Method for extracting and separating cordycepin

A technology of cordycepin and extract solution, which is applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc. It can solve the problems of difficult sample processing, low extraction rate and low purity of cordycepin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]The raw material of the Cordyceps sinensis fruiting body was pulverized by a low-temperature pulverizer (Shanghai Like Polymer Material Co., Ltd.) with liquid nitrogen as the medium at -196°C, and passed through a 200-mesh sieve to obtain a powder; 1:5 mixing, ultrasonic wave extraction under the conditions of ultrasonic frequency (Japan Honda W-115 ultrasonic cleaning machine) 28KHz, output power 200W, extraction time is 30min, and then the centrifuge is separated at a speed of 5000 rpm (high-speed refrigerated centrifuge GL -20B) Filtrate for 15 minutes to obtain the extract, which was analyzed by liquid chromatography, and the mass content of cordycepin was 0.0010%; the extract was mixed with macroporous resin (manufactured by Tianjin Haiguang Chemical Co., Ltd., model NKA Ⅱ), and the temperature was 20°C , the sample volume is 10 times the resin volume, the adsorption flow rate is 3 times the resin BV / hr, and the concentration is 20% (V / V) ethanol as the eluent to elu...

Embodiment 2

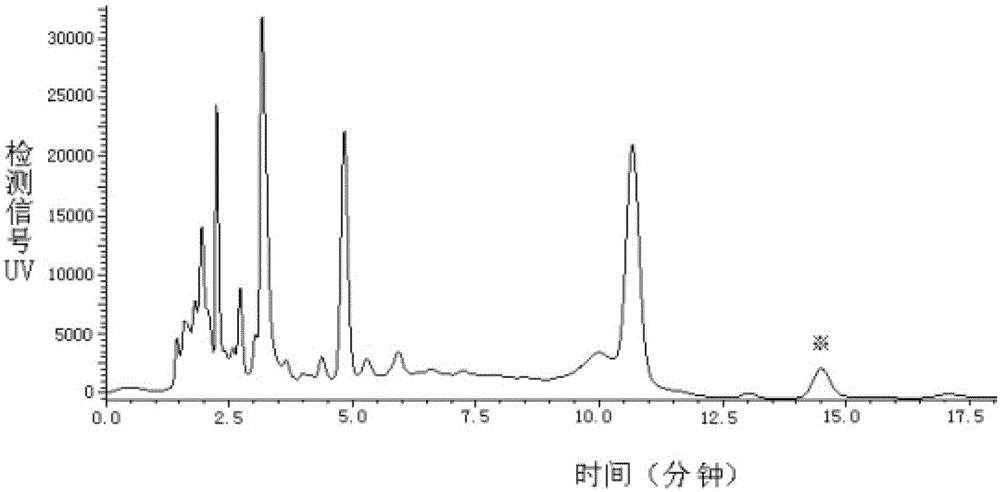

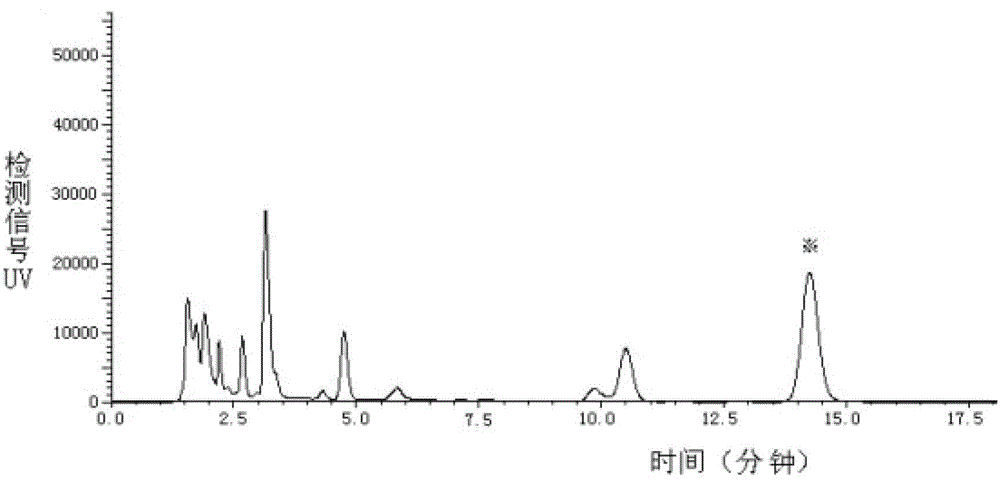

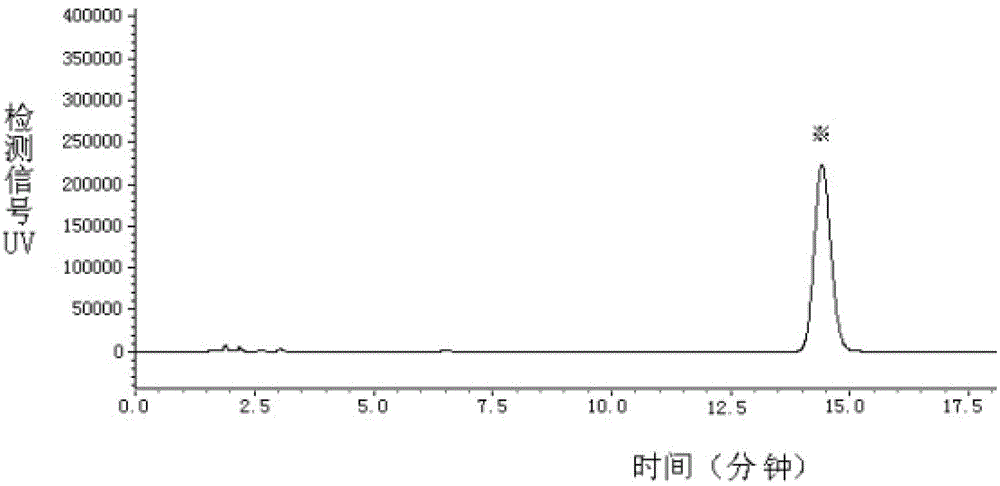

[0056] The raw material of Cordyceps sinensis mycelium is pulverized by a low-temperature pulverizer (Shanghai Like Polymer Material Co., Ltd.) with liquid nitrogen as a medium at -196°C, and passed through a 700-mesh sieve to obtain a powder; 1:10 mixing, ultrasonic wave extraction under the