Multi-mechanism combined driving device of roller coaster type full-automatic mahjong machine

A driving device, fully automatic technology, applied in sports accessories, indoor games, etc., can solve the problems of increased manufacturing cost and operating cost, cumbersome structure, and many driving motors, and achieve the effect of saving manufacturing cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

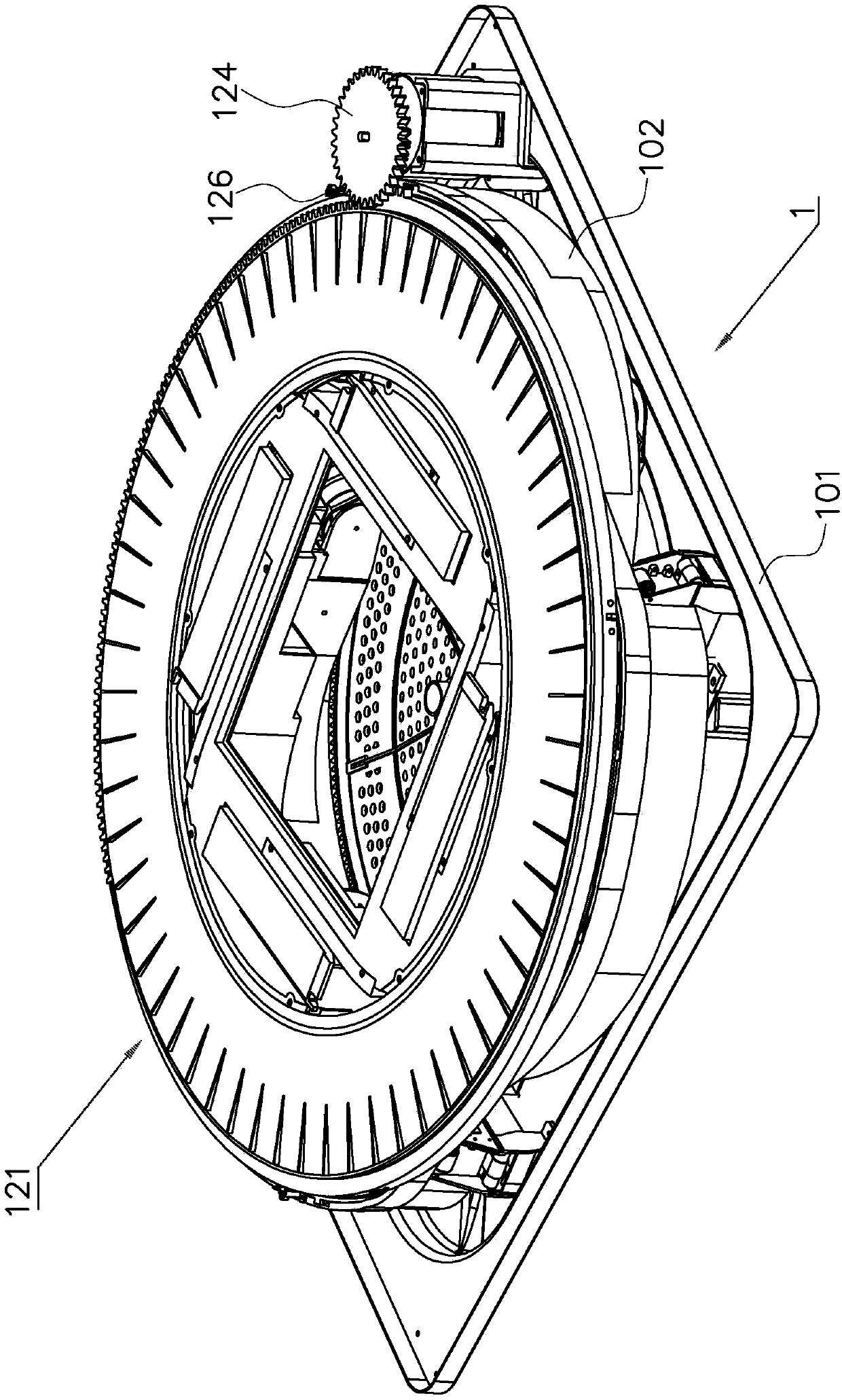

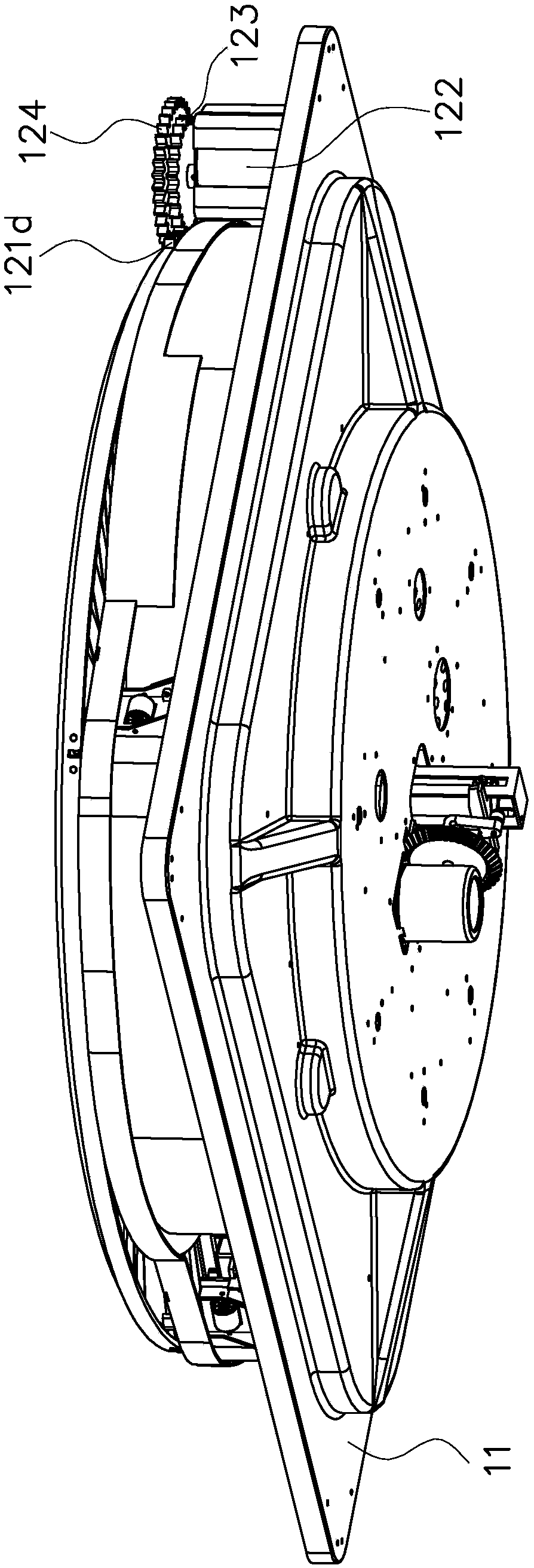

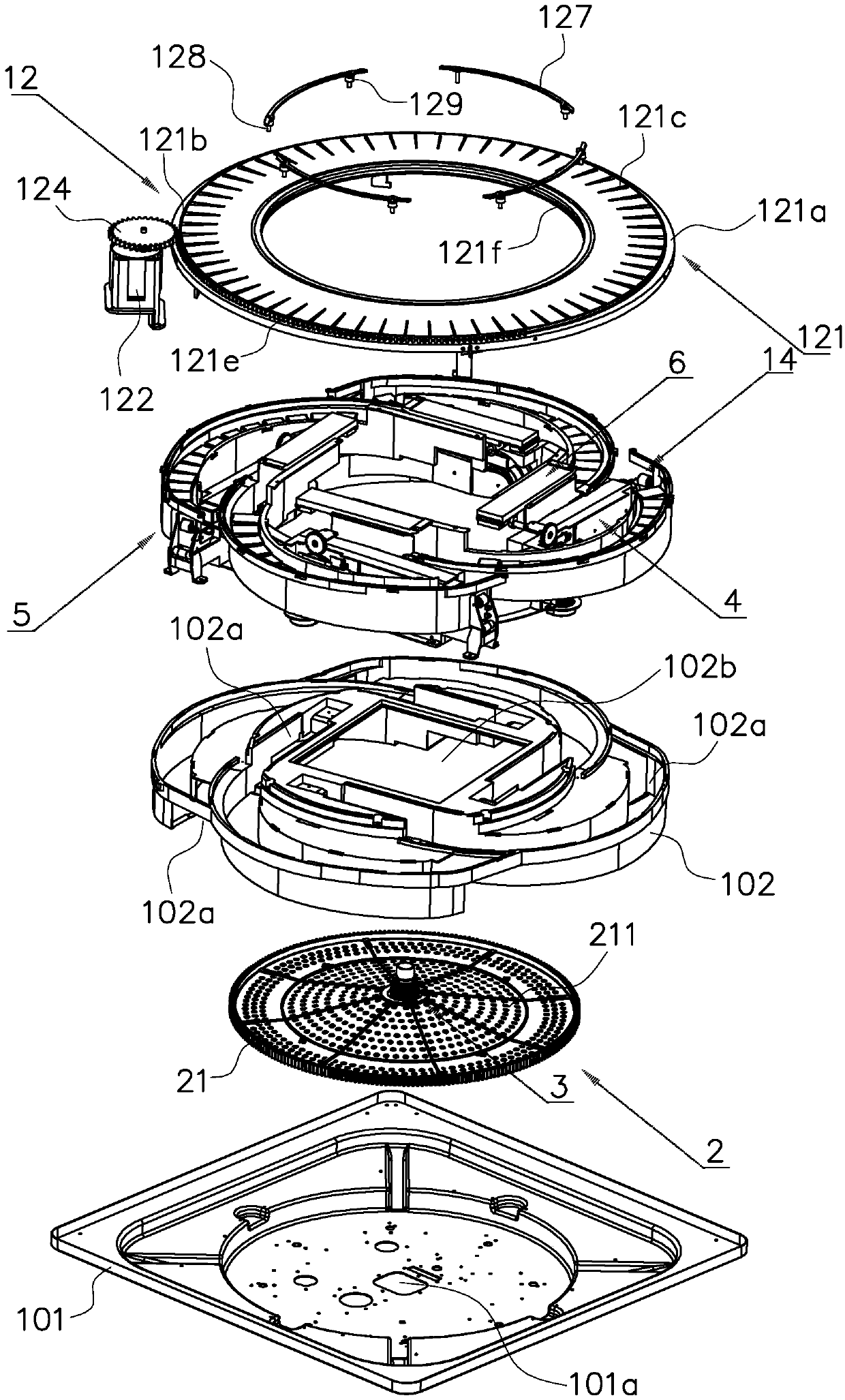

[0067] like figure 1 , figure 2 , image 3 and Figure 4 The shown roller coaster type automatic mahjong machine includes a base 1, the base 1 includes a base plate 101 and an integrally formed part 102 fixedly mounted on the baseplate 101. The center of the molded part 102 is provided with a shuffling bucket 102b, and a panel (not shown in the figure) is mounted on the top surface of the one-piece molded part 102 .

[0068] like Figure 5 and Figure 12 As shown, the multi-mechanism combined drive device of the roller coaster type automatic mahjong machine in this embodiment includes a shuffling mechanism 2, a central lifting mechanism 3, a card stacking mechanism 14 and a card lifting and receiving mechanism 6, wherein the card stacking mechanism 14 and the card raising and holding mechanism 6 are installed in the corresponding positioning and mounting parts 102a, and a positioning and mounting part 102a for installing the card delivery mechanism 13 is also formed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com