a modified starch

A technology of modified starch and wet starch, applied in the field of modified starch, can solve the problem of high volatile concentration of organic compounds used, and achieve the effects of reducing the use of chemical reagents, reducing production costs, and reducing the volatile concentration of organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

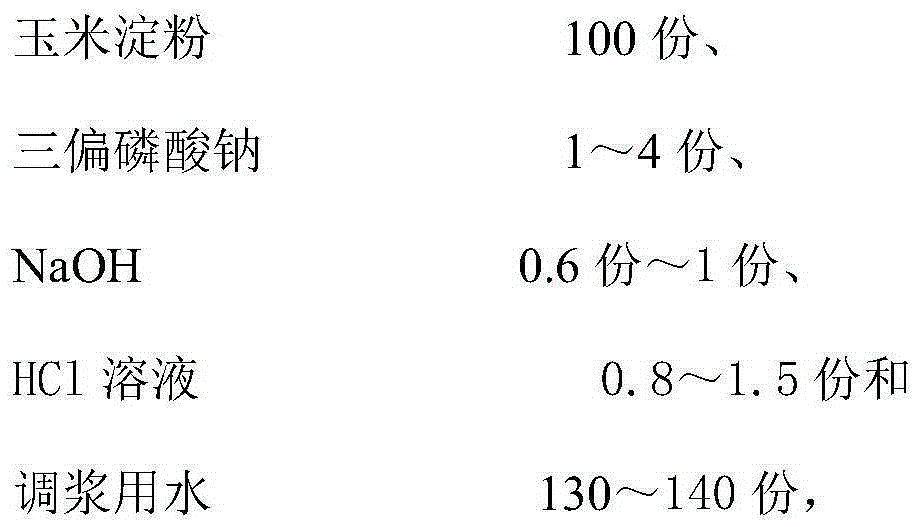

Embodiment 1

[0026] Get 1000g cornstarch and 1300g pulping water, the pulping water hardness (Mg 2+ , Ca 2+ Concentration) below 30. Add 1000g of cornstarch and 1300g of slurry mixing water in a stirring tank, form the slurry of Baume degree 18Be after stirring evenly, add the sodium hydroxide that weight volume ratio concentration is 10% and adjust slurry pH value to 10.8, then Add 10g of sodium trimetaphosphate, carry out cross-linking and esterification reaction at 39.5°C, neutralize the starch slurry to pH 6.0 with hydrochloric acid after the reaction, and then use a disk separator to separate the pH regulator, sodium phosphate and untreated sodium phosphate The sodium trimetaphosphate of reaction is separated, and the conductivity of the starch slurry is controlled at 70us / cm with an online conductivity detector, and then the starch slurry is initially dehydrated with a centrifuge to obtain a water content (percentage by weight) of 37 to 40%. Wet starch lumps, wet starch lumps are d...

Embodiment 2

[0033] Get 1000g cornstarch and 1400g pulping water, the pulping water hardness (Mg 2+ , Ca 2+ Concentration) below 30. Add 1000g of cornstarch and 1400g of slurry mixing water in a stirring tank, form the slurry of Baume degree 22Be after stirring, add the sodium hydroxide that weight volume ratio concentration is 15% and regulate slurry pH value to 11.2, then Add 40g of sodium trimetaphosphate for cross-linking and esterification reaction at 40.5°C. After the reaction, neutralize the starch slurry to about pH 6.5 with hydrochloric acid, and then use a disc separator to separate the pH regulator, sodium phosphate and sodium phosphate produced by the reaction. The unreacted sodium trimetaphosphate is separated, and the conductivity of the starch slurry is controlled at 150us / cm with an online conductivity detector, and then the starch slurry is initially dehydrated with a centrifuge to obtain a water content (percentage by weight) of 37 to 40%. The wet starch lumps are dried...

Embodiment 3

[0040] Get 1000g cornstarch and 1350g pulping water, pulping water hardness (Mg 2+ , Ca 2+ Concentration) below 20. Add 1000g of cornstarch and 1350g of slurry mixing water in a stirring tank, form the slurry of Baume degree 20Be after stirring evenly, add the sodium hydroxide that weight volume ratio concentration is 5% and adjust slurry pH value to 11.0, then Add 30g of sodium trimetaphosphate, cross-linking esterification reaction at 40°C, neutralize the starch slurry to about pH 6.2 with hydrochloric acid after the reaction, and then use the disc separator to separate the pH regulator, sodium phosphate and sodium phosphate produced by the reaction. The unreacted sodium trimetaphosphate is separated, and the conductivity of the starch slurry is controlled at 100us / cm with an online conductivity detector, and then the starch slurry is initially dehydrated with a centrifuge to obtain a water content (percentage by weight) of 37 to 40%. The wet starch lumps are dried in a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com