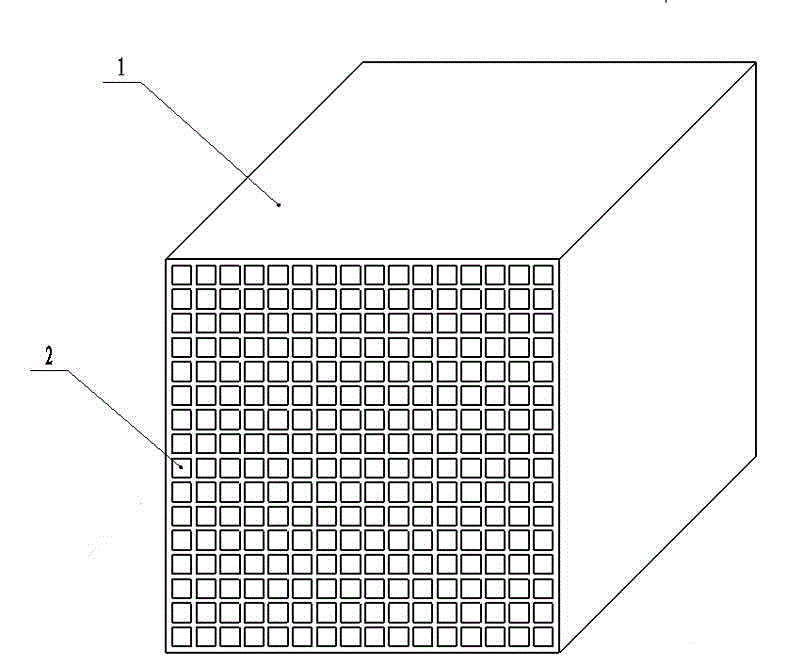

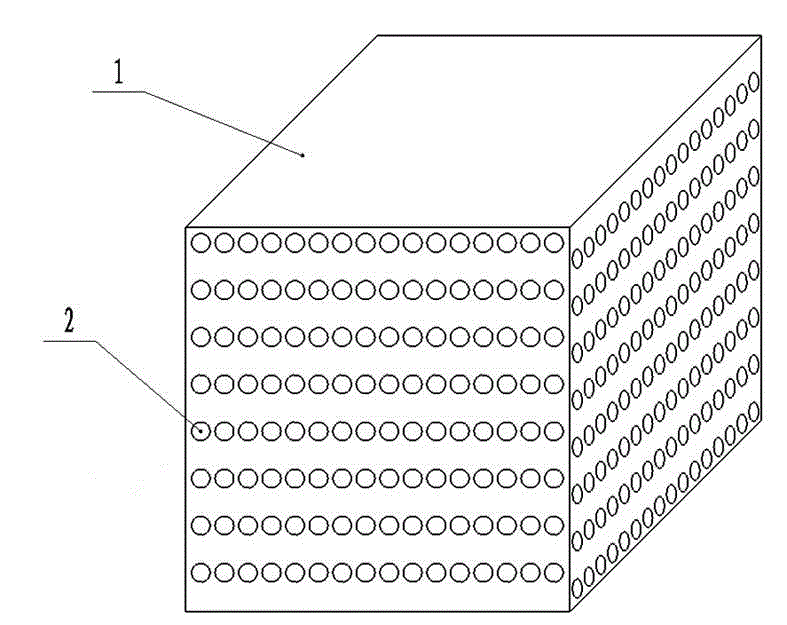

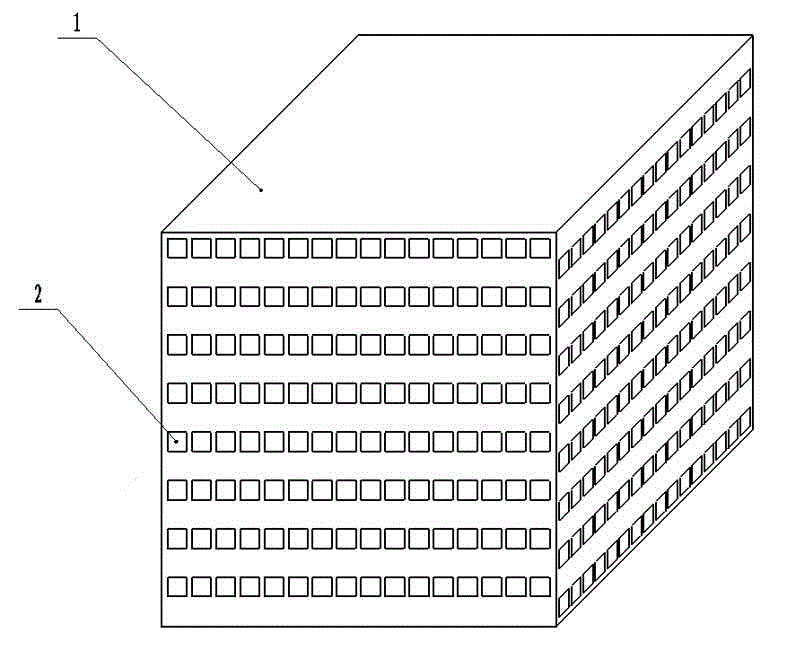

Honeycomb ceramic

A technology of honeycomb ceramic body and ceramic body, which is applied in the field of ceramics, can solve the problems of increasing the manufacturing cost and operating cost of a regenerative industrial furnace, and complicating the operation, so as to reduce the manufacturing cost and operating cost, and simplify the operation control system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 62 kg of sintered mullite, 16 kg of zirconia, 12 kg of kaolin, 1.5 kg of talcum powder, 1.5 kg of white corundum micropowder, 3.5 kg of binder, and 3.5 kg of paraffin, wherein the binder is composed of polyvinyl alcohol and cellulose by weight Prepared with a ratio of 45:55;

[0022] After mixing the above raw materials, add water with a weight of 35 kg of the mixture, fully mix and grind in a ball mill for 20 hours to make a slurry, pour the slurry into a mold after defoaming, and heat it to a temperature of 15°C. The slurry is naturally solidified and formed in the mold, and the formed green body is dried at 150°C for 10 hours, and then fired in a high-temperature furnace at 1380°C for 24 hours.

Embodiment 2

