Preparation method for synthesizing tobermorite through using blast furnace slag as raw material

A blast furnace slag and tobermorite technology, which is applied in the removal of silicates, alkaline earth metal silicates and solid wastes, etc., can solve the problems of large plant area, easy explosion in production and large water consumption, etc. The effect of less equipment investment, low production cost and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

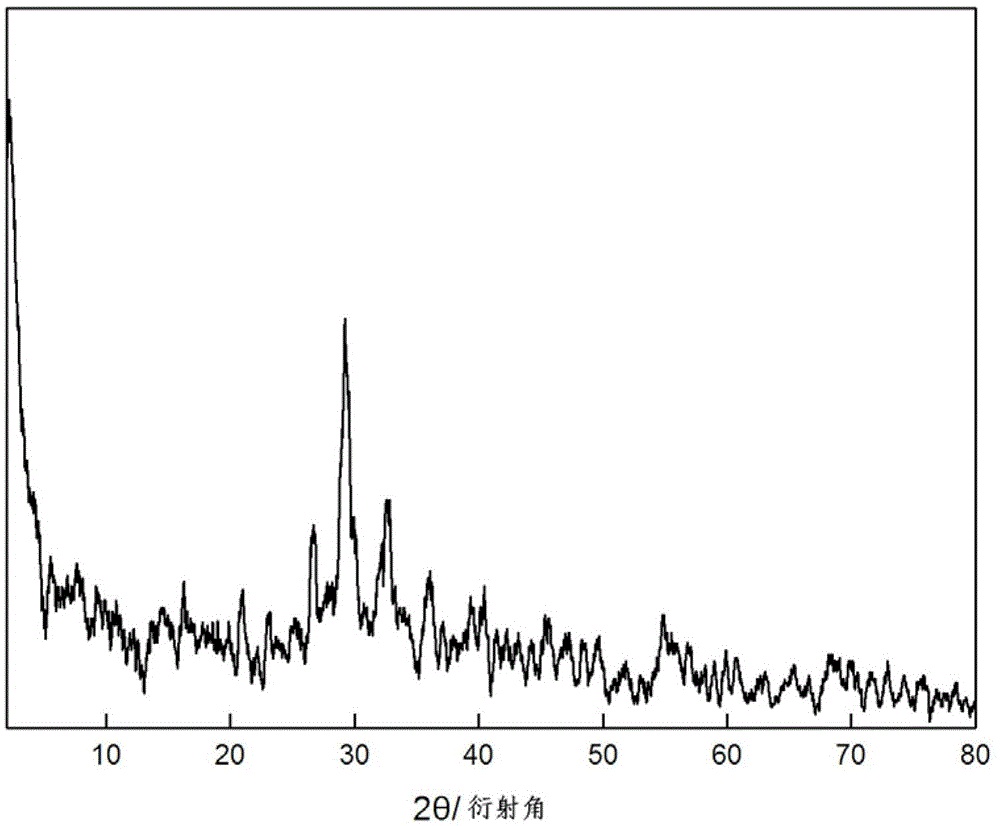

[0023] 1) Crushing and grinding the blast furnace slag to a particle size of 100 mesh, according to mass percentage, blast furnace slag 50%, quicklime 25%, silicon dioxide 25%, control CaO / SiO 2 The molar ratio is 0.8, mix the material and water evenly and pour it into the reaction kettle, the temperature of the reaction kettle is raised, the reaction temperature is kept at 150°C, and the reaction time is 6h. After the reaction is completed, cool and filter to obtain a white solid substance, which is washed and dried to obtain Tobermorite. The spectrum of tobermorite obtained is shown in figure 1 The XRD diffraction pattern.

[0024] 2) The above-mentioned hydrothermally synthesized tobermelite is used to treat high-concentration phosphorus-containing wastewater from pig farms. The phosphorus concentration is 155mg / L, and 4.0g of the above-mentioned hydrothermally-synthesized tobermorite is added to each liter of phosphorus-containing wastewater stone, stirred and reacted fo...

