Steel structure fireproof paint by taking expanded and vitrified small ball as base material

A technology of expanded vitrified microbeads and fire retardant coatings, which can be used in fire retardant coatings, coatings, etc., to solve problems such as adhesion, poor water resistance, environmental protection, and poor fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

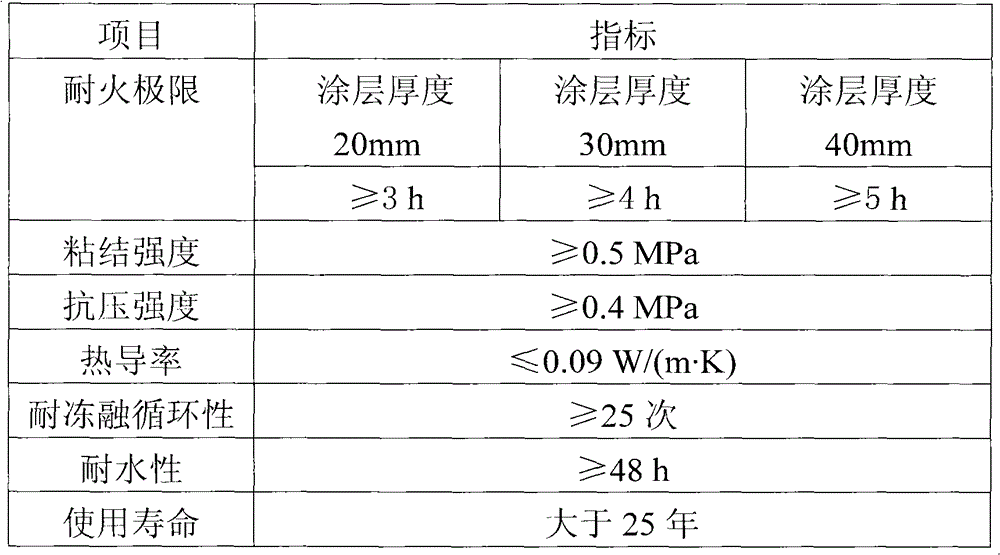

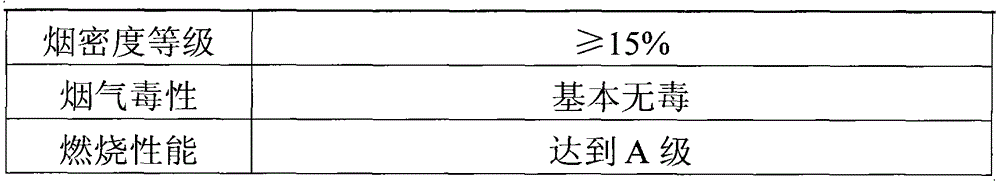

Method used

Image

Examples

Embodiment 1

[0034] 45% cement, 1% calcined kaolin, 5% gypsum, 1% ammonium polyphosphate, 1% organic bentonite; 30% expanded vitrified microbeads; 7% titanium dioxide, 1% zinc oxide, 2% sepiolite powder, talc powder 6%; aluminum silicate fiber 0.5%, leveling agent 0.5%, stir in the mixer and mix evenly;

[0035] Stir the above-mentioned uniformly mixed material and water according to the ratio of 1:1.2 to obtain a viscous fireproof coating. The test results of the prepared steel structure fireproof coating are: bonding strength 0.96MPa, fire resistance limit 3.5h when the thickness is 20mm.

Embodiment 2

[0037] 25% of expanded vitrified microbeads, 1% of calcined kaolin, 1% of gypsum, 1% of ammonium polyphosphate, 2% of organic bentonite, 5% of titanium dioxide, 2% of zinc oxide, 2% of sepiolite powder, 5% of talc powder, 0.5% of aluminum silicate fiber, 45% of water-soluble phenolic resin, 5% of water-soluble acrylic resin, 5% of water-soluble organosiloxane resin; 0.5% of leveling agent is stirred and mixed evenly in the mixer;

[0038] Stir the uniformly mixed material and water according to the ratio of 1:1.2 to obtain a viscous fluid water-soluble fireproof coating for steel structures.

[0039] The test results of the prepared steel structure fireproof coating are: the bonding strength is 0.73MPa, and the fire resistance limit is 3.1h when the thickness is 20mm.

Embodiment 3

[0041] 25% of expanded vitrified microbeads; 1% of calcined kaolin, 1% of gypsum, 1% of ammonium polyphosphate, 3% of organic bentonite, 4% of titanium dioxide, 2% of zinc oxide, 2% of sepiolite powder, 5% of talc powder, 0.5% of aluminum silicate fiber, 45% of solvent-type phenolic resin, 5% of solvent-type acrylic resin, 5% of solvent-type organosiloxane resin; 0.5% of leveling agent is stirred and mixed evenly in the mixer;

[0042] Stir the uniformly mixed material with water and ethanol at a ratio of 1:0.5:0:6 to obtain a viscous fluid solvent-based fireproof coating for steel structures.

[0043] The test results of the prepared steel structure fireproof coating are: the bonding strength is 0.78MPa, and the fire resistance limit is 3.0h when the thickness is 20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fire resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com