Multifunctional lifting principal line bedplate device

A multi-functional, mainline technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of high labor intensity for operators, complex overall correlation, and many types of equipment, so as to save site space and increase the range of lifting loads Large, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

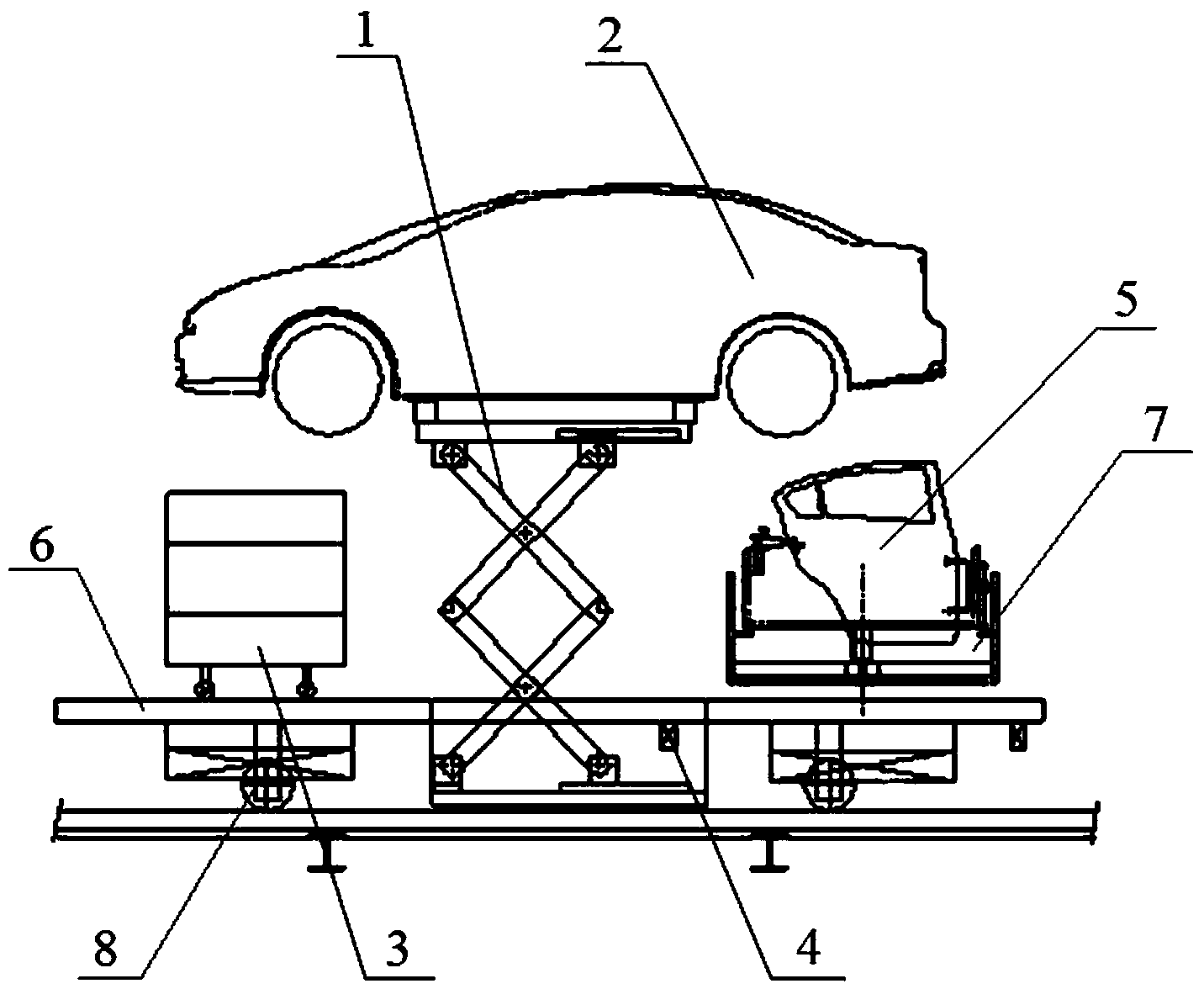

