Process for preparing grapheme modified hard alloy

A technology of graphene modification and cemented carbide, which is applied in the field of cemented carbide preparation, can solve the problems such as carbon content distribution needs to be improved, and achieve the effects of overcoming poor uniformity of addition, reducing sintering defects, and uniform carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

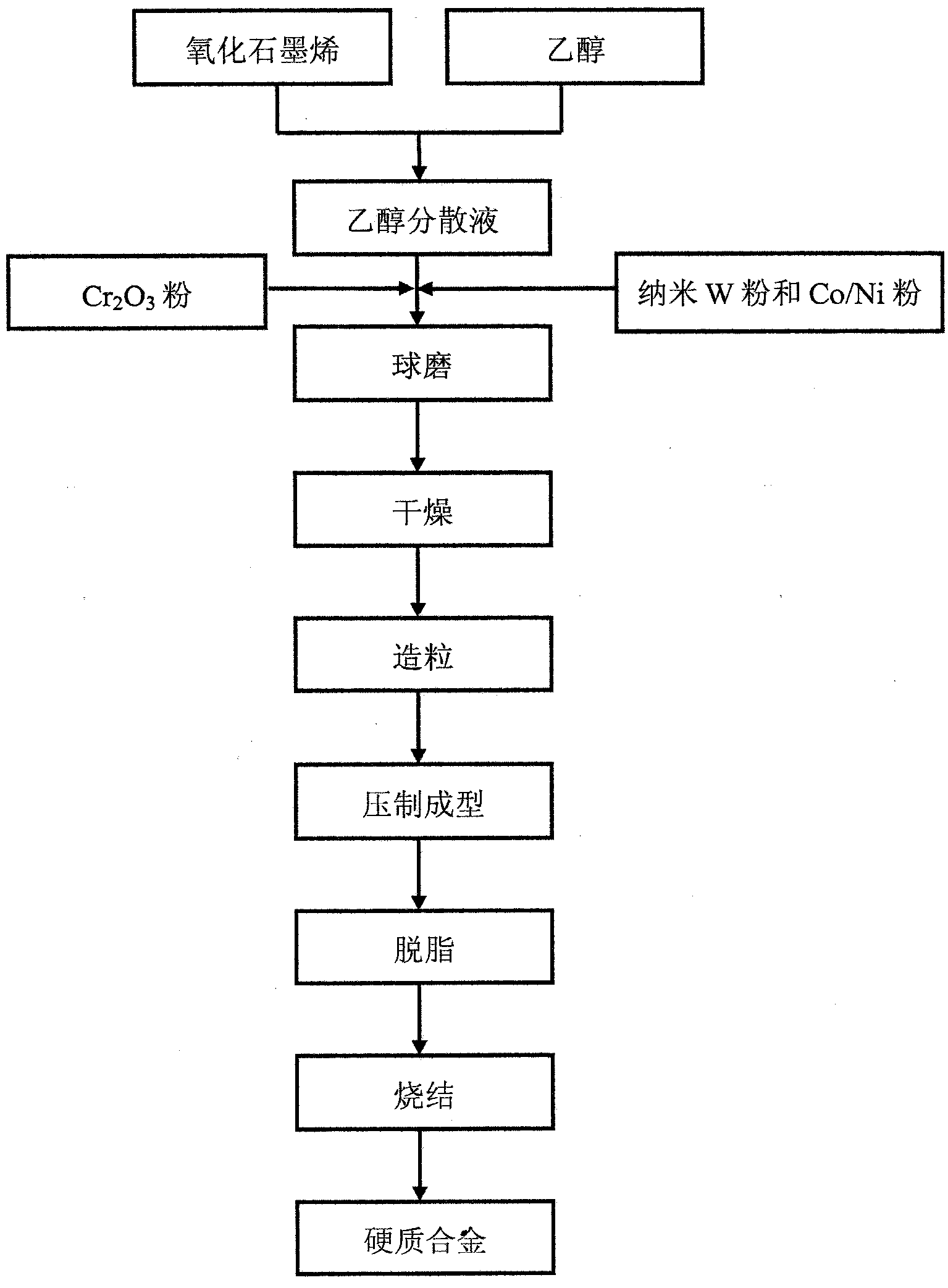

[0027] Further, the efficient preparation method of the graphene-modified cemented carbide may comprise the following steps:

[0028] Step 1, adding the calculated graphene oxide into the ethanol solution to disperse into a uniform suspension;

[0029] Step 2. Mix the calculated ratio of nano-W powder, nano-Co powder or Ni powder with the graphene oxide ethanol dispersion, and add pre-milled Cr 2 o 3 Powder slurry, followed by ball milling to achieve good mixing of graphene with nano metal powder and oxide powder;

[0030] Step 3, powder drying;

[0031] Step 4, granulation;

[0032] Step 5, molding and pressing;

[0033] Step 6. Vacuum degreasing to remove the molding agent;

[0034] Step seven, sintering and forming.

