Pickled vegetable brine produced by using white wine byproducts, and preparation method thereof

A technology for pickle brine and by-products, which is applied to the field of pickle brine produced by using liquor by-products and its preparation field, can solve problems such as environmental pollution, waste of renewable resources and the like, shorten fermentation time, realize comprehensive development and utilization, and have a sour taste. Crispy and refreshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

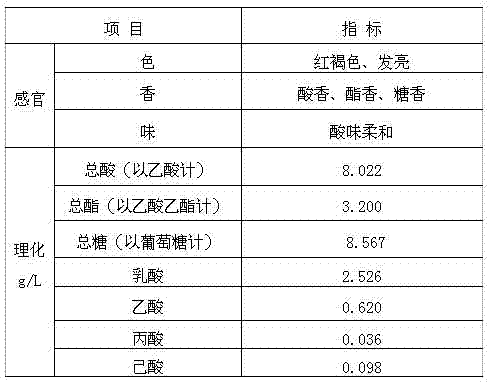

Embodiment 1

[0057] A pickle brine produced by using liquor by-products, with 1L of esterification raffinate as the base material, and the following auxiliary materials:

[0058] Clove: 10g Green chili: 20g Ginger: 10g

[0059] Arrow grass: 5 g Chinese prickly ash: 5 g Star anise: 8 g

[0060] White fungus: 7g Orange peel: 5g Salt: 30g

[0061] Its preparation process is as follows:

[0062] Wash and dry 20g green peppers and remove the stalks; scrape off the rough skin of 10g ginger, remove the sharp beak and old skin; then cut the green peppers and ginger into 1mm-5mm filaments, and then wrap the two ingredients in double layers Make pepper packs in gauze.

[0063] Wrap 5 g orange peel, 7 g white fungus, 8 g star anise, 5 g prickly ash, 5 g papaya, and 10 g clove in a single layer of gauze to make a spice bag.

[0064] Stir-fry 30g of table salt in a pot over low heat for 2 minutes, then add it into 1L of the remaining esterification liquid and mix evenly, stir to fully dissolve the ...

Embodiment 2

[0071] A pickle brine produced by using liquor by-products, with 1L of esterification raffinate as the base material, and the following auxiliary materials:

[0072] Clove: 15g Green chili: 30g Ginger: 40g

[0073] Arrow grass: 3g Chinese prickly ash: 2g Star anise: 5g

[0074] White fungus: 10g Orange peel: 10g Salt: 50g

[0075] Its preparation process is as follows:

[0076] Wash and dry 30g green peppers and remove the stalks; scrape off the rough skin of 40g ginger, remove the sharp beak and old skin; then cut the green peppers and ginger into 1mm-5mm filaments, and then wrap the two ingredients in double layers Make chili packets in gauze.

[0077] Wrap 10g of orange peel, 10g of white fungus, 5g of star anise, 2g of Zanthoxylum bungeanum, 3g of grass, and 15g of clove in a single layer of gauze to make a spice bag.

[0078] Stir-fry 50g of table salt in a pot over low heat for 3 minutes, then add it into 1L of the remaining esterification liquid and mix evenly, stir...

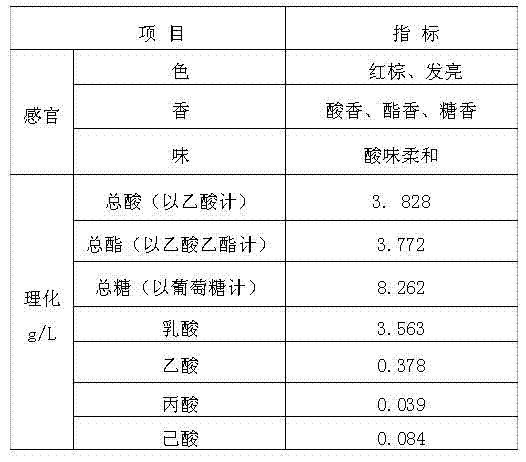

Embodiment 3

[0085] A pickle brine produced by using liquor by-products, with 1L of esterification raffinate as the base material, and the following auxiliary materials:

[0086] Clove: 8g Green chili: 18g Ginger: 20g

[0087] Arrow grass: 6g Chinese prickly ash: 3g Star anise: 6g

[0088] White fungus: 6g Orange peel: 5g Salt: 32g

[0089] Its preparation process is as follows:

[0090] Wash and dry 8g green peppers and remove the stalks; scrape off the rough skin of 20g ginger, remove the sharp beak and old skin; then cut the green peppers and ginger into 1mm-5mm filaments, and then wrap the two ingredients in double layers Make chili packets in gauze.

[0091] Wrap 5g of orange peel, 6g of white fungus, 6g of star anise, 3g of Zanthoxylum bungeanum, 6g of grass, and 8g of clove in a single layer of gauze to make a spice bag.

[0092] Stir-fry 32g of salt in a pot over low heat for 5 minutes, then add it into 1L of the remaining esterification liquid and mix evenly, stir to fully dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com