Method for machining cutter and dedicated mold

A processing method and mold technology, applied in the field of forging dies and tool forging dies, can solve the problems of uneven overall strength of the tool, easy bending of the forming tool, high processing cost, and achieve convenient workpiece fixation, improved yield, and uniform hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A processing method for a gear shaping cutter, which comprises cutting a section of high-speed tool steel bar, the volume of which is greater than 3-5% of the volume of the gear shaping cutter to be processed, and its diameter is the same as that of the shaft of the forming gear shaping cutter. The diameter is the same. It is heated in a high-temperature furnace to a temperature suitable for forging, and then put into a special mold cavity with the same shape as the finished gear shaper for forging and pressing. After demoulding, it is milled and ground.

[0020] The above method is suitable for the processing of various metal cutting tools, but the cavities and models of the special molds are different.

Embodiment 2

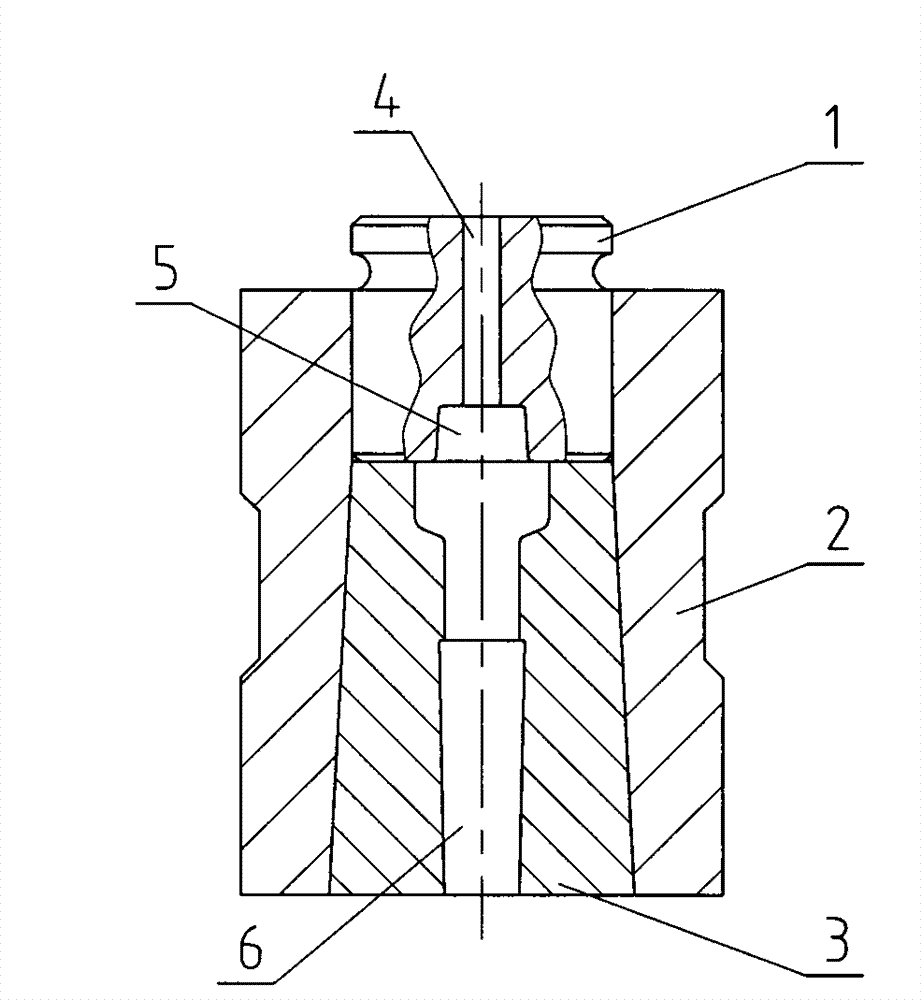

