Panicum miliaceum nutrition milk and preparation method thereof

A technology of glutinous millet and nutrition, which is applied in the field of grain beverage processing, glutinous millet nutritional milk and its preparation, and glutinous millet nutritional milk, can solve the problems of low lysine content, achieve rich nutrition, delicate taste, and broaden the consumer population Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

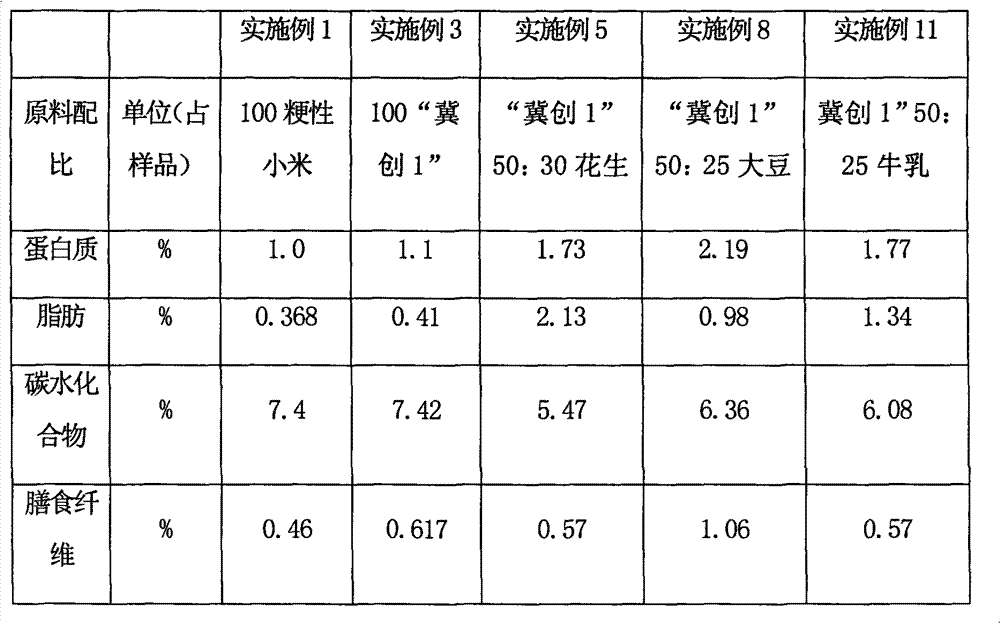

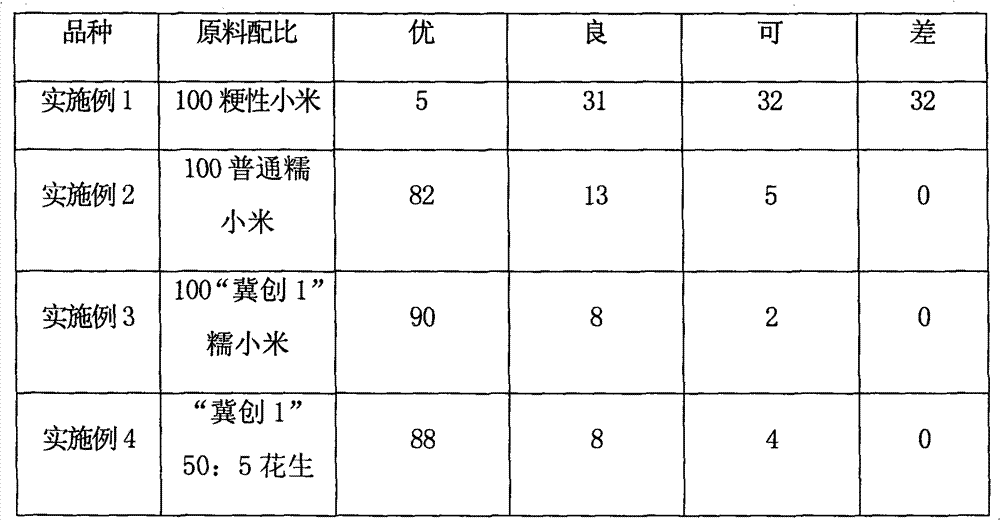

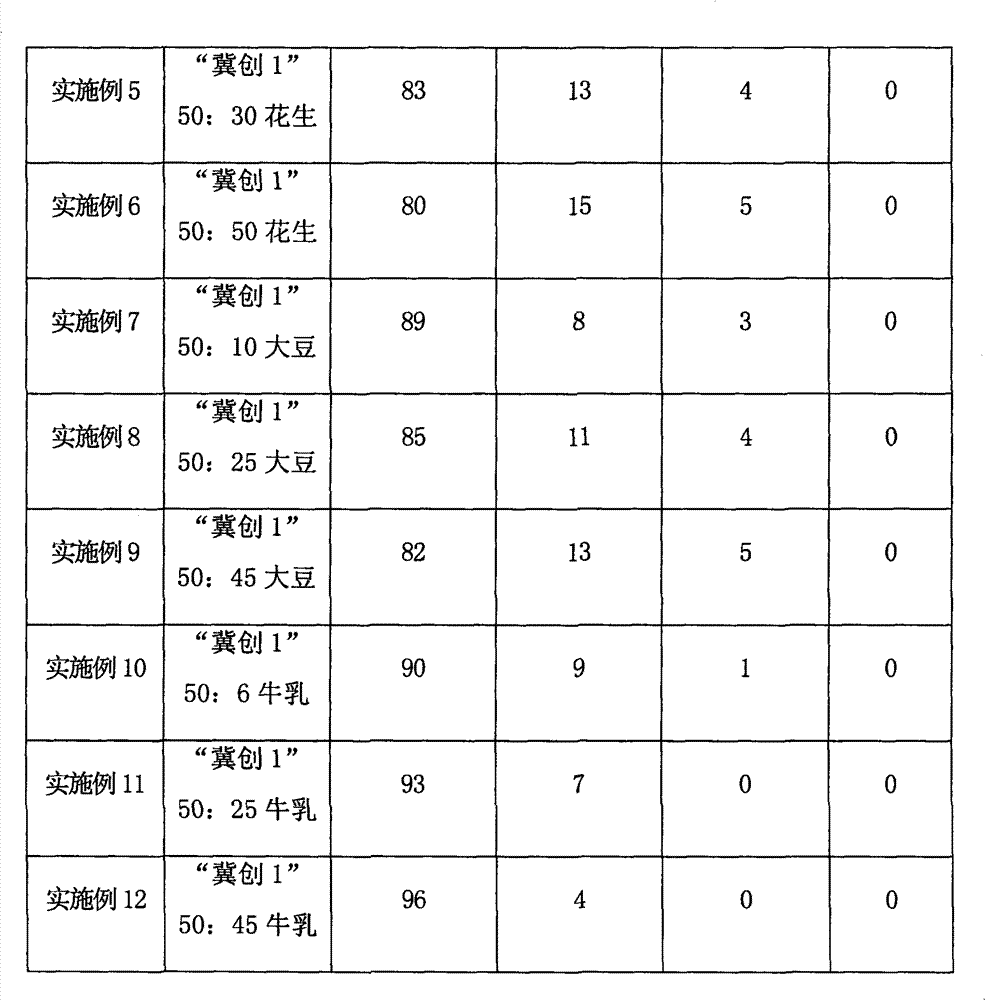

Examples

Embodiment 1

[0032] Weigh 100 parts by weight of japonica millet, soak the rice with 2 times the weight of water at room temperature, take it out after 24 hours, add water to the millet and water according to the weight ratio of 1:8, and grind it on a self-partitioning grinding wheel. Standby; heat gelatinization at 70°C for 15 minutes; coarsely grind the millet paste after gelatinization, and then perform colloidal fine grinding; degas the refined rice slurry through a vacuum degasser, and vacuum It is 0.8Mpa and the center temperature is 90℃; the slurry temperature before homogenization is lower than 50℃, and the pressure of 18MPa is selected for homogenization; the homogenized emulsion is subjected to high temperature and high pressure sterilization at 121℃, 20 minutes, killing The germs and spoilage bacteria are quickly cooled to 38°C after exiting the sterilization pot to prepare the millet nutritional milk of the present invention.

Embodiment 2

