Graphene foam/polymer high-conductivity composite material preparation method and application thereof

A graphene foam, composite material technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of lack of flexibility and elasticity, achieve simplified preparation process, excellent electrical and mechanical properties , high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

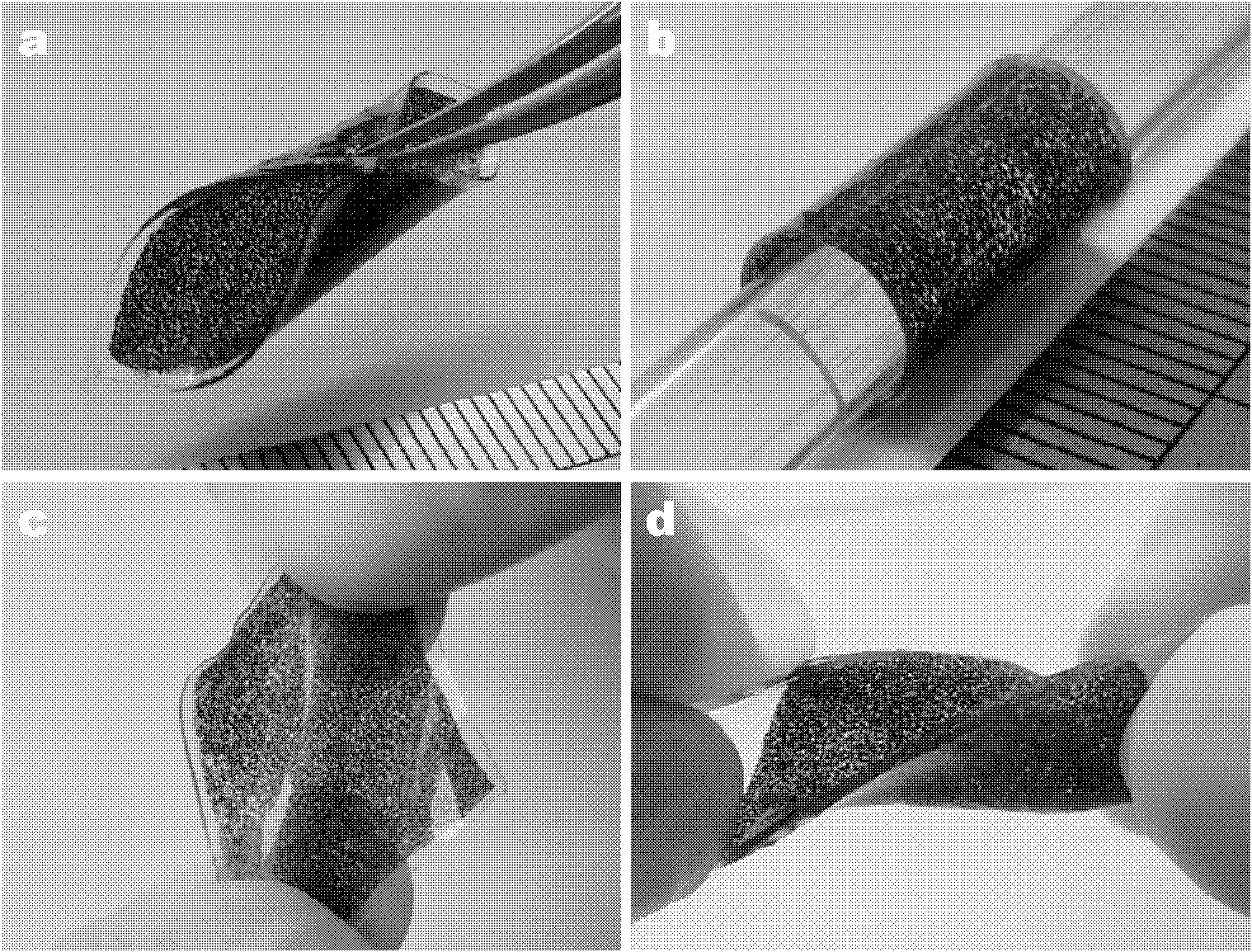

[0029] The present embodiment provides a kind of preparation method of graphene foam / silicone rubber composite material, and concrete scheme comprises the following steps:

[0030] (1) Provide a three-dimensional fully connected graphene foam and a polymer precursor solution