[0035] The graphene oxide added in step 1 can be single-layer, few-layer and multi-layer graphene oxide, and its metering ratio is calculated according to the carbon content required by the W powder carbonization process and sintering process conditions;...

Embodiment 1

[0041] Example 1 The efficient preparation method of the graphene modified cemented carbide is:

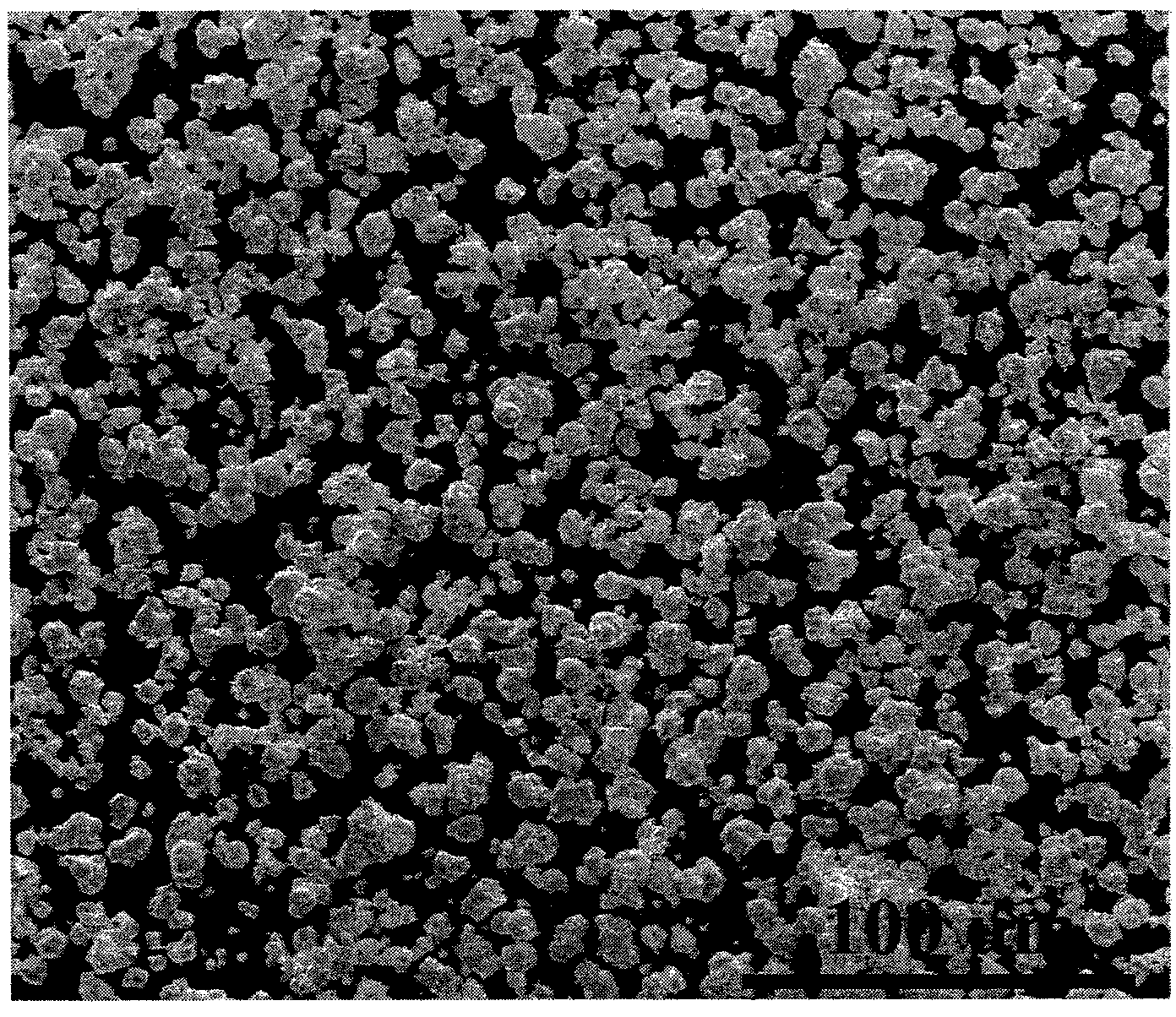

[0042] Graphene oxide with a weight percentage of 5% relative to the cemented carbide raw material is ultrasonically dispersed in ethanol, and then nano-W powder, nano-Co powder, Cr 2 o 3 The powder is added and mixed, ball milled in a planetary ball mill at 200 rpm for 24 hours, then vacuum-dried, mixed with 3wt% polyvinyl alcohol binder relative to the cemented carbide raw material weight percentage, granulated, 350 MPa compression molding, 0.5 degree Raise the temperature to 350 degrees per minute to degrease for 3 hours, and vacuum sinter and densify at 1350 degrees to obtain graphene-modified cemented carbide.

Embodiment 2

[0043] Example 2: The difference between this example and Example 1 is that the amount of graphene added is 1wt%, and its mechanical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com