Coal mining excavation saw

A tunnel sawing and sawing technology, which is applied in the field of cutting machinery, can solve the problems of the tunnel shearer being bulky, unable to cut the rear section, and the use space is relatively limited, so as to improve the use value and economy. Value, good for cooling and chip evacuation, easy to transport and store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

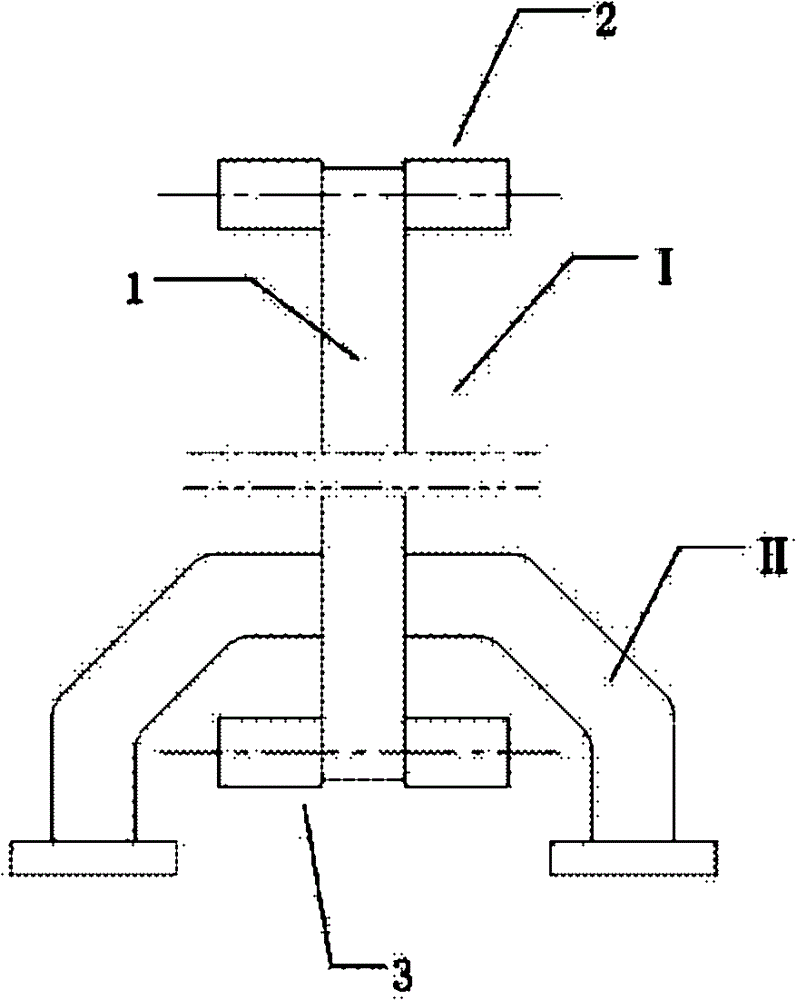

[0041] see Figure 1-Figure 16 , The tunneling saw provided by the present invention includes a machine body II and a sawing mechanism I. Saw mechanism 1 comprises driving wheel 3, driven wheel 2, saw blade 4, cooling device 12 and support frame 1. The body II includes a driving mechanism 5 connected to the driving wheel 3 . The saw blade 4 is wound around the driving wheel 3 and the driven wheel 2 in a tensioned state. A support frame 1 is arranged between the driving wheel 3 and the driven wheel 2, the front end of the support frame 1 is arranged between the two driven wheels 2, and the shaft of the support frame 1 is movably connected with the driven wheel 2. The cooling spray head of the cooling device 12 is arranged on the supporting frame 1 between the two wheels of the driven wheel 2. The part composed of the driving wheel 3, the driven wheel 2 and the supporting frame 1 is divided into a driving sawing part and a cutting part. The cross section of the saw blade 4 Th...