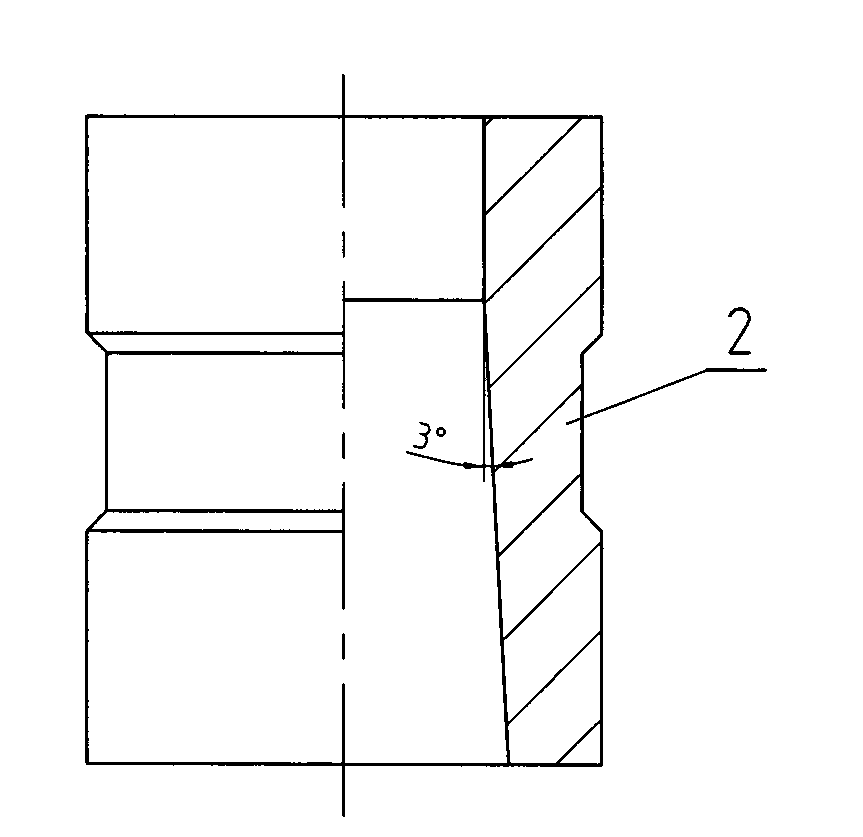

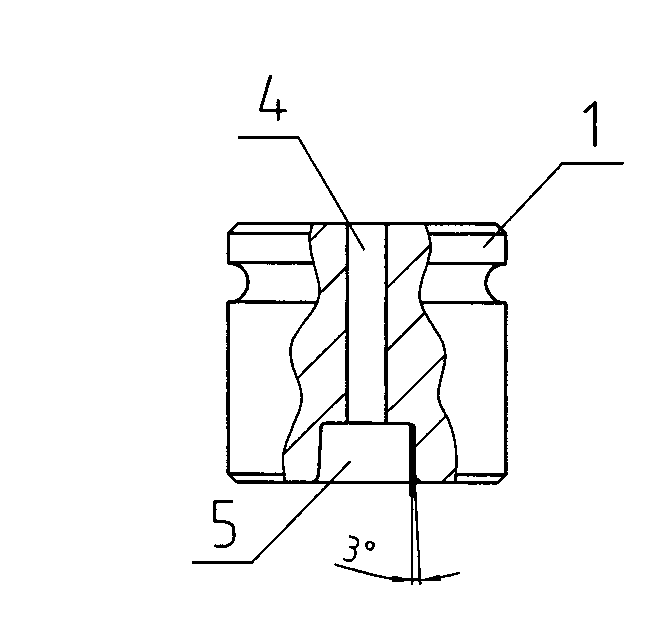

[0022] Such as Figure 1-5 As shown, the special mold used in the method of the present invention is made up of upper mold 1, lower mold 2 and die sleeve 3. The shape of the upper mold 1 is cylindrical, and the upper mold cavity 5 is conical with a small top and a large bottom, with a taper of 3°, or any angle within 2° to 5°; the lower mold cavity 6 and the main body shape of the forming tool The same, its shape is a conical shape with a small top and a big bottom, with a taper of 3°, or any angle within 2° to 5°; the inner wall of the mold sleeve 3 is matched with the outer wall of the upper mold 1 and the lower mold 2. The mold cavity 5 communicates with the exhaust hole 4, and the upper mold 1 can freely slide up and down on the upper section of the mold sleeve 3. This kind of mold is easy to fit and withdraw from the mold. During forging, the upper mold can be moved down conveniently. During the forging process of slightly thicker workpieces, the lower mold gradually mov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com