Anti-gas-channeling grouting material additive and application method thereof

A technology of grouting materials and admixtures, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of easy flocculation, poor control of cement slurry rheological properties, water loss of latex cement slurry, and thickening time Difficult to control and other problems, to achieve the effect of reducing water loss and improving rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

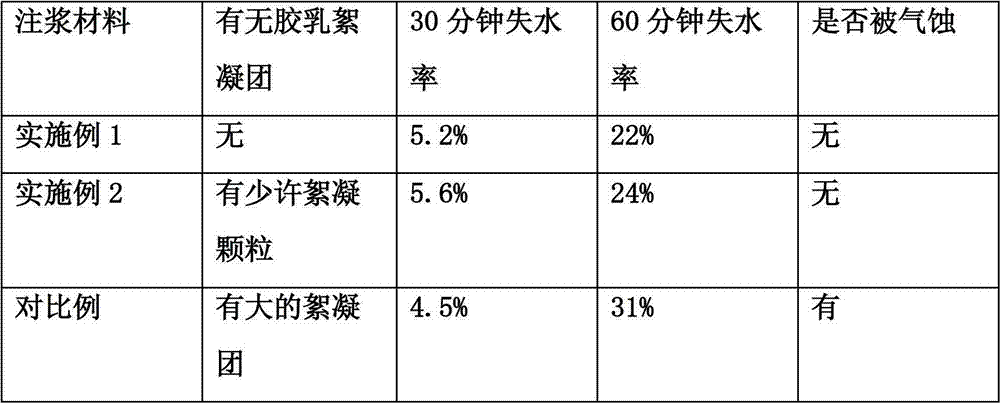

Examples

Embodiment 1

[0010] An admixture for anti-gas channeling grouting material, which consists of 10 parts by weight of sodium lauryl sulfonate, 5 parts of sodium hydroxymethyl carboxylate, cetyl polyoxyethylene ether dimethyl octyl ammonium chloride 3 parts, 1 part of polyacrylamide with a molecular weight of 2000-5000.

[0011] The method of using the admixture: dissolve the admixture with 20 times its mass in deionized water, add an admixture solution of 3% of the latex mass to the latex (the present invention uses commercially available styrene-butadiene latex), and stir evenly to form Latex modifier: Mix Portland cement with twice its mass of water and mix well, add 10% of the mass of Portland cement latex modifier under stirring state, and mix well to be used as grouting material.

Embodiment 2

[0013] An admixture for anti-gas channeling grouting material, which consists of 20 parts by weight of sodium lauryl sulfonate, 12 parts of sodium hydroxymethyl carboxylate, cetyl alcohol polyoxyethylene ether dimethyl octyl ammonium chloride 5 parts, 3 parts of polyacrylamide with a molecular weight of 2000-5000.

[0014] The method of using the admixture: dissolve the admixture with 30 times its mass in deionized water, add an admixture solution with 5% of the latex mass to the latex (the commercially available styrene-butadiene latex used in the present invention), and stir evenly to form a latex Modifier: Mix Portland cement with twice its mass of water and stir well, add latex modifier with 20% of the mass of Portland cement under stirring state, and mix well to be used as grouting material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com