Apparatus for reducing arene extraction solvent sulfolane, and application thereof

A technology for the extraction and application of aromatics, which is applied in the direction of organic chemistry, can solve the problems of low operating cost, unresolved defects, degraded sulfolane energy consumption and high power consumption, so as to improve economic benefits, strong anti-organic pollution ability, eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

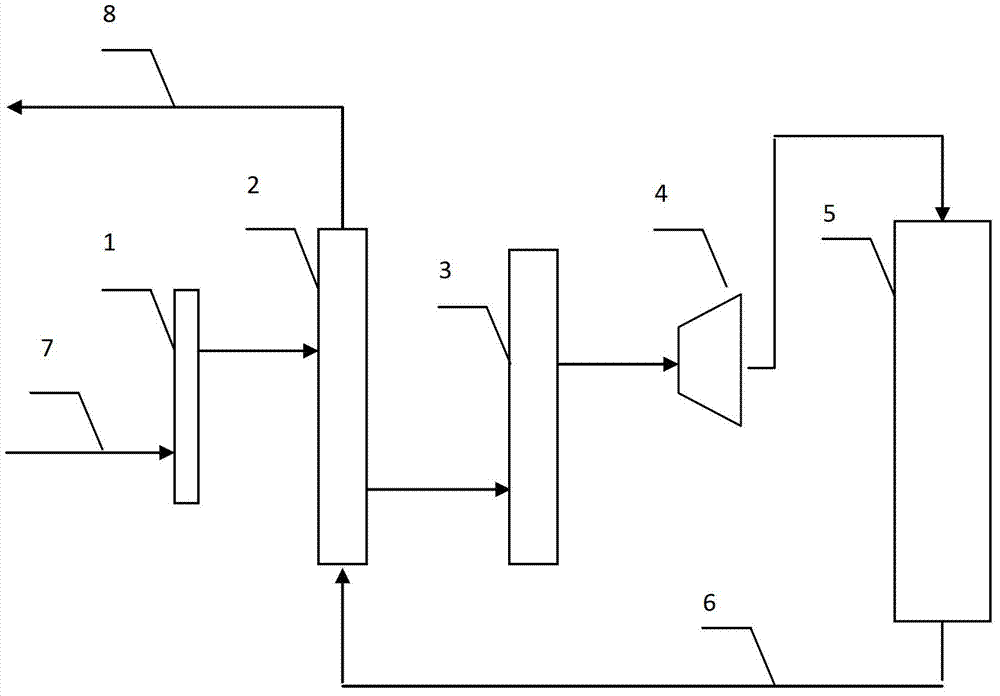

Method used

Image

Examples

Embodiment 1

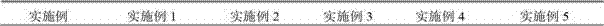

[0033] The volumetric space velocity of sulfolane entering the resin tower is controlled by a flow meter to be 1.5h -1 , adjust the flow of cooling water in the cooler, and control the temperature of the poor sulfolane solvent entering the resin tower to 60°C. The sulfolane poor solvent entering the resin exchange tower pH4.3, Cl - Content 5.9mg / kg. Sampling the sulfolane poor solvent flowing out of the resin tower, analyzing Cl - Content, pH value, the results are shown in Table 2.

Embodiment 2

[0035] The volume space velocity of sulfolane entering the resin tower is controlled by a flow meter to be 9.0h -1 , adjust the flow of cooling water in the cooler, and control the temperature of the poor sulfolane solvent entering the resin tower to 55°C. The sulfolane poor solvent entering the resin exchange tower pH4.3, Cl - content of 5.9mg / kg, the sulfolane poor solvent flowing out of the resin tower is sampled, and the Cl -- Content, pH value, the results are shown in Table 2.

Embodiment 3

[0037] The volumetric space velocity of sulfolane entering the resin tower is controlled by a flow meter to be 4.5h -1 , adjust the flow of cooling water in the cooler, and control the temperature of the poor sulfolane solvent entering the resin tower to 50°C. The sulfolane poor solvent entering the resin exchange tower pH4.3, Cl - Content 5.9mg / kg. Sampling the sulfolane poor solvent flowing out of the resin tower, and analyzing its Cl - Content, pH value, the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com