conditions of ultrasonic frequency (Japan Honda W-115 ultrasonic cleaning machine) 30KHz, output power 100W, extraction time is 20min, and then the centrifuge is separated at a speed of 5000 rpm (high-speed refrigerated centrifuge GL -20B) filtered for 15 minutes to obtain the extract, and analyzed by liquid chromatography, the mass content of cordycepin was 0.0012%, such as figure 1 As shown (the peak marked with ※ in the figure represents cordycepin); mix the extract with macroporous resin (manufactured by Tianjin Haiguang Chemical Co., Ltd., model NKAⅡ) to balance, the temperature is 20 ° C, the sample volume is 10 times the volume of the resin, The adsorption flow rate is 1 times the ...

Embodiment 3

[0058] The raw material of the Cordyceps sinensis fruiting body is pulverized by a low-temperature pulverizer (Shanghai Like Polymer Material Co., Ltd.) with liquid nitrogen as the medium at -196°C, and passed through a 500-mesh sieve to obtain a powder; the obtained powder and distilled water are mixed at a weight ratio of 1 : 20 mixing, ultrasonic wave extraction under the conditions of ultrasonic frequency (Japan Honda W-115 ultrasonic cleaning machine) 20KHz, output power 100W, extraction time is 10min, and then the centrifuge is separated at a speed of 5000 rpm (high-speed refrigerated centrifuge GL- 20B) Filtrate for 15 minutes to obtain the extract, which was analyzed by liquid chromatography, and the mass content of cordycepin was 0.0011%; the extract was mixed with macroporous resin (manufactured by Tianjin Haiguang Chemical Co., Ltd., model NKA Ⅱ), and the temperature was 20°C. The loading volume is 10 times the resin volume, the adsorption flow rate is 1.5 times the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com