Method for preparing three-dimensional graphene-carbon nitrogen nanotube composite

A technology of carbon nitrogen nanotubes and composite materials, which is applied in the field of preparation of three-dimensional graphene-carbon nitrogen nanotube composite materials, can solve the problems of complex preparation process, high cost, high cost, etc., and achieve simple preparation process, low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Divide 2×2 cm 2 The nickel foam cleaned ultrasonically with anhydrous ethanol was placed in the middle area of the quartz tube in a horizontal tube furnace, and heated to a reaction temperature of 900 °C at a heating rate of 30 °C / min in a protective atmosphere of hydrogen and argon, and kept for 30 min. , and injected 0.25 ml of ethanol, after the reaction was completed, it was naturally cooled to room temperature under an argon protective atmosphere to obtain a nickel-graphene foam.

Embodiment 2

[0028] Example 2 Divide 2×2 cm 2 The nickel foam cleaned ultrasonically with anhydrous ethanol was placed in the middle area of the quartz tube in a horizontal tube furnace, and heated to a reaction temperature of 1000 °C at a heating rate of 30 °C / min under a protective atmosphere of hydrogen and argon, and kept at a temperature of 30 °C. And inject 0.30 ml of ethanol, after the reaction, naturally cool to room temperature under argon protection atmosphere to obtain nickel-graphene foam.

Embodiment 3

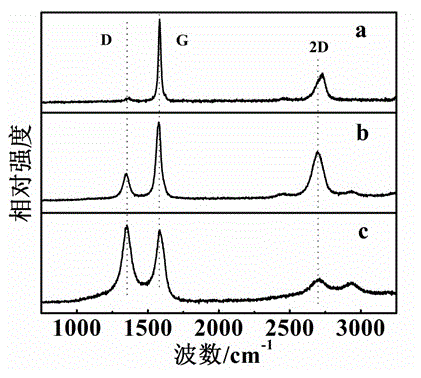

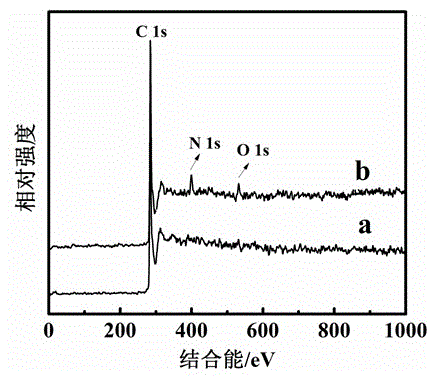

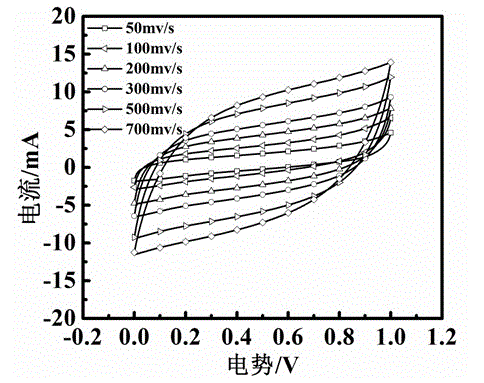

[0029] Example 3 Divide 2×2 cm 2Nickel foam cleaned ultrasonically with anhydrous ethanol was placed in the middle area of the quartz tube in a horizontal tube furnace, and heated to a reaction temperature of 1000 °C at a heating rate of 30 °C / min in a protective atmosphere of hydrogen and argon, and kept for 30 min , and injected 0.25 ml of ethanol, after the reaction was completed, it was naturally cooled to room temperature under an argon protective atmosphere to obtain a nickel / graphene foam. Immerse the nickel-graphene foam in the catalyst solution for 5-30 min, take it out, dry it, place it in the middle area of the quartz tube in a horizontal tube furnace, and heat it at a heating rate of 30 ℃ / min under the protective atmosphere of hydrogen and argon To the reaction temperature of 750 °C, keep it warm for 30 min, and inject 1 ml of ethanol. After the reaction, it is naturally cooled to room temperature under an argon protective atmosphere to obtain a three-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com