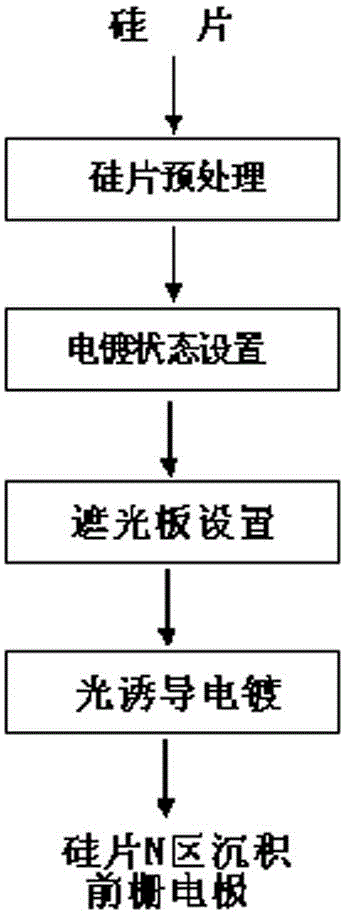

Method and device for preparing solar cell surface gate electrodes by using light induction plating

A light-induced electroplating and solar cell technology, which is applied to circuits, electrical components, semiconductor devices, etc., can solve problems such as unsuitable solar cell technology and difficult light-induced electroplating, and achieve the effect of improving service life and overcoming warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

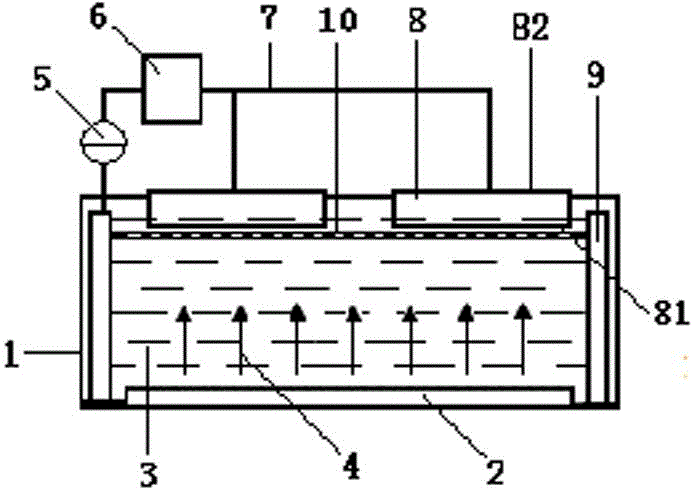

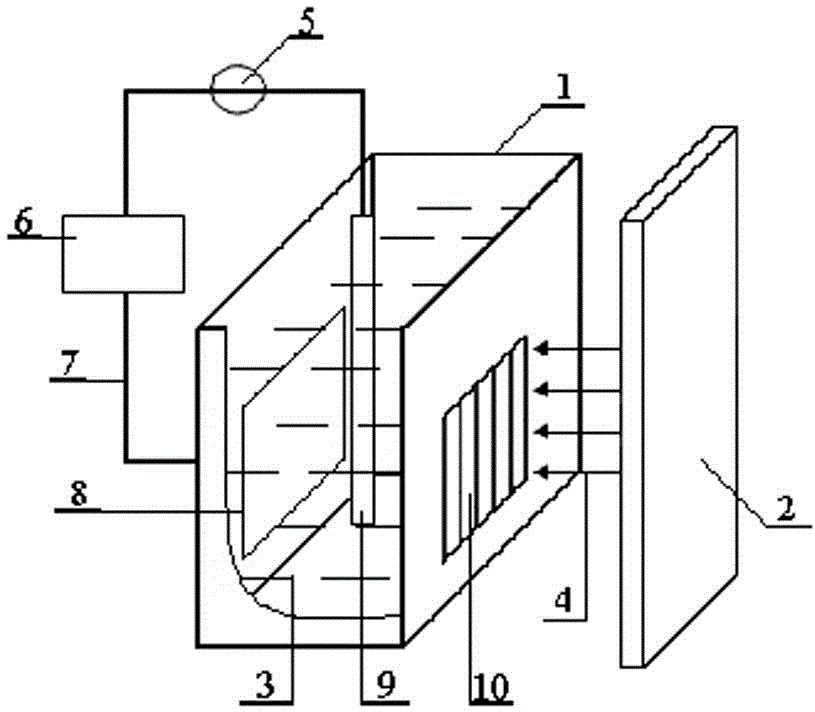

[0042] Inject the prepared 0.01mol / L Co metal ion light-induced electroplating solution into the electroplating pool, and electrically connect the battery silicon chip that has undergone texturing, diffusion, etching, dephosphorization, and back electrode preparation to the electroplating pool and its control circuit In the process, the back electrode of the silicon wafer of the battery is connected to the counter electrode of Co and the power circuit, the position of the silicon wafer of the battery is fixed and the surface of the N area is kept parallel to the surface of the electroplating liquid, and the surface of the N area of the silicon wafer is immersed in the electroplating liquid. Set a grid-shaped shading plate between the surface of the N-zone of the battery silicon wafer and the fluorescent light source and ensure that the surface of the N-zone is parallel, start the light source, and let the light pass through the grid-shaped shading plate to irradiate the surfac...

Embodiment 2

[0044] With the Ni metal ion electroplating solution of 1mol / L as the light-induced electroplating solution, with the Ni electrode as the counter electrode, with natural light as the light source, according to the same process steps as in Example 1, prepare the grid-shaped electrode of the silicon wafer of the battery, and then use the light-induced Electroplating and ordinary electroplating methods, a layer of Cu metal is electroplated on the solar cell grid electrode to strengthen the grid electrode, and the effect is good. After testing, the grid-shaped electrode is firm, the resistivity is lower than that of the grid-shaped electrode prepared by the prior art, the aspect ratio is large, and the effective working area of the battery is large. Compared with the comparison sample of the solar cell prepared by screen printing, the short-circuit current is increased by 5.23% , the open circuit voltage increased by 0.046%, and the fill factor increased by 0.24%.

Embodiment 3

[0046] With the Ni metal ion electroplating solution of 1mol / L as light-induced electroplating solution, with Ni electrode as counter electrode, with natural light as light source, according to the procedure step identical with embodiment 1, prepare battery silicon chip grid-shaped electrode, through detecting grid-shaped The electrode is strong, the resistivity is lower than the grid electrode prepared by the prior art, the aspect ratio is large, and the effective working area of the battery is large. Compared with the comparison sample of the solar cell prepared by screen printing, the short-circuit current is increased by 2.30%, and the open-circuit voltage is increased. 0.046%, and the fill factor increased by 0.18%. This embodiment is in support of the previous embodiments without opting for enhanced plating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com