Embodiment 2

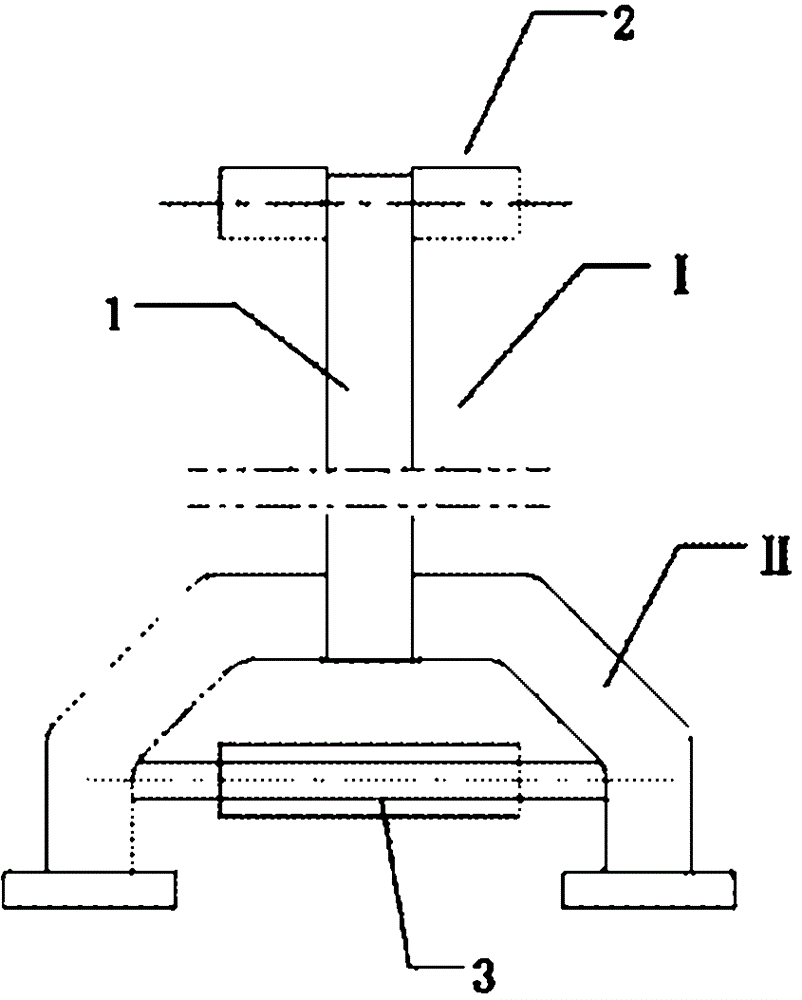

[0047] see figure 2 , except that the following changes, other with embodiment 1.

[0048] The driving wheel 3 is composed of one wheel; the driven wheel 2 is composed of two wheels arranged side by side on the same shaft, and the two wheels are distributed at both ends of the shaft. One end of the support frame 1 is connected on the axle body between the two wheels of the driven wheel 2, and the other end is connected on the body II through the connecting rod 6.

[0049] Saw blade 4 selects chain saw for use. The sawtooth material is made of titanium alloy.

[0050] During work, the output shaft 10 of the driving mechanism is connected with the driving wheel 3 to drive the driving wheel 3 to rotate, thereby driving the driven wheel 2 to rotate through the chain saw wound on the driving wheel 3 and the driven wheel 2 . The sawing of the material is achieved with power applied to the road saw. During the sawing process, the chain saw should be cooled by the cooling device ...

Embodiment 3

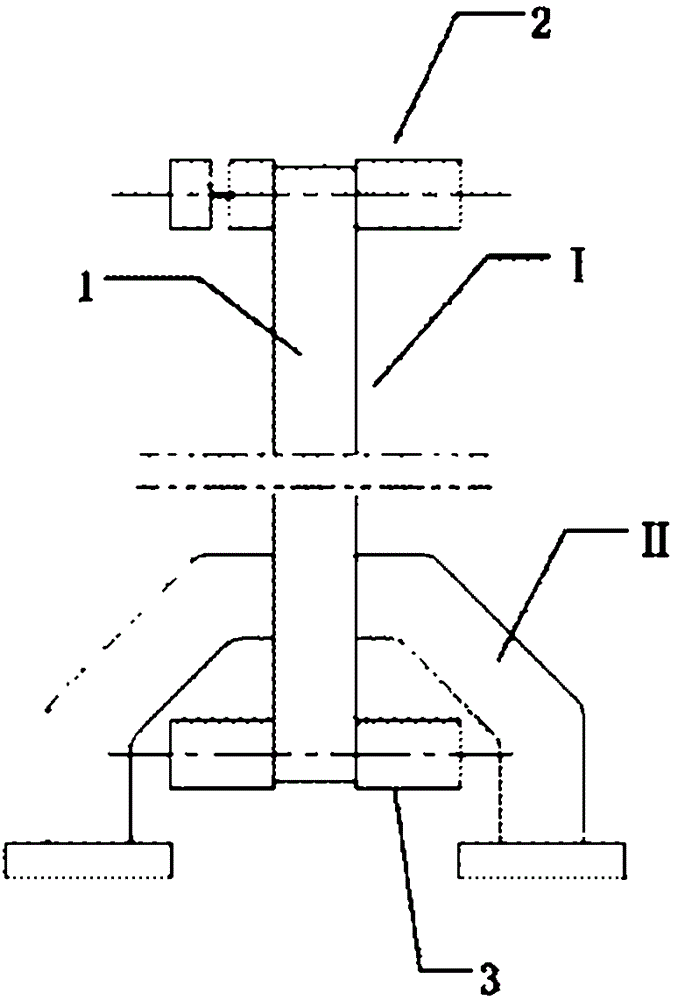

[0052] see image 3 , except that the following changes, other with embodiment 1.

[0053]The driving wheel 3 is composed of two wheels arranged side by side on the same shaft, and the two wheels are distributed at both ends of the shaft; the driven wheel 2 is composed of three wheels arranged on the same shaft, and the two wheels are arranged side by side on the at one end of the axle, and the other wheel is at the other end. One end of the support frame 1 is connected on the shaft body between two parallel wheels of the driven wheel and a wheel, and the other end is connected on the shaft body between the two wheels of the driving wheel.

[0054] Saw blade 4 selects chain saw for use. The sawtooth material is made of high-speed steel.

[0055] During work, the output shaft 10 of the drive mechanism is connected to the driving wheel 3 to drive the driving wheel 3 to rotate, thereby driving the driven wheel 2 to rotate through the chain saw wound around the driving wheel 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com