Method for producing flame-retardant waterproof decorating plate

A manufacturing method and decorative board technology, applied in the direction of manufacturing tools, wooden veneer joints, chemical instruments and methods, etc., can solve the problems of flammability, achieve good flame retardant and waterproof effects, increase product added value, expand The effect of the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Veneer processing: use a planer to process the wood into thin wood with a thickness of 0.5 mm;

[0024] (2) Drying of veneer: use mesh belt drying method to dry the moisture content of veneer to 12%;

[0025] (3) Glue coating: use a four-roll double-sided glue coating machine to evenly coat the adhesive (mainly composed of polyvinyl alcohol, magnesium oxide, magnesium chloride, industrial flour, water and surfactants) on the upper and lower sides of the glass magnesium board. (4) Aging: aging the glued glass magnesium board for 1.0 hour to evaporate the excess water in the adhesive;

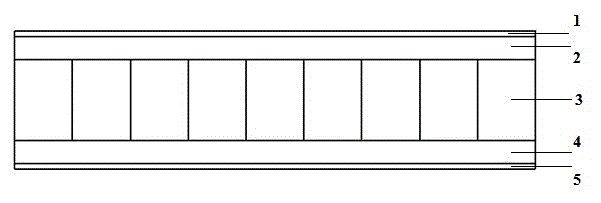

[0026] (5) Blank assembly: Composite assembly of the aged glue-coated glass magnesium board, veneer, and honeycomb aluminum foil with upper and lower surfaces; the slab has a five-layer structure, in which the honeycomb aluminum foil is located in the middle of the slab, and the two sides of the honeycomb aluminum foil Each has a glass magnesium board, and two layers of veneer are res...

Embodiment 2

[0031] (1) Veneer processing: using string cutting machine to process logs into veneer with a thickness of 1.0mm;

[0032] (2) Drying of veneer: Dry the moisture content of veneer to 10% by flat-plate hot pressing drying method;

[0033] (3) Glue coating: use a four-roll double-sided glue coating machine to evenly coat the adhesive (mainly composed of polyvinyl alcohol, magnesium oxide, magnesium chloride, industrial flour, water and surfactants) on the upper and lower sides of the glass magnesium board. surface, the amount of double-sided glue is 600 grams per square meter;

[0034] (4) Aging: aging the glued glass magnesium board for 1.5 hours to evaporate the excess water in the adhesive;

[0035] (5) Blank assembly: Composite assembly of aged glue-coated glass magnesium board, veneer, and honeycomb aluminum foil with upper and lower surfaces. The slab has a 5-layer structure, in which the honeycomb aluminum foil is located in the middle of the slab, and there is a glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com