Aqueous primer composition and coating method using same

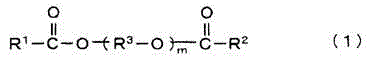

A water-based primer and composition technology, applied in primers, devices for coating liquids on surfaces, coatings, etc., can solve the problem of reduced water resistance of multi-layer coatings, inability to obtain sufficient paintability, and white base coats Achieves the effect of excellent water resistance by eliminating problems such as reduced electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] With the aqueous dispersion (A-1) (note 1) of 30 parts of modified polyolefins in terms of solid content mass, 25 parts of water-based acrylic resin (B-1) (note 4) in terms of solid content mass, in solid 25 parts of water-based acrylic resin (B-2) (Note 5) in terms of component mass, 20 parts of blocked polyisocyanate compounds (C-1) (Note 7) in terms of solid content mass and 150 parts of conductive pigments (D- 1) (Note 9) Mix according to the conventional method, dilute with deionized water to make the solid content 40%, and prepare the water-based primer (1).

Embodiment 2~13 and comparative example 1~6

[0117] Except that the blending composition in Example 1 was set as shown in the following Table 1, the same operation was performed as in Example 1 to obtain water-based primers (2)-(19). The storage stability of each prepared water-based primer was evaluated. The results are also shown in Table 1 below.

[0118] The blends in Table 1 are expressed in terms of solid content, and (Note 1) to (Note 15) in Table 1 are as follows.

[0119] (Note 1) Aqueous dispersion (A-1) of modified polyolefin: 8% by mass of maleic acid was added to an ethylene-propylene copolymer (5% ethylene content) produced using a metallocene catalyst. Modified polyolefin obtained by modification with dimethyl ethanolamine has a melting point of 80°C, a Mw of about 100,000, and a Mw / Mn of about 2.1. A dispersion obtained by water dispersion using 10 parts of emulsifier.

[0120] (Note 2) Aqueous dispersion of modified polyolefin (A-2): "Hardlen (Hardlen) NA-3002", aqueous dispersion of non-chlorinated pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com