Cylindrical power battery module structure

A power battery and module structure technology, which is applied in battery pack parts, structural parts, secondary battery manufacturing, etc., can solve the problems of high self-consumption, low reliability of battery electrical connection, and large internal resistance of battery packs. Achieve the effect of short height, easy standardized design and large connection surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

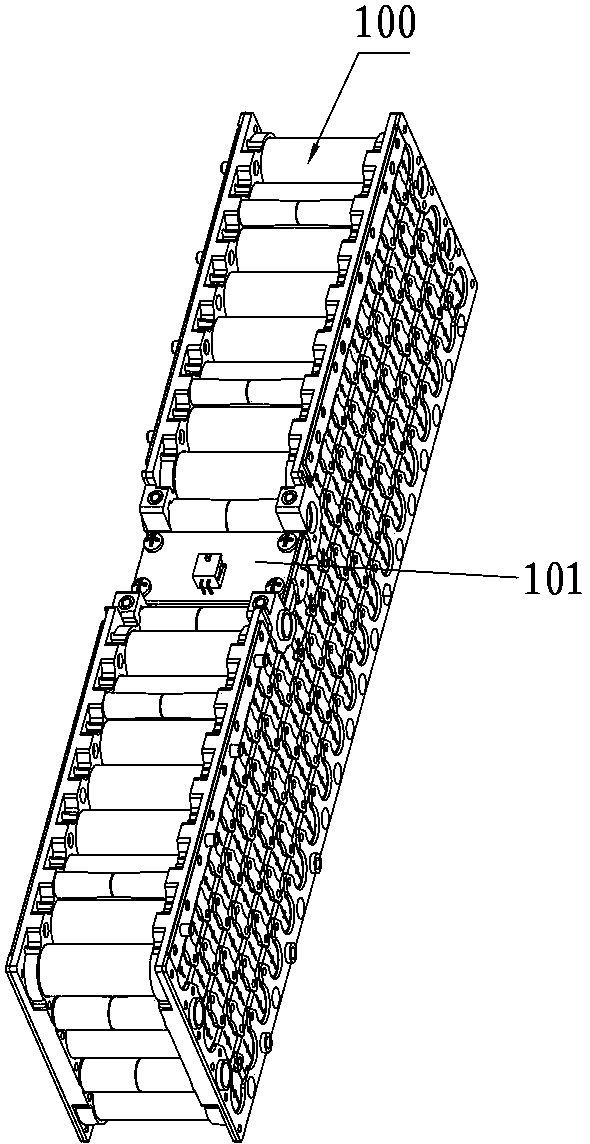

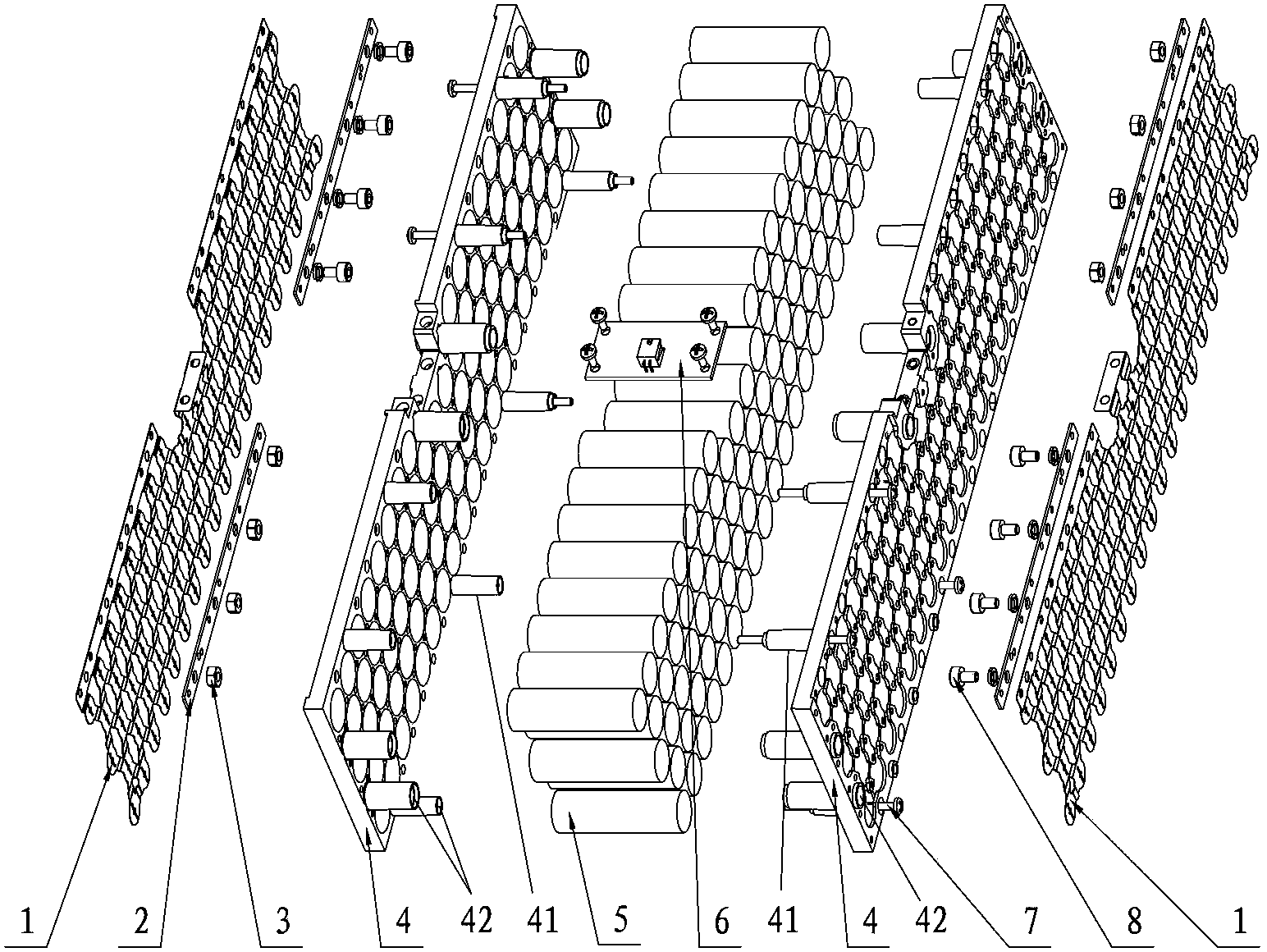

[0028] Such as Figure 1 to Figure 6 As shown, the cylindrical power battery module structure of the present invention includes at least two battery modules 100 connected in series. The battery module 100 includes:

