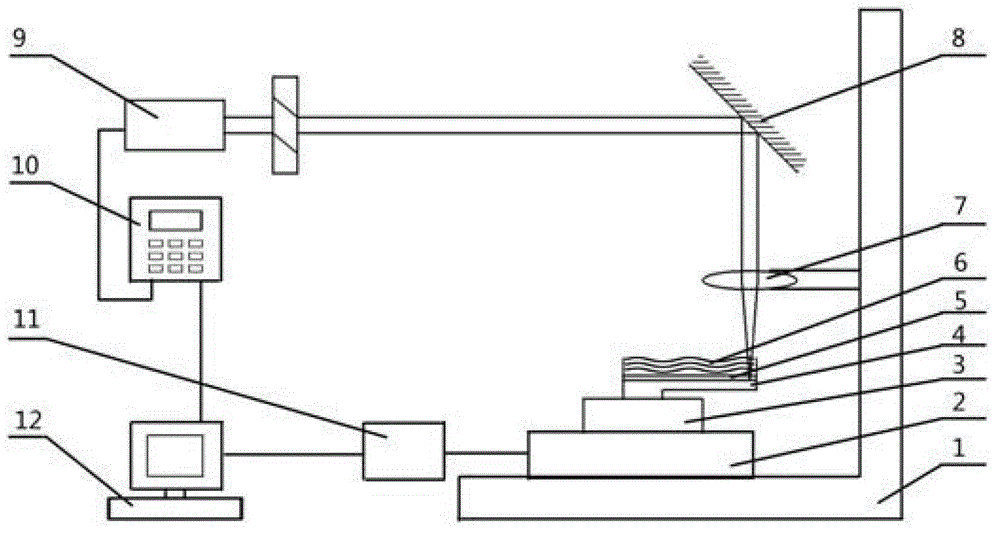

[0036] A laser shock fine-tuning calibration device, which consists of a laser drive control system, a target system and a target clamping displacement system, such as figure 1 As shown, the laser drive control system consists of a computer 12, a laser controller 10, a nanosecond laser 9, a plane mirror 8 and a focusing lens 7. The computer 12 controls the laser controller 10, and the laser controller 10 controls the nanosecond laser 9. The laser beam is reflected to the focusing lens 7 after being reflected by the plane mirror 8 and then directly enters the target system; the target system is composed of a water layer 6, a black paint layer 5 and a target material 4, and the water layer is used as a constraining layer to cover the surface coated with black paint. The upper surface of the target layer, such as figure 2 ; The entire target system is clamped on the target clamping displacement system; the target clamping displacement system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com