Mixing device for vehicle engine exhaust gas recirculation (EGR)

A technology for exhaust gas recirculation and vehicle engines, which is applied in the direction of exhaust gas recirculation, engine components, combustion engines, etc., can solve the problems of reducing exhaust gas, intake air mixing uniformity, etc., and achieves small intake pressure loss and enhanced stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

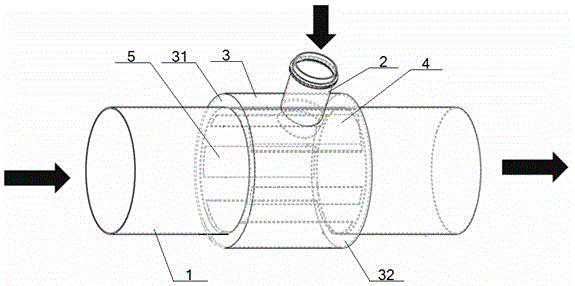

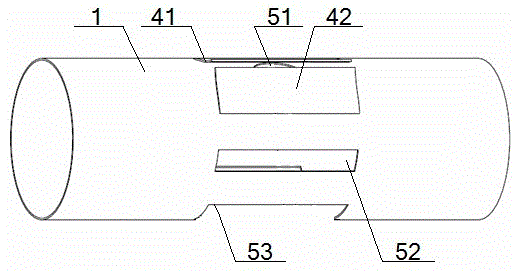

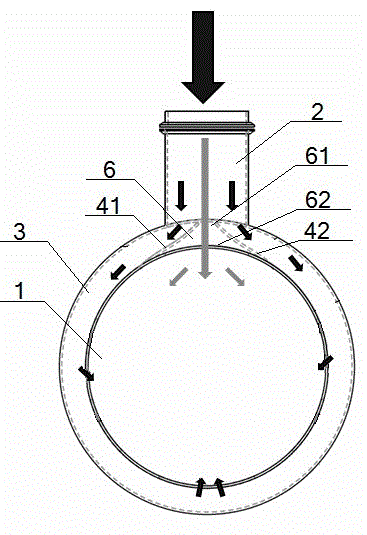

[0043] see figure 1 – image 3 , a mixing device for exhaust gas recirculation (EGR) of a vehicle engine, comprising an intake pipe 1, an exhaust pipe 2, a diversion shell 3 and an exhaust gas diversion device, and the exhaust gas diversion device includes a deflector 4 and an exhaust gas Channel 5, the deflector 4 includes a symmetrically arranged first deflector 41 and a second deflector 42, the first deflector 41 and the second deflector 42 are arc-shaped, and the first deflector The radians of the plate 41 and the second deflector 42 are consistent, and the exhaust gas channel 5 includes a front exhaust gas channel 51, a side exhaust gas channel 52 and a rear exhaust gas channel 53;

[0044] The side of the diversion shell 3 is vertically connected with the exhaust pipe 2, and the inside of the diversion shell 3 is provided with a coaxial air intake pipe 1. The outer walls are connected, one end of the No. 1 deflector 41 and the No. 2 deflector 42 are all connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com