[0034] Weigh 100 parts by weight of ordinary glutinous millet, soak the rice in 2 times the weight of water at room temperature, take it out after 24 hours, add water to the millet and water according to the weight ratio of 1:8, and grind it on a self-partitioning grinding wheel. Standby; heat gelatinization at 70°C for 15 minutes; coarsely grind the millet paste after gelatinization, and then perform colloidal fine grinding; degas the refined rice slurry through a vacuum degasser, and vacuum It is 0.8Mpa and the center temperature is 90℃; the slurry temperature before homogenization is lower than 50℃, and the pressure of 18MPa is selected for homogenization; the homogenized emulsion is subjected to high temperature and high pressure sterilization at 121℃, 20 minutes, killing The pathogens and spoilage bacteria are quickly cooled to 38°C after exiting the sterilization pot to prepare the glutinous millet nutritional milk of the present invention.

Embodiment 3

[0036] Weigh 100 parts by weight of "Jichuang 1" glutinous millet, soak the rice with 2 times the weight of water at room temperature, take it out after 24 hours, add water to the millet and water in a ratio of 1:9, and grind on a self-partition grinding wheel mill , Homogenized for use; heat gelatinization at 70°C for 15 minutes; coarsely grind the milled rice paste after gelatinization, and then perform colloidal fine grinding; degas the refined rice slurry through a vacuum degasser , The vacuum degree is 0.8Mpa, the center temperature is 90℃; the slurry temperature before homogenization is required to be lower than 50℃, and the pressure of 18MPa is selected for homogenization; the homogenized emulsion is subjected to high temperature and high pressure sterilization at 121℃, 15 minutes , Kills pathogenic bacteria and spoilage bacteria, and quickly cools to 38°C after leaving the sterilization pot to prepare the glutinous millet nutritional milk of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com