Catalyst used for preparing 1,3-propylene glycol through glycerin hydrogenolysis, preparation method thereof, and application thereof

A glycerol hydrogenolysis and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, preparation of eliminating hydroxyl groups, etc., can solve the problem of inability to convert glycerol on a large scale, low product concentration, and product separation problems such as rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

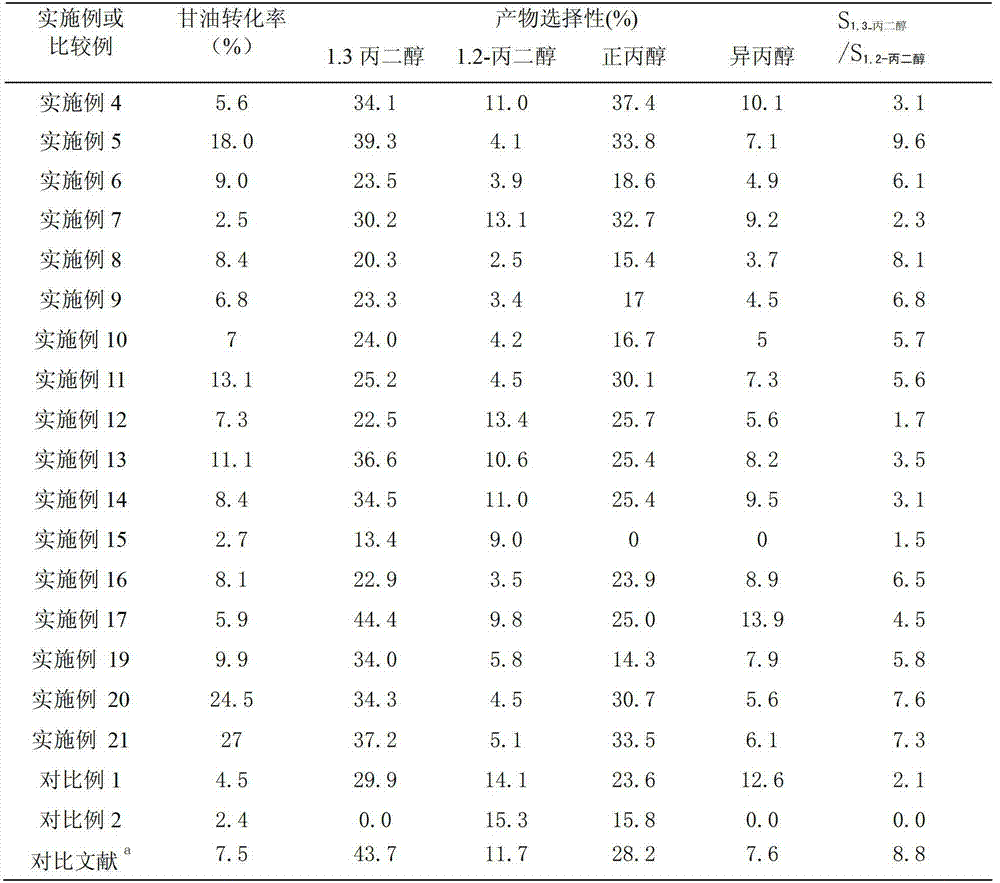

Examples

Embodiment 1

[0020] Preparation of mesoporous tungsten oxide and ammonium metatungstate calcined tungsten oxide:

[0021] 0.5 g of P123 (EO 20 PO 70 EO 20 ) was dissolved in 5 g of n-propanol, and after P123 was completely dissolved, 1.78 g of tungsten precursor WCl was added 6 (P 123 : Solvent: WCl 6 The mass ratio is 0.5:4:1.78), stirred at room temperature for 4 hours, the obtained sol was coated on a glass plate, placed in an oven at 60°C for 5 days, and the obtained tungsten oxide precursor was calcined at 500°C for 1 hour to obtain mesoporous Tungsten oxide support, labeled M-WO 3 .

[0022] Calcinate ammonium metatungstate at 500°C in an air atmosphere for 4 hours, the heating rate is 1°C / min, and the air flow rate is 40ml / min to obtain tungsten oxide, which is marked as A-WO 3 .

[0023] Commercial tungsten oxide, labeled C-WO, was purchased from Aladdin reagents 3

[0024] The pore structure parameters of the obtained tungsten oxide are shown in Table 1.

[0025] ...

Embodiment 2

[0028] Preparation of Pt / WO by Impregnation Method 3 catalyst

[0029] Weigh 1.0g of the tungsten oxide carrier prepared in Example 1, immerse the tungsten oxide carrier in 0.5ml of aqueous solution containing 0.054g of chloroplatinic acid, let stand at 20°C for 12 hours, and then pass through 60°C and 120°C oven After drying for 6 hours, the catalyst was calcined in an air atmosphere. The specific process was as follows: from 20°C to 400°C at a rate of 10°C / min and maintained for 1 hour, the air flow rate was 40ml / min. The catalyzer after this calcining is carried out temperature-programmed reduction in hydrogen, and concrete reaction process is: rise to 300 ℃ and keep 1 hour by room temperature with 10 ℃ / min heating rate and keep 1 hour, and hydrogen flow rate is 60ml / min. The theoretical loading of platinum in the prepared catalyst is 2wt%, and the catalyst is marked as 2Pt / M-WO 3 (here M-WO 3 example).

Embodiment 3

[0031] Catalyst performance evaluation of glycerin catalytic conversion:

[0032] The catalytic reaction was carried out in a stainless steel autoclave made by Parr (100ml), and 1g of catalyst was weighed, and 40ml of glycerol was used as a 10wt% aqueous solution. Replace the air in the reactor with hydrogen three times, and then fill with 5.5MPa hydrogen. Heat up to 180 DEG C and react for 12 hours and then cool down. After the product is filtered or centrifuged, the pre-reaction and post-reaction liquids are diluted ten times with methanol and then analyzed by GC.

[0033] The calculation formulas of the conversion rate of glycerol and the selectivity of product are as follows respectively:

[0034] The conversion rate of glycerol (%) = (the number of moles of glycerol before the reaction - the number of moles of glycerol after the reaction) / the number of moles of glycerol before the reaction × 100%.

[0035]Selectivity of 1,3-propanediol or 1,2-propanediol (%)=(moles of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com