Microwave-assisted extraction process for mongolian milkvetch root saponin and mongolian milkvetch root polysaccharide

A technology of astragalus saponins and astragalus polysaccharides, which is applied to medical preparations containing active ingredients, plant raw materials, plant/algae/fungus/moss components, etc., to achieve the effects of increased yield, improved extraction rate, and improved utilization of effective substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

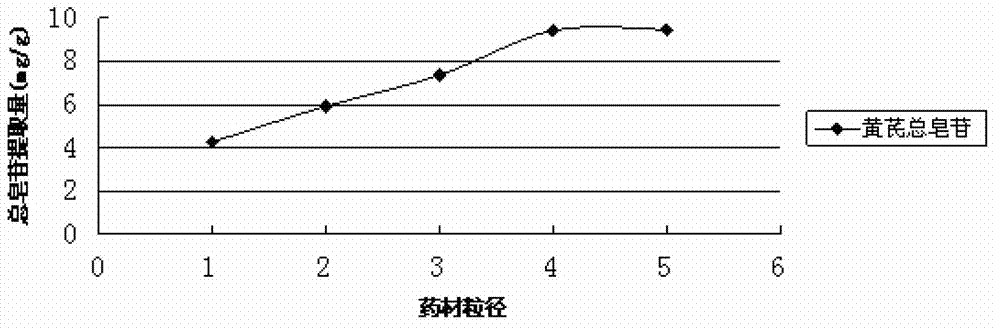

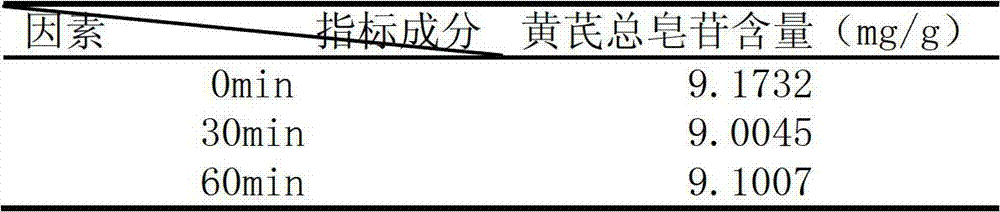

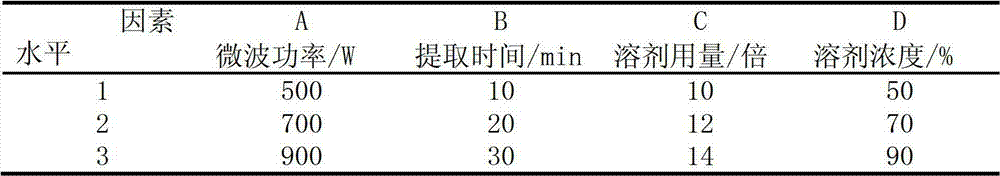

[0023] Embodiment 1 Extraction process parameter screening test of the present invention

[0024] 1 Instruments and reagents

[0025] 1.1 Instrument

[0026] HWC-3 microwave extraction experimental equipment (Tianshui Huayuan Medical Equipment Co., Ltd.); UV-6000 ultraviolet-visible spectrophotometer (Shanghai Meipuda Instrument Co., Ltd.); swinging high-speed universal pulverizer (DFY-300, Wenling City Linda Machinery Co., Ltd.); rotary evaporator (RE52CS-1 type, Shanghai Yarong Biochemical Instrument Factory); vacuum drying oven (DZG-6020 type, Shanghai Senxin Experimental Instrument Co., Ltd.); BP61 electronic balance (ten thousandth 1, Germany Satorius); electronic balance (BP211D type, one hundred thousandth, Germany Satorius); UPT-I-10T ultra-pure water device (Chengdu Ultra Pure Technology Co., Ltd.); constant temperature water bath (Jintan City Hongke instrument factory); pipette guns of various models.

[0027] 1.2 Reagent

[0028] Astragalus medicinal material (p...

Embodiment 2

[0083] Example 2 Extraction process of astragalus saponins and astragalus polysaccharides of the present invention

[0084] Precisely weigh 10 grams of astragalus powder (passed through a No. 2 sieve), put it in a microwave extraction device, microwave power 900W, keep the temperature at 70°C, extract 3 times in total, add 158mL of 50% ethanol for the first time, and extract for 10 minutes; the second time Add 140mL of 50% ethanol solution and extract for 10min; add 140mL of distilled water for the third time and extract for 20min. Put the extraction solution in a suction filtration device for suction filtration, transfer the first two extractions to a rotary evaporator, concentrate to a certain volume, add the third extraction, concentrate to about 60mL, add distilled water to a 100mL volumetric flask, and use phenol-sulfuric acid method The content of astragalus polysaccharide in the extract was determined to be 1.720g, the yield was 18.49%, and the extraction rate was 65.32...

Embodiment 3

[0098] Example 3 Extraction process of astragalus saponins and astragalus polysaccharides of the present invention

[0099] Precisely weigh 10 grams of astragalus powder (passed through a No. 2 sieve), put it in a microwave extraction device, microwave power 500W, keep the temperature at 70°C, extract 3 times in total, add 118mL of 50% ethanol for the first time, and extract for 10 minutes; the second time Add 100mL of 50% ethanol solution and extract for 10min; add 100mL distilled water for the third time and extract for 20min. Put the extraction solution in a suction filtration device for suction filtration, transfer the first two extractions to a rotary evaporator, concentrate to a certain volume, add the third extraction, concentrate to about 60mL, add distilled water to a 100mL volumetric flask, and use phenol-sulfuric acid method The content of astragalus polysaccharide in the extract was determined to be 1.772g, the yield was 19.05%, and the extraction rate was 67.30%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com