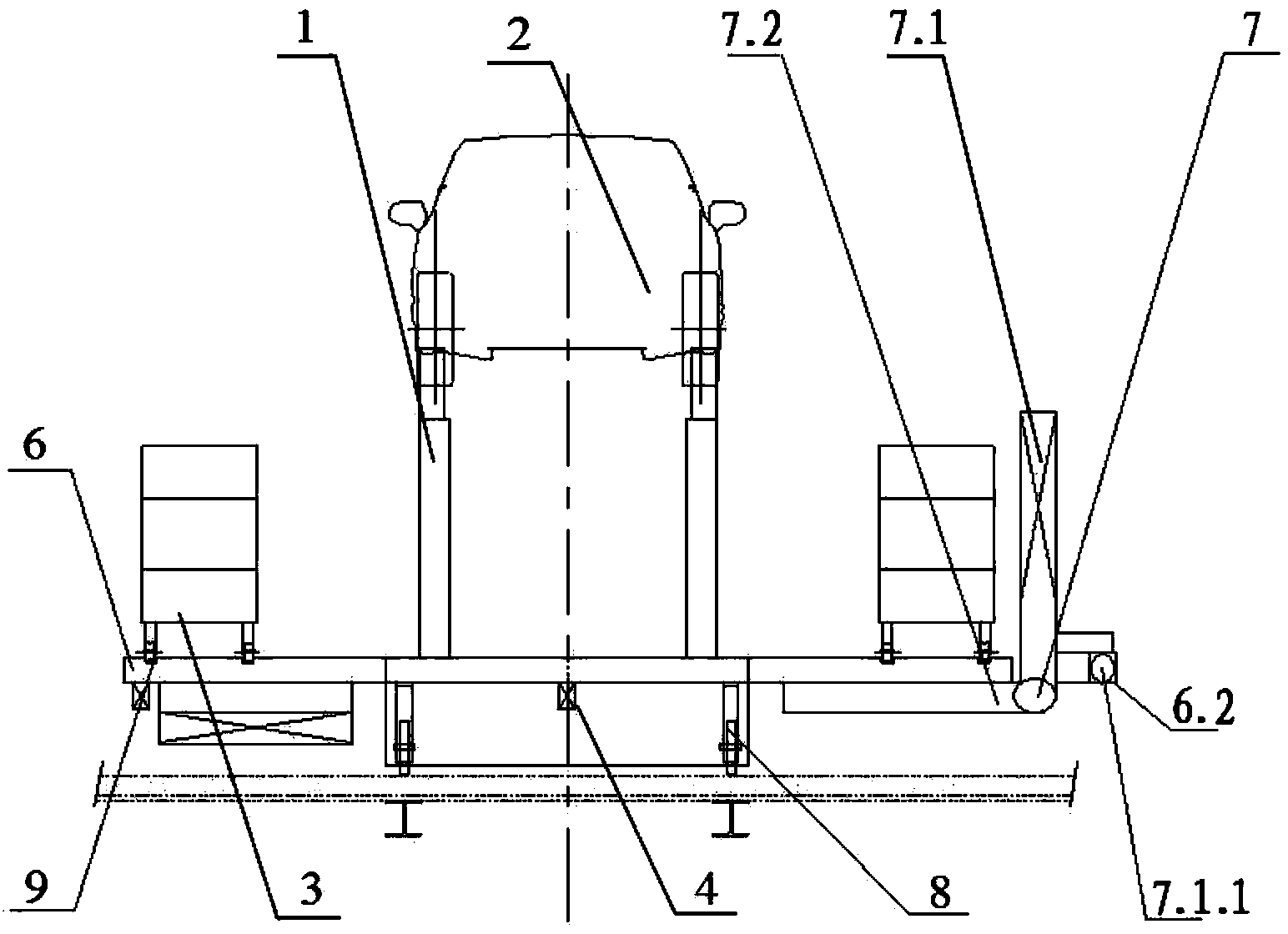

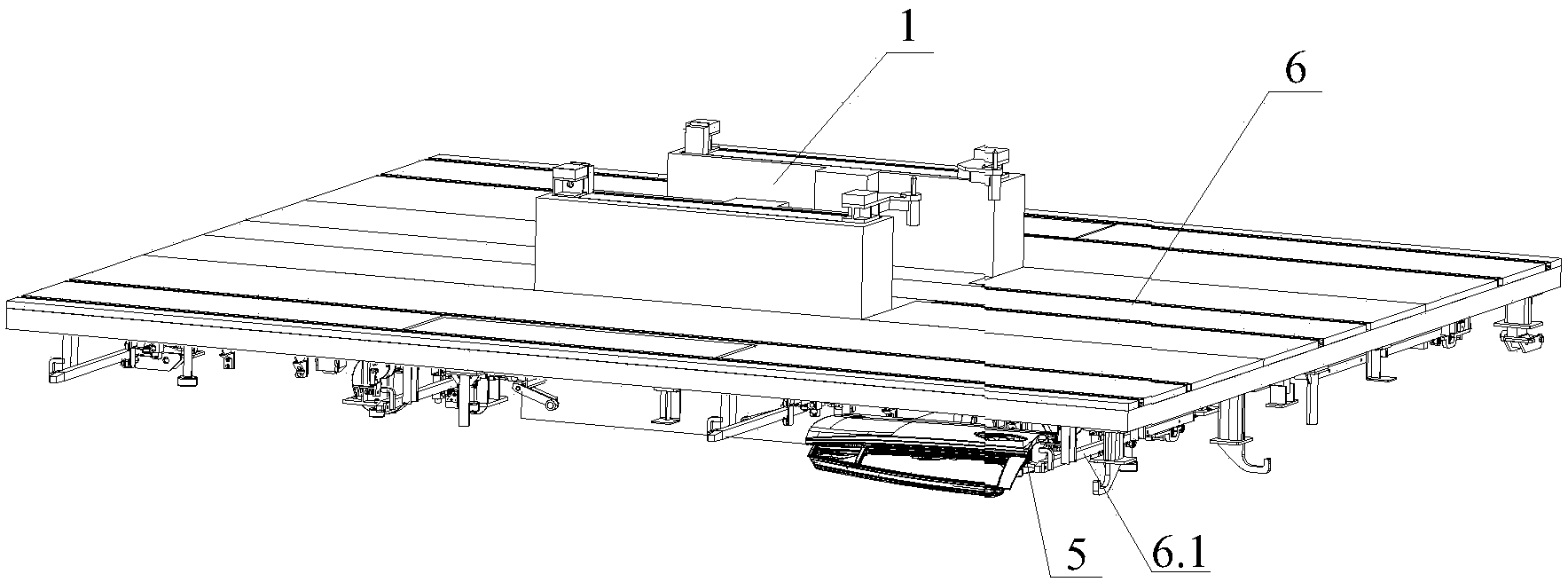

[0026] Such as figure 1 , figure 2 As shown, the present invention includes a platen 6 and a roller 8 arranged at the bottom of the platen 6, the platen 6 is provided with a liftable carrying device 1, and the carrying device 1 is connected to the power supply device 4; the platen 6 During the conveying process, the carrying device 1 provides power supply and control signals through the power supply device 4 to complete the ascent and descent, meet the process requirements and operation requirements of different stations, and ascend or descend to the required height. In the present invention, the workpiece (vehicle body) 2 is carried on the lifting device 1 on the platform 6; the material vehicle 3 is transported to the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com