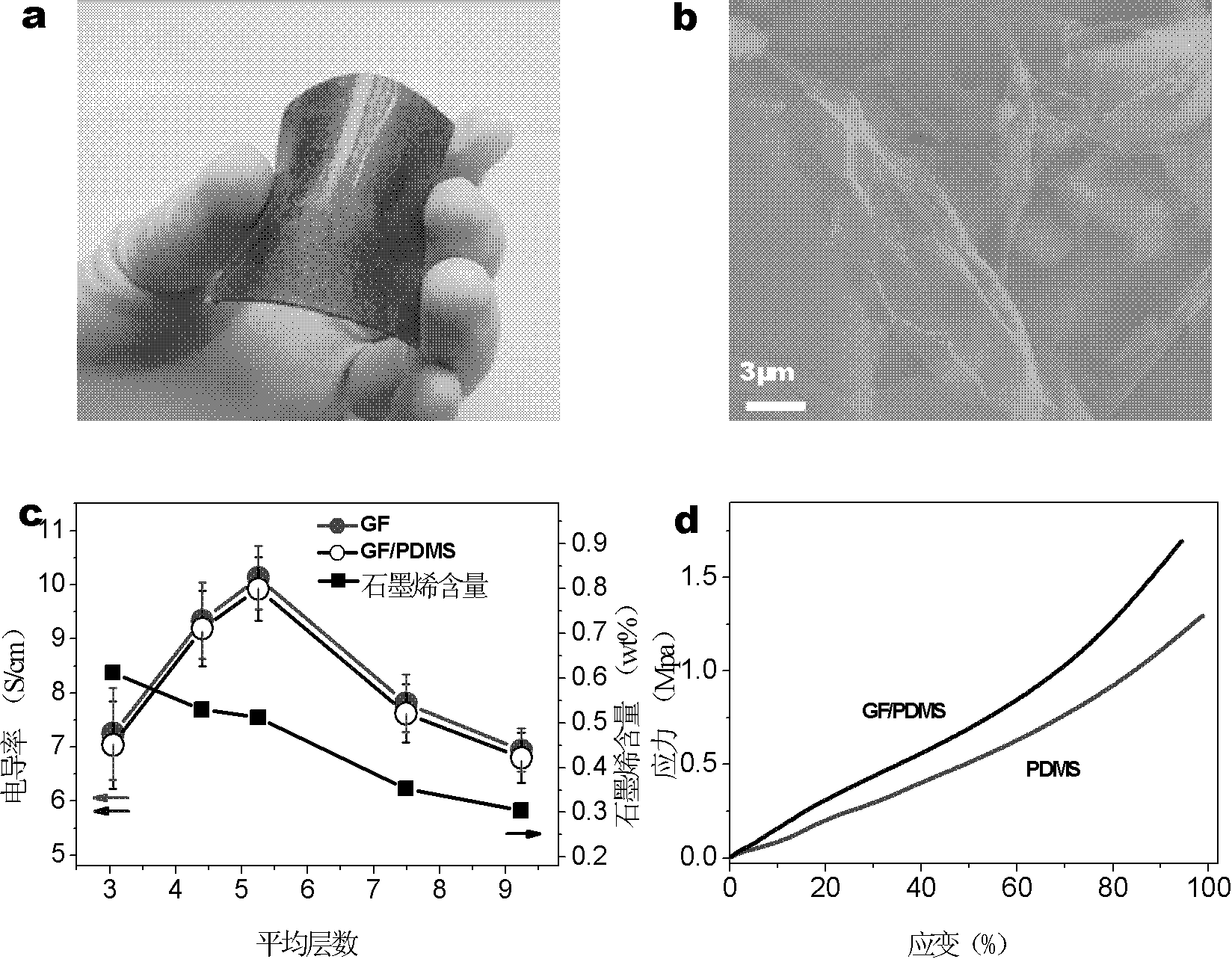

[0031]The method for preparing the graphene foam is a chemical vapor deposition method. This method catalytically cracks the carbon source gas on the surface of the three-dimensional porous metal foam to grow a three-dimensional connected graphene, and then dissolves the metal foam substrate to obtain a porous foam-like graphite. Three-dimensional macroscopic bodies of alkenes. The graphene foam density obtained by adjusting a series of process parameters is 3-5 mg / cm 3 , porosity 99.5~99.8%, specific surface area 300~850m 2 / g, conductivity 7~10S / cm, this embodiment optimizes the density to 5mg / cm 3 , porosity 99.7%, specific surface area 500m 2 / g, conductivity 10S / cm.

