Automatic black tea fermenting and producing device

A production equipment and technology for black tea, applied in the field of automatic black tea fermentation production equipment, can solve the problems affecting the health, sustainability, stability, rapid development of the black tea industry, being affected by climate change, and labor-intensive, etc., and achieve high production efficiency and operating conditions. Real-time monitoring, the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

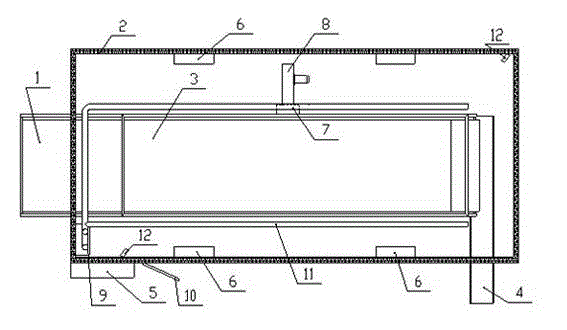

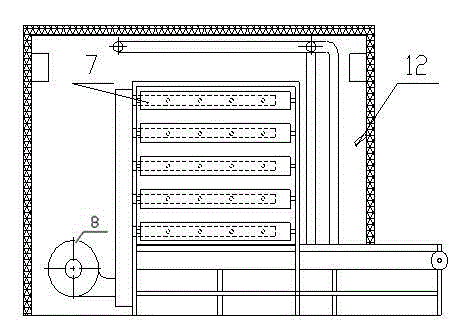

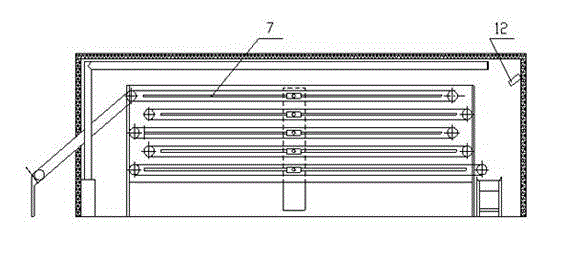

[0015] Now referring to the accompanying drawings, the composition of the automatic black tea fermentation production equipment is further described as follows: the automatic black tea fermentation production equipment includes an intelligent control system 5, a fermentation tank 2, a climbing conveyor belt 1, a turning device 3, a heating and cooling air conditioner 6, a humidification device 9 and a video Monitor head 12.

[0016] Its structure is: the climbing conveyor belt 1 is connected with the overturning device 3, and the end of the overturning device 3 is connected with the output conveyor belt 4; and it is connected with the humidifying device 9, the heating and cooling air conditioner 6, the operation control sensor and the main control cabinet 5, the video surveillance head 12 and multiple Two temperature and humidity sensors are placed in the fermentation tank. The humidifying device 9, the heating and cooling air conditioner 6, the operation control sensor, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com