[0029] The battery pack includes cylindrical batteries 5 of the same type arranged in parallel and at intervals. Usually, the same electrodes of each battery 5 of each battery pack are located on the same side, and the batteries in the battery pack can also be divided into two groups, three groups, etc. according to needs, and the same electrodes of the batteries in each group are located on the same side , Different groups of batteries can be located on the same side or on different sides as needed.

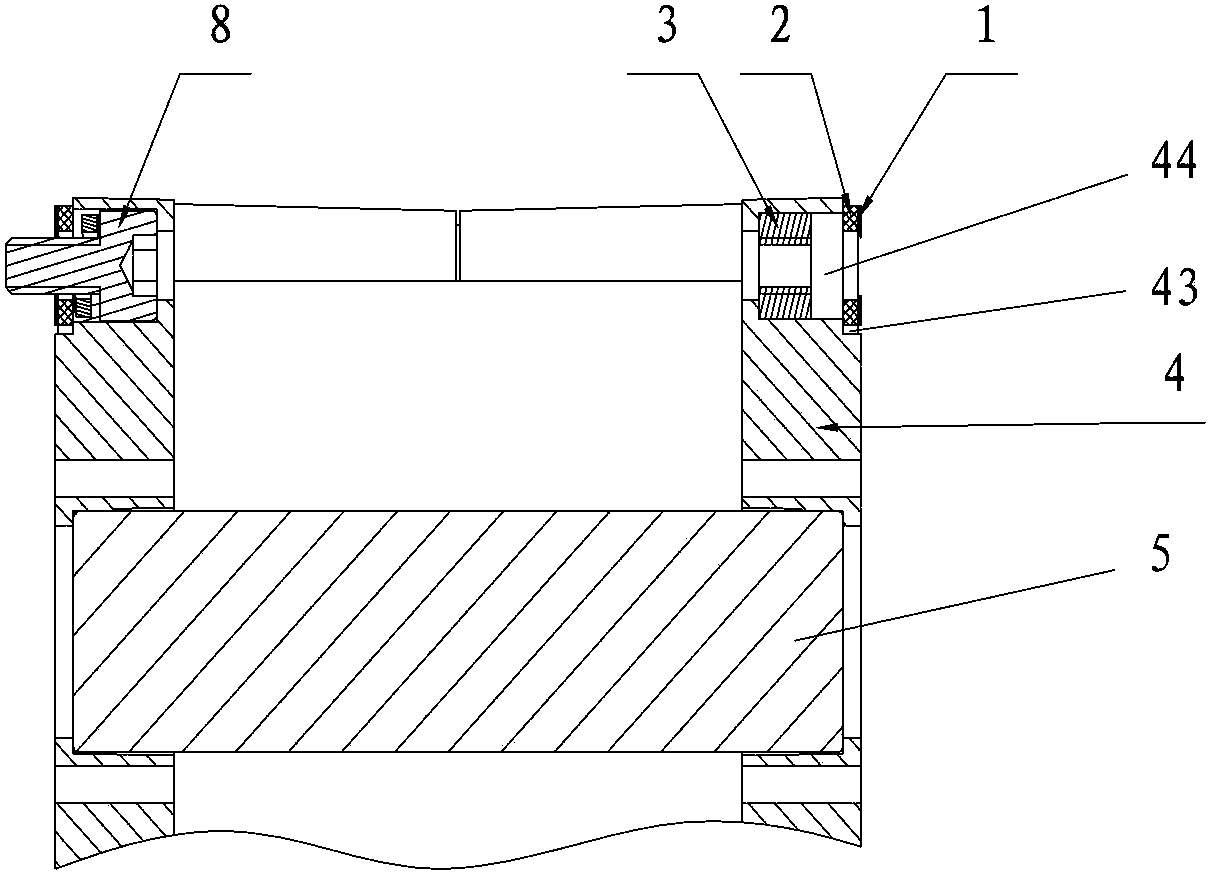

[0030] Cell support 4. The two cell holders 4 are located on both sides of the electrodes of the cell group to clamp the cell group and connect and fix it. The opposite side of the battery support 4 (that is, the inner side of the battery support) includes the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com