[0032] In the present inve...

Embodiment 2

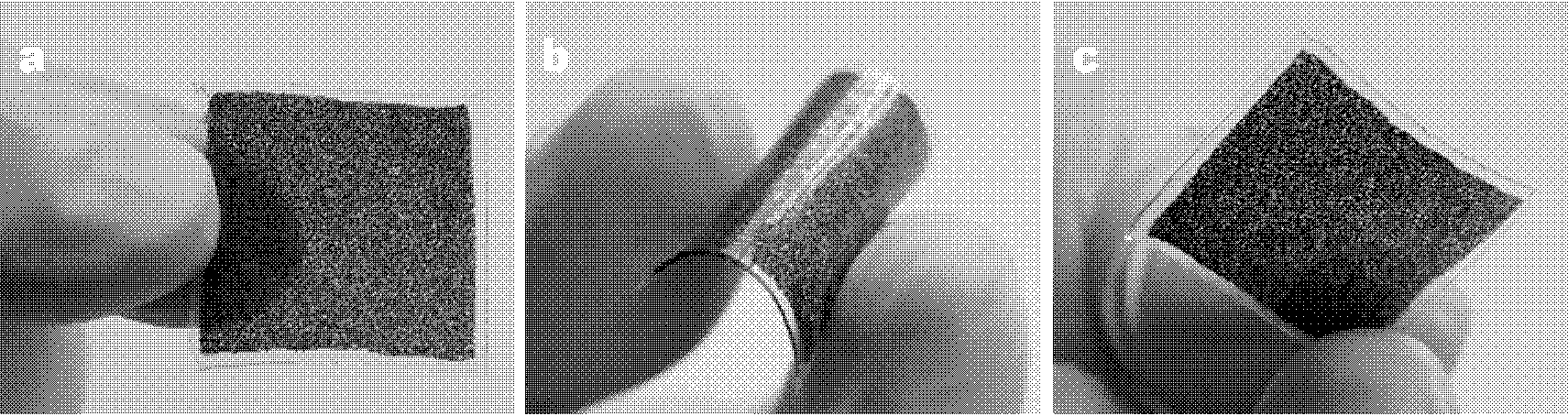

[0040] The present embodiment provides a kind of preparation method of graphene foam / epoxy resin composite material, and specific scheme comprises the following steps:

[0041] (1) Provide a three-dimensional fully connected graphene foam and a polymer precursor solution

[0042] The method for preparing the graphene foam is a chemical vapor deposition method. This method catalytically cracks the carbon source gas on the surface of the three-dimensional porous metal foam to grow a three-dimensional connected graphene, and then dissolves the metal foam substrate to obtain a porous foam-like graphite. Three-dimensional macroscopic bodies of alkenes. The graphene foam density obtained by adjusting a series of process parameters is 3-5 mg / cm 3 , porosity 99.5~99.8%, specific surface area 300~850m 2 / g, conductivity 7~10S / cm, this embodiment optimizes the density to 5mg / cm 3 , porosity 99.7%, specific surface area 500m 2 / g, conductivity 10S / cm.

[0043] In the present inventi...

Embodiment 3

[0050] The present embodiment provides a kind of preparation method of graphene foam / plexiglass composite material, and concrete scheme comprises the following steps:

[0051] (1) Provide a three-dimensional fully connected graphene foam and a polymer precursor solution

[0052] The method for preparing the graphene foam is a chemical vapor deposition method. This method catalytically cracks the carbon source gas on the surface of the three-dimensional porous metal foam to grow a three-dimensional connected graphene, and then dissolves the metal foam substrate to obtain a porous foam-like graphite. Three-dimensional macroscopic bodies of alkenes. The graphene foam density obtained by adjusting a series of process parameters is 3-5 mg / cm 3 , porosity 99.5~99.8%, specific surface area 300~850m 2 / g, conductivity 7~10S / cm, this embodiment optimizes the density to 5mg / cm 3 , porosity 99.7%, specific surface area 500m 2 / g, conductivity 10S / cm.

[0053] In the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com