Embodiment 2

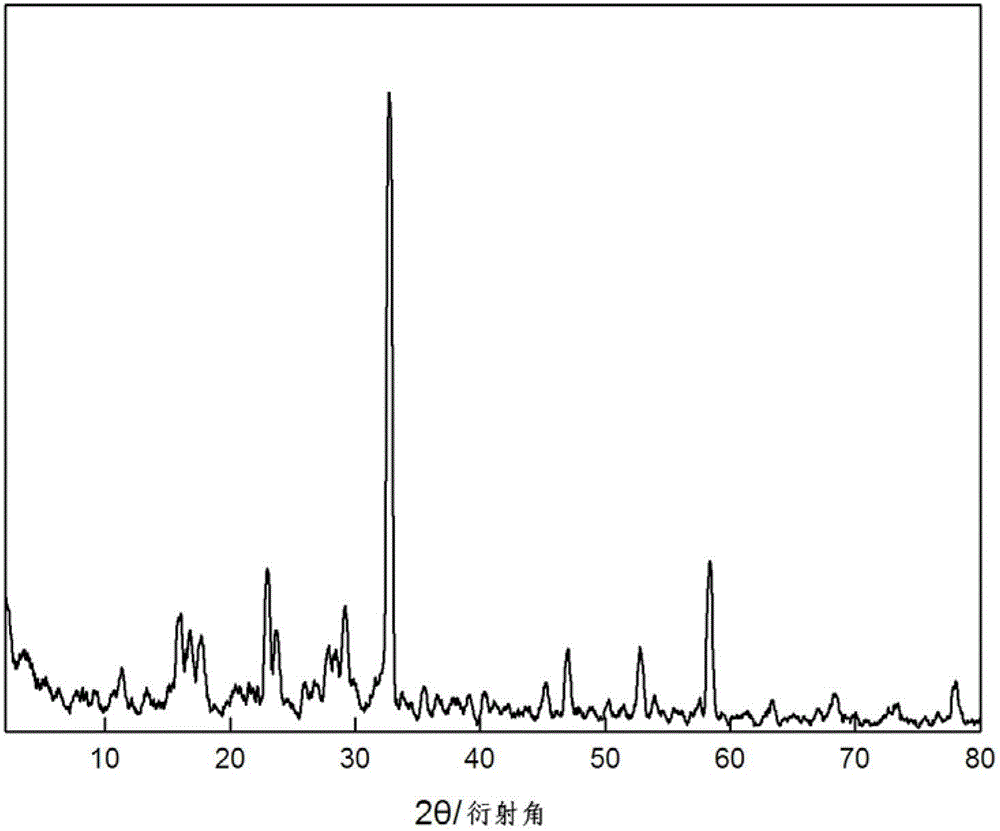

[0026] 1) Crushing and grinding the blast furnace slag to a particle size of 200 mesh, according to mass percentage, blast furnace slag 60%, quicklime 20%, silicon dioxide 20%, control CaO / SiO 2 The molar ratio is 1.0, the material and water are evenly mixed and poured into the reaction kettle, the temperature of the reaction kettle is raised, and the reaction temperature is kept at 180° C., and the reaction time is 8 hours. After the reaction is finished, cool and filter to obtain a white solid, which is washed and dried to obtain tobermorite. The spectrum of tobermorite obtained is shown in figure 2 The XRD diffraction pattern.

[0027] 2) The above hydrothermally synthesized tobermorite is used to treat high-concentration phosphorus-containing wastewater from pig farms. The phosphorus concentration is 155mg / L. Add 3.0g of tobermorite to each liter of phosphorus-containing wastewater, and stir for 1 hour. , the phosphorus content in the effluent wastewater was 0.39 mg / L. ...

Embodiment 3

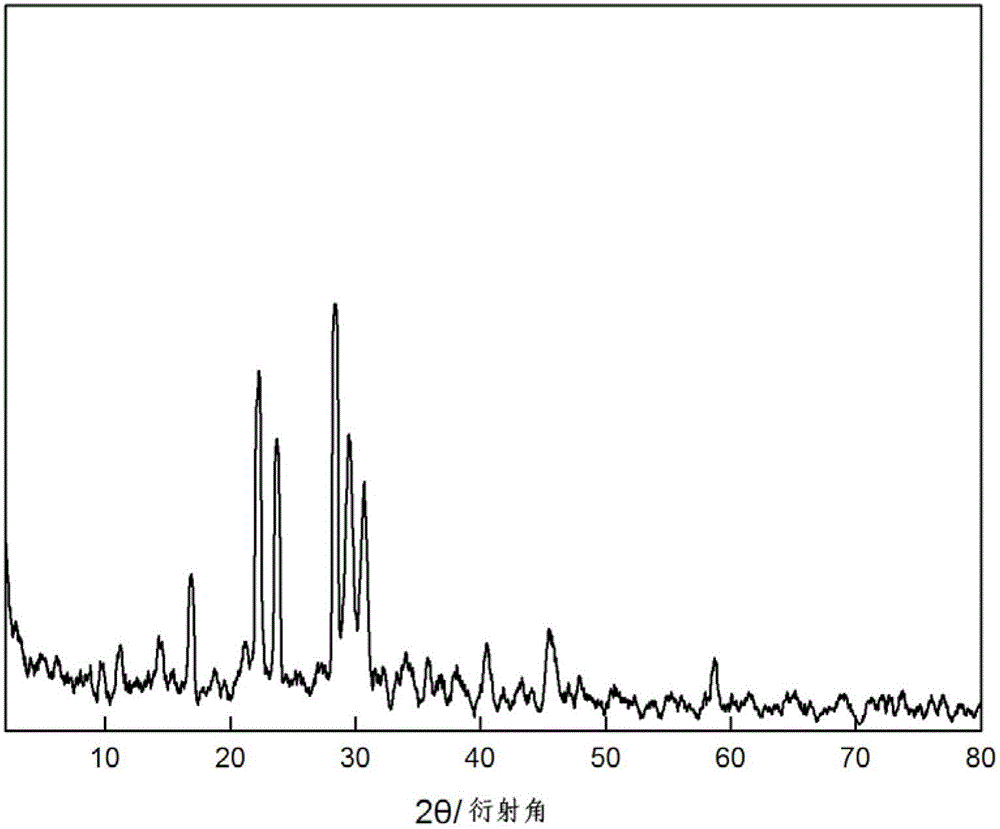

[0029] 1) Crushing and grinding the blast furnace slag to a particle size of 200 mesh, according to mass percentage, blast furnace slag 65%, quicklime 15%, silicon dioxide 20%, control CaO / SiO 2 The molar ratio is 0.8, the material and water are evenly mixed and poured into the reaction kettle, the temperature of the reaction kettle is raised, and the reaction temperature is kept at 200° C., and the reaction time is 10 hours. After the reaction is finished, cool and filter to obtain a white solid, which is washed and dried to obtain tobermorite. The spectrum of tobermorite obtained is shown in image 3 The XRD diffraction pattern.

[0030] 2) Use the above-mentioned hydrothermally synthesized tobermorite to treat domestic phosphorus-containing wastewater. The phosphorus concentration is 15mg / L. Add 1.0g of tobermorite to each liter of phosphorus-containing wastewater, stir for 1 hour, and put it in the effluent wastewater The phosphorus content is 0.15 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com