Thin substrate, mass-transfer bernoulli end-effector

一种端拾器、基片的技术,应用在半导体/固态器件制造、夹头、机械手等方向,能够解决增加真空管道系统复杂度、增加保持器成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

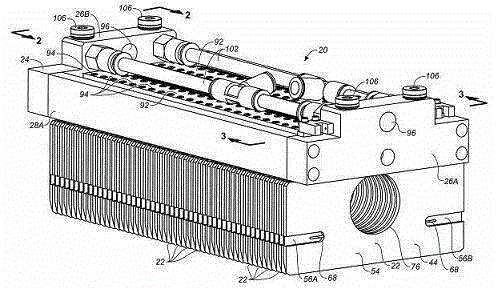

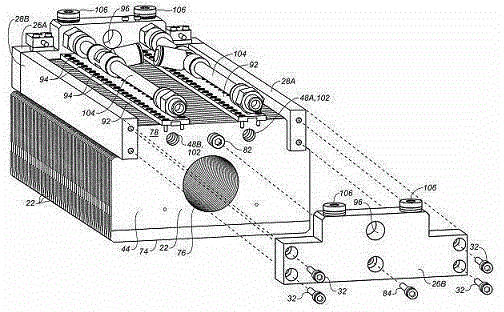

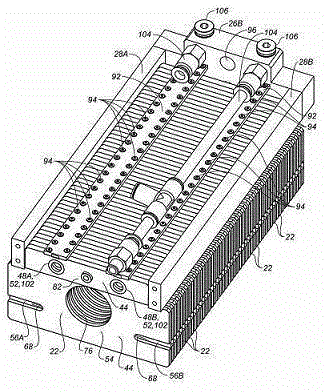

[0066] figure 1 Shown is a specific embodiment of the currently optimal batch transfer end effector represented by serial number 20, which is suitable for transferring a batch of thin semiconductor substrates at the same time. The end effector 20 includes a plurality of juxtaposed suction-finger substrate holders 22 , and a rectangular end-effector frame 24 surrounds and supports the upper half of the group of suction-finger substrate holders 22 . The end effector frame 24 includes a pair of end plates 26A, 26B at opposite ends of the end effector frame 24 and oriented parallel to the substrate holder 22 . Such as figure 2 and image 3 As shown, a pair of side rails 28A, 28B extend between opposite ends of the end panels 26A, 26B. Such as figure 2 As shown, a pair of fasteners 32 secure two ends of the end panels 26A, 26B to corresponding adjacent ends of the side rails 28A, 28B to establish the end effector frame 24 .

[0067] Figure 4 Indicated to include Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com