Non-woven fabric for cable production and preparation method thereof

A non-woven and cable technology, applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of weak flame retardant properties of non-woven fabrics, affecting the service life of cables, and damage to the external surface of cables, etc. The effect of ventilation and heat dissipation, preventing cable failure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A non-woven fabric for cable production, comprising the following components by weight: 35 parts of mixed fiber material, 15 parts of hot-melt adhesive material, 8 parts of flame-retardant additive and 1 part of water-blocking additive.

[0028] In some embodiments, the mixed fiber material is made of polyester, polypropylene and ES materials.

[0029] In some embodiments, the hot-melt adhesive is polyvinyl chloride powder, and the particle diameter of the powder is 200-400um.

[0030] In some embodiments, the flame retardant additive is an inorganic flame retardant.

[0031] In some embodiments, the water-blocking additive is polytetrafluoroethylene waterproof and breathable membrane material.

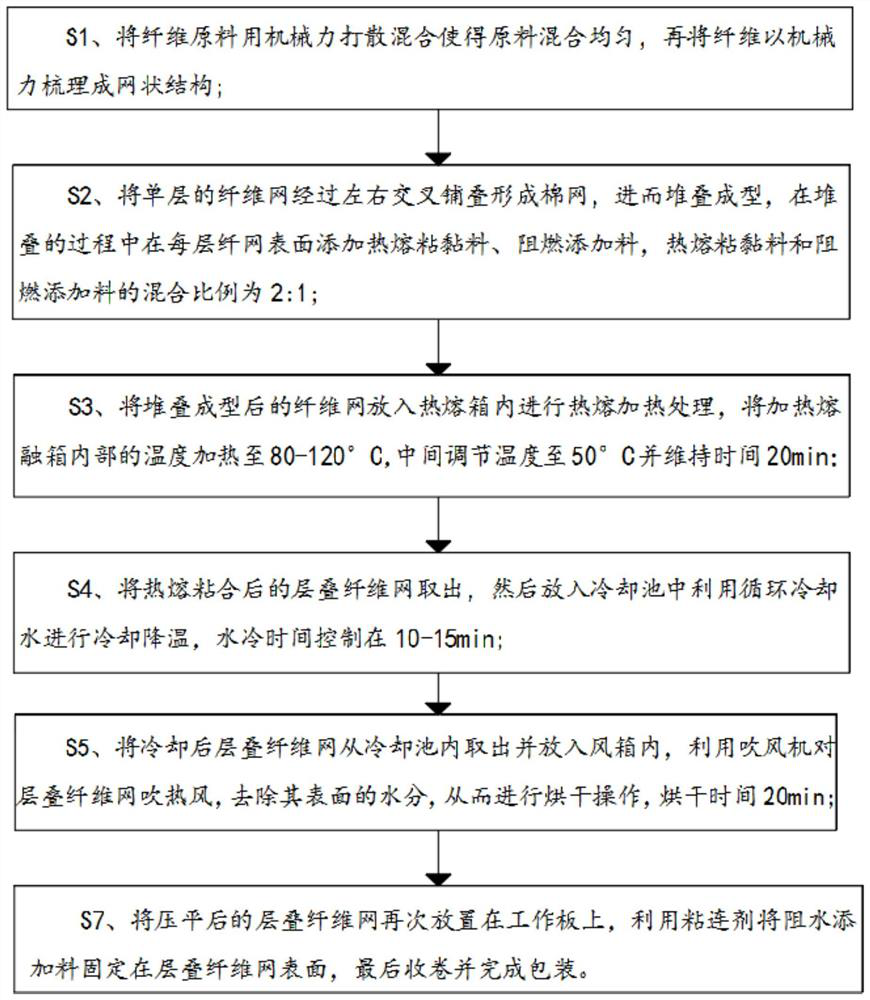

[0032] A preparation method for a non-woven fabric for cable production, comprising the following steps:

[0033] S1. Disperse and mix the fiber raw materials by mechanical force to make the raw materials evenly mixed, and then comb the fibers into a network structure by mech...

Embodiment 2

[0041] A non-woven fabric for cable production, comprising the following components by weight: 45 parts of mixed fiber material, 16 parts of hot-melt adhesive material, 11 parts of flame-retardant additive and 2 parts of water-blocking additive.

[0042] In some embodiments, the mixed fiber material is made of polyester, polypropylene and ES materials.

[0043] In some embodiments, the hot-melt adhesive is polyvinyl chloride powder, and the particle diameter of the powder is 200-400um.

[0044] In some embodiments, the flame retardant additive is an inorganic flame retardant.

[0045] In some embodiments, the water-blocking additive is polytetrafluoroethylene waterproof and breathable membrane material.

[0046] A preparation method for a non-woven fabric for cable production, comprising the following steps:

[0047] S1. Disperse and mix the fiber raw materials by mechanical force to make the raw materials evenly mixed, and then comb the fibers into a network structure by me...

Embodiment 3

[0055] A non-woven fabric for cable production, comprising the following components by weight: 63 parts of mixed fiber material, 16 parts of hot-melt adhesive material, 9 parts of flame-retardant additive and 3 parts of water-blocking additive.

[0056] In some embodiments, the mixed fiber material is made of polyester, polypropylene and ES materials.

[0057] In some embodiments, the hot-melt adhesive is polyvinyl chloride powder, and the particle diameter of the powder is 200-400um.

[0058] In some embodiments, the flame retardant additive is an inorganic flame retardant.

[0059] In some embodiments, the water-blocking additive is polytetrafluoroethylene waterproof and breathable membrane material.

[0060] A preparation method for a non-woven fabric for cable production, comprising the following steps:

[0061] S1. Disperse and mix the fiber raw materials by mechanical force to make the raw materials evenly mixed, and then comb the fibers into a network structure by mecha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com