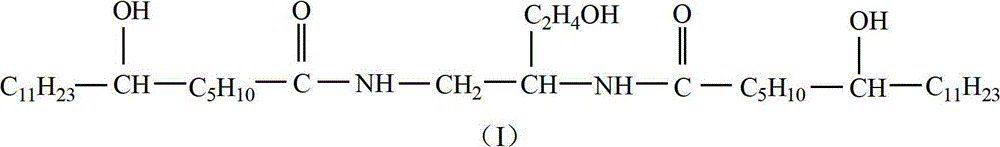

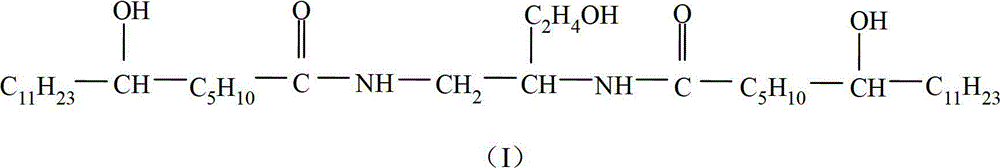

Preparation method for hydroxyethyl dual fatty acid amide

A technology of bis-fatty amide and hydroxyethyl ethylenediamine, which is applied in the field of preparation of hydroxyethyl bis-fatty amide, can solve problems such as the loss of ethylene diamine, achieve the effects of suppressing volatilization, improving utilization rate, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 2 moles of hydroxystearic acid and 1 mole of hydroxyethylethylenediamine are passed into nitrogen under the composite antioxidant of sodium bisulfite and sodium borohydride, the composite catalyst of phosphoric acid, magnesium sulfate and calcium sulfate, the catalyst quality The fraction is 0.3% of the mass fraction of stearic acid. Heat to melt the hydroxystearic acid. When the temperature rises to 80°C, start to add hydroxyethylethylenediamine dropwise, and control the rate of addition so that it is dripped within 0.5 hours. After dripping, quickly raise the temperature to 220°C, react for 2 hours, and complete the high-temperature reaction and dehydration procedure; finally, let the temperature of the material drop to 100°C and discharge, and the finished product has an amine value of ≤5mgKOH / g and an acid value of ≤10mgKOH / g. Using this process for reaction, the yield of the obtained hydroxyethyl bis fatty acid amide is 97%, the color is white, and the melting point...

Embodiment 2

[0040] 2 moles of hydroxystearic acid and 1.1 moles of hydroxyethylethylenediamine are passed into nitrogen under the composite antioxidant of sodium bisulfite and sodium borohydride, the composite catalyst of phosphoric acid, magnesium sulfate and calcium sulfate, the catalyst quality The fraction is 0.4% of the mass fraction of stearic acid. Heat to melt the hydroxystearic acid. When the temperature rises to 90°C, start to add hydroxyethylethylenediamine dropwise, and control the rate of addition so that it is dripped within 0.5 hours. After dropping, the temperature was raised rapidly to 230°C. React for 3 hours to complete the high-temperature reaction and dehydration procedure; finally let the temperature of the material drop to 80°C and discharge to produce a finished product with an amine value of ≤5mgKOH / g and an acid value of ≤10mgKOH / g. Using this process for reaction, the yield of the obtained hydroxyethyl bis fatty acid amide is 97%, the color is white, and the mel...

Embodiment 3

[0042] 2 moles of hydroxystearic acid and 1.2 moles of hydroxyethylethylenediamine are fed into nitrogen under the composite antioxidant of sodium bisulfite and sodium borohydride, the composite catalyst of phosphoric acid, magnesium sulfate and calcium sulfate, the catalyst quality The fraction is 0.3% of the mass fraction of stearic acid. Heat to melt the hydroxystearic acid. When the temperature rises to 100°C, start to add hydroxyethylethylenediamine dropwise, and control the rate of addition so that it is dripped within 0.5 hours. After dripping, the temperature is raised rapidly to 240°C. React for 2.5 hours to complete the high-temperature reaction and dehydration procedure; finally let the temperature of the material drop to 100°C and discharge to produce a finished product with an amine value of ≤5mgKOH / g and an acid value of ≤10mgKOH / g. Using this process for reaction, the yield of the obtained hydroxyethyl bis fatty acid amide is 97%, the color is white, and the melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com