Method for manufacturing paper board

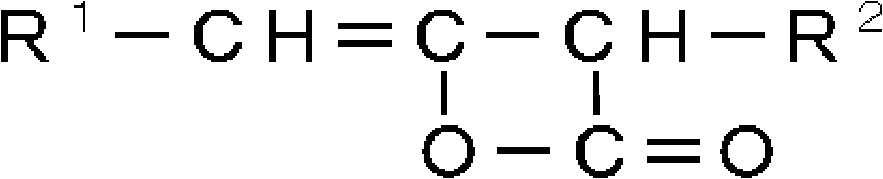

A manufacturing method and paperboard technology, applied in the field of paperboard manufacturing, can solve the problems of unable to obtain dispersion liquid, weak sizing display, unable to obtain sizing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

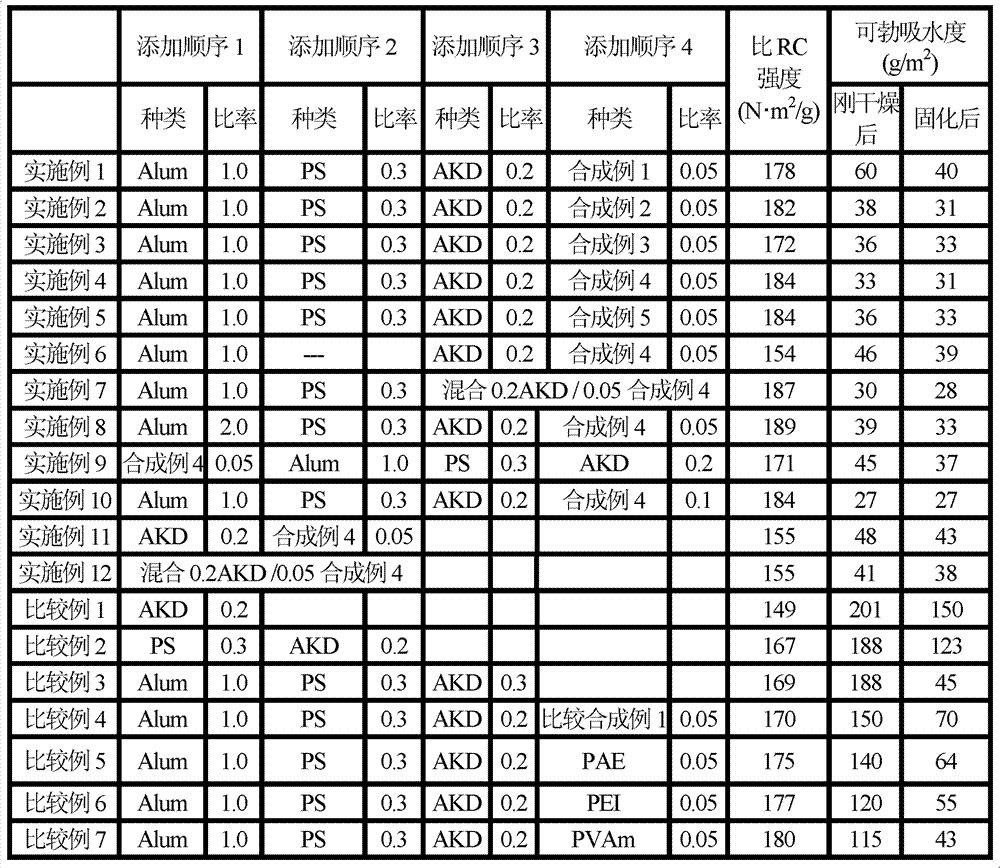

Examples

Embodiment

[0040] Hereinafter, although this invention is concretely demonstrated based on an Example, this invention is not limited to these Examples. In addition, "part" and "%" in an Example and a comparative example are a mass standard unless otherwise indicated.

Synthetic example 1

[0041] Synthesis example 1 (production of diallylamine / acrylamide copolymer)

[0042] After dropping 1330.0 parts of ion-exchanged water and 19.4 parts (0.2 moles) of diallylamine into a reaction device equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen inlet pipe, and a dropping funnel, the pH was adjusted to 7. After blowing nitrogen gas to remove oxygen in the reaction system, it was heated to 70° C., and 3.5 parts of ion-exchanged water and ammonium persulfate were added. Next, 540.4 parts (3.8 mol) of 50% acrylamide aqueous solution was added at 70 degreeC over 2 hours, and it heat-retained at 70 degreeC for 2 hours. After the polymerization, ion-exchanged water was added to obtain an acrylamide copolymer (A) with a non-volatile content of 15.5%, a pH of 3.7, and a viscosity (25° C.) of 2500 mPa·s.

Synthetic example 2~5

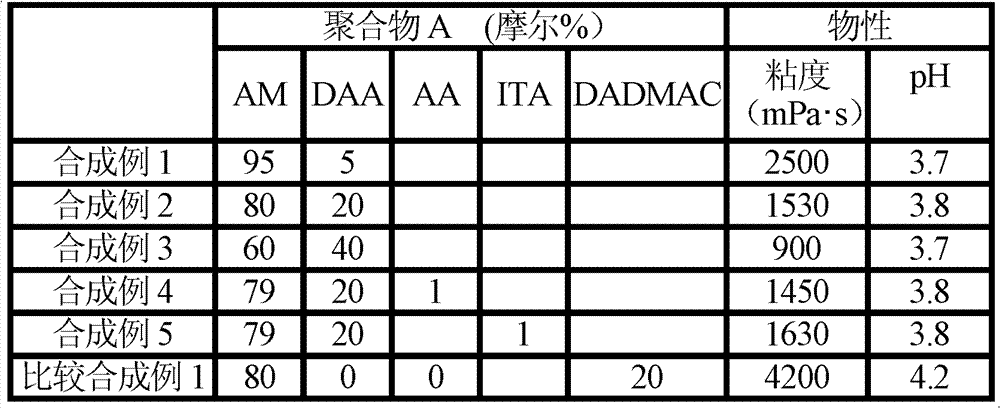

[0043] Synthesis Examples 2-5 and Comparative Synthesis Example 1

[0044] The polymer (A) was obtained by the method similar to the synthesis example 1 except having changed the kind and usage ratio of each component in synthesis example 1 as described in Table 1. In addition, when using acrylic acid and itaconic acid together, after adding these to 50% acrylamide aqueous solution, adding 10% sodium hydroxide aqueous solution, and using it after adjusting pH to 7. The results are shown in Table 1.

[0045] Table 1

[0046]

[0047] *In the table, AM means acrylamide, DAA means diallylamine, AA means acrylic acid, ITA means itaconic acid, and DADMAC means N,N-diallyldimethylammonium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com