Method for refining base oil for lubricating oil

A lubricating oil base oil and fine filter technology, applied in the field of refined lubricating oil base oil, can solve the problems of non-recyclable, complicated treatment process, high investment cost, etc., achieve equipment investment cost saving, good adsorption effect, and improve flow rate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

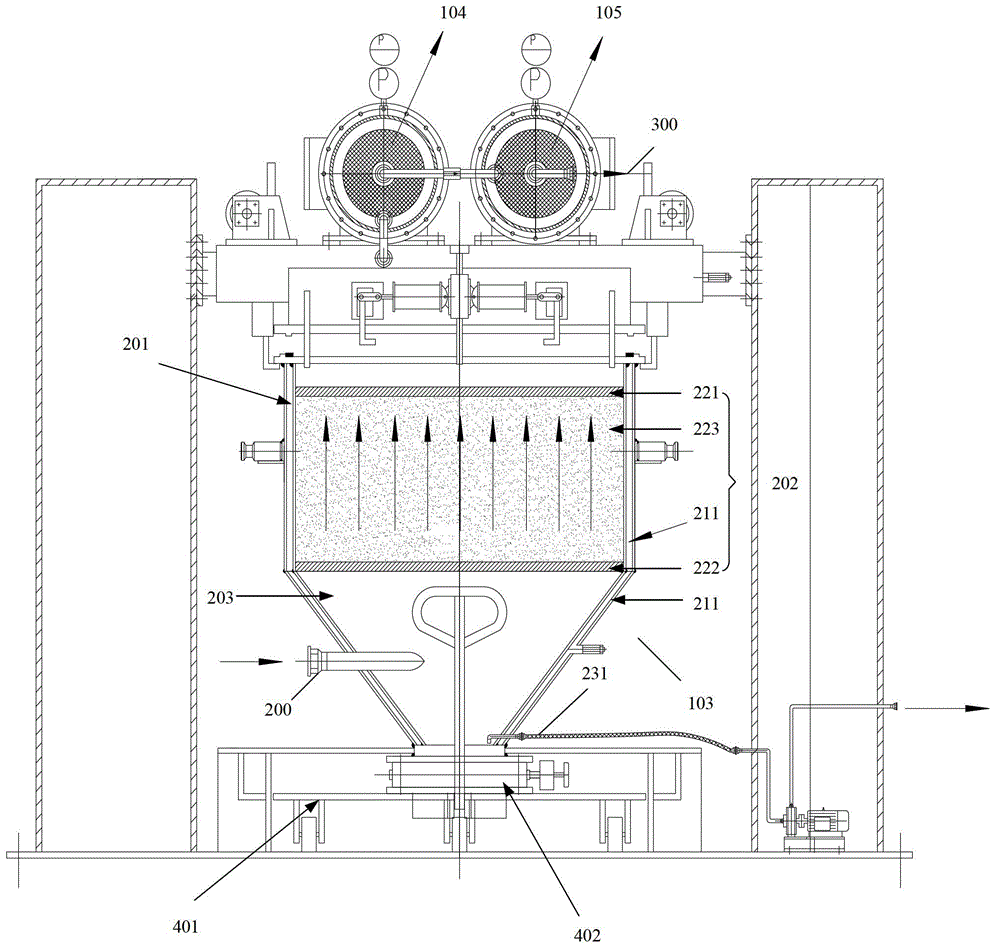

[0027] In the present invention, the lubricating oil base oil is heated to a higher temperature through a two-stage heating method to improve the fluidity of the lubricating oil base oil, and then a fixed bed adsorption method that does not need to provide external force is used. The filtration of the filter can achieve the purpose of fully mixing and adsorbing. Furthermore, by using the non-metallic mineral adsorbent whose main component is silica, not only the adsorption effect is good, but also the amount of solid waste generated is small, and the solid waste can be reused, which greatly saves the cost of solid waste treatment and the cost of the adsorbent.

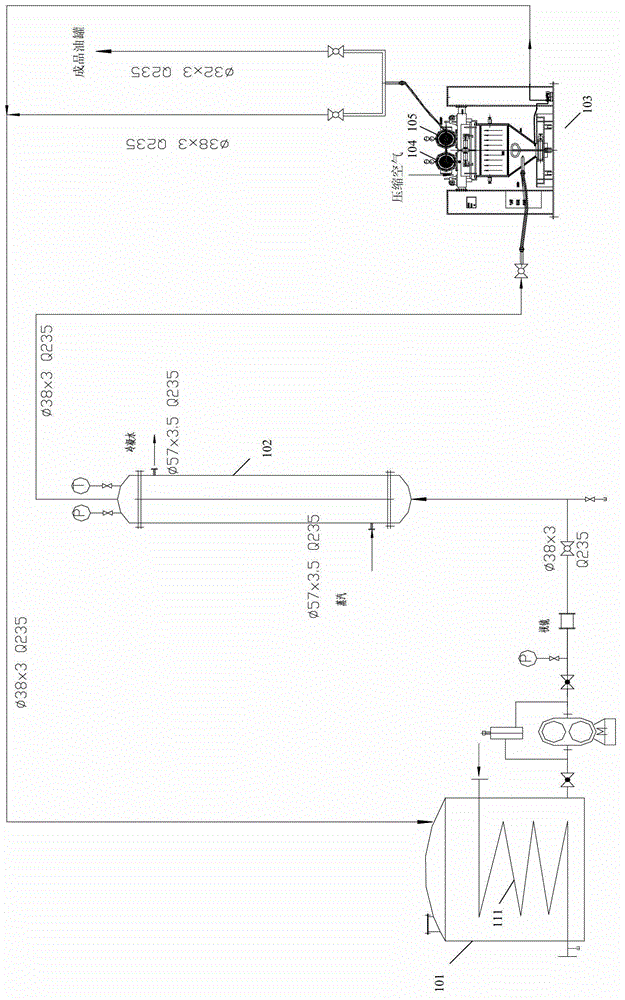

[0028] figure 1 It is a schematic diagram of the method for refining lubricating base oil o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com