[0024] 85 kg of sintered mullite, 8 kg of zirconia, 3 kg of kaolin, 0.5 kg of talcum powder, 0.5 kg of white corundum micropowder, 1.5 kg of binder, and 1.5 kg of paraffin, wherein the binder is composed of polyvinyl alcohol and cellulose by weight 45:55 ratio composition;

[0025] After mixing the above raw materials, add water with a weight of 40 kg of the mixture, fully mix and grind in a ball mill for 25 hours to make a slurry, pour the slurry into a mold after defoaming, and heat it to a temperature of 105°C. The slurry is naturally solidified and formed in the mold, and the formed green body is dried at 180°C for 15 hours, and then fired in a high-temperature furnace at 1460°C for 36 hours.

Embodiment 3

[0027] 70 kg of sintered mullite, 17 kg of zirconia, 6 kg of kaolin, 1 kg of talcum powder, 1 kg of white corundum powder, 2.5 kg of binder, 2.5 kg of paraffin, wherein the binder is composed of polyvinyl propanol and cellulose by weight 45:55 ratio composition;

[0028] After mixing the above raw materials, add water with a weight of 36 kg of the mixture, fully mix and grind in a ball mill for 22 hours to make a slurry, pour the slurry into a mold after defoaming, and heat it to a temperature of 45°C. The slurry is naturally solidified and formed in the mold, and the formed green body is dried at 160°C for 12 hours, and then fired in a high-temperature furnace at 1